How to Select the Best Vehicle Connectors for Your Needs

When picking vehicle connectors for your car, it's more than just wires. The right connectors help your car work safely and smoothly. Factors like size, power, and flexibility are important. Connectors must handle shaking, heat, cold, and dirt. Choosing the right vehicle connectors is very important.

Key Takeaways

Understand the electrical needs of your vehicle connectors by matching them to your system's voltage and current limits to ensure safe and efficient operation.

Choose connectors that are compact yet durable, as modern vehicles require small designs that can withstand harsh conditions like heat, water, and vibrations.

Always look for industry certifications when selecting connectors, as these ensure safety, reliability, and performance in demanding automotive environments.

Electrical Needs for Vehicle Connectors

Picking the right vehicle connectors means knowing their electrical needs. This helps them handle power and signals without problems. Let’s simplify it.

Voltage and Current Basics

Voltage and current are key for any connector. They show how much power it can safely manage. Most car connectors work with systems under 300 volts. Current depends on things like contact size and heat transfer. Here's a quick summary:

Aspect | Details |

|---|---|

Voltage Limit | Works with systems under 300 volts. |

Current Limit | Tested by raising current until max heat is reached. |

Current Factors | Includes contact size, heat transfer, and temperature. |

Why is this important? Going over voltage can cause sparks or damage. Exceeding current makes resistance rise, causing failures. To prevent this:

Match the connector to your system's current.

Stay within the voltage limit for safety.

Signal Types and Matching

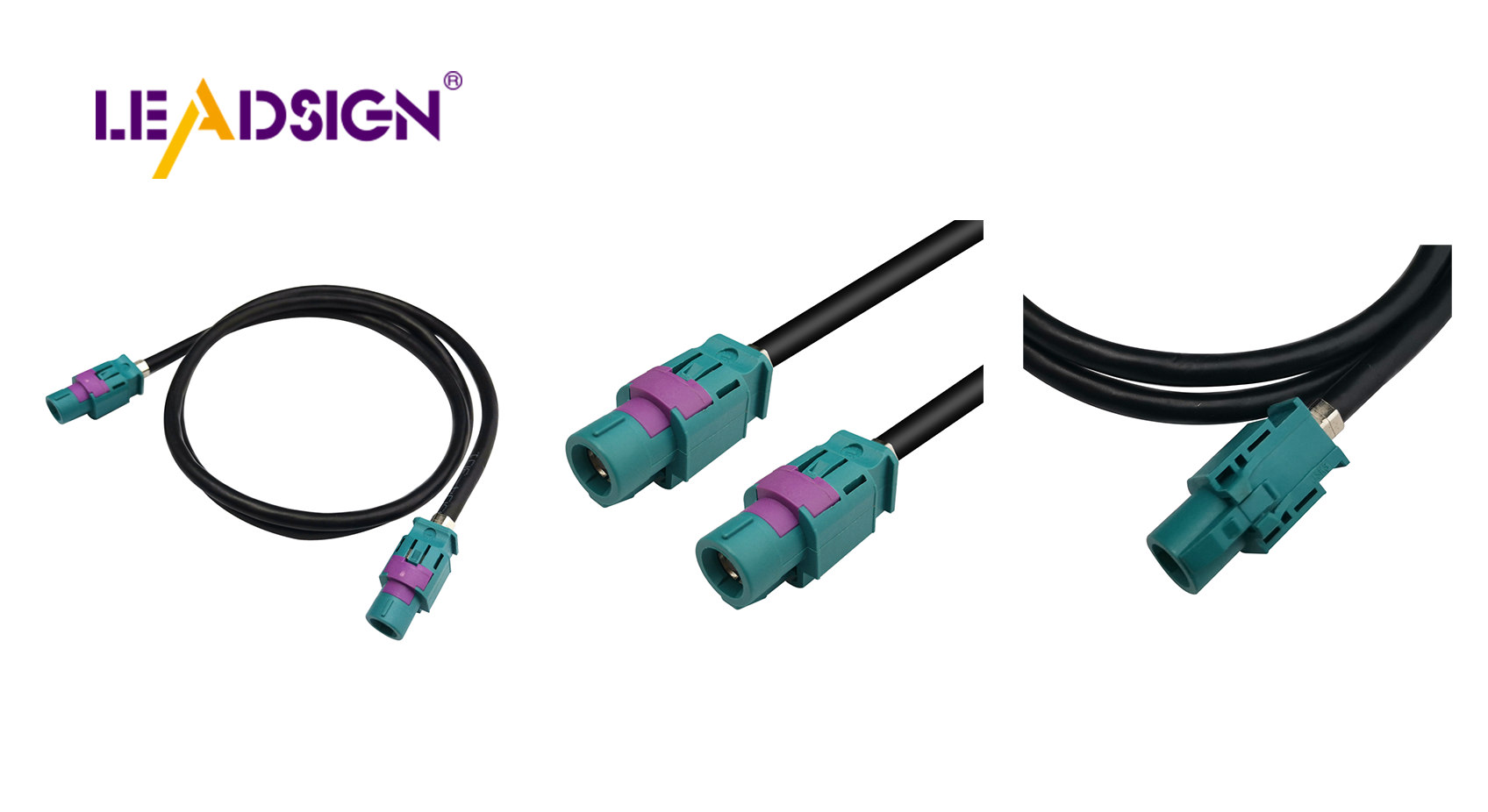

Connectors handle different signals. Some are for fast data, like USB or Ethernet. Others work with low-power signals for cameras or screens. For example, HSD connectors send fast data for car electronics. They work with USB 3.0, Ethernet, and LVDS signals.

When choosing a connector, think about the signal type. Is it digital or analog? Does it need to send fast data? Picking the right one keeps everything working smoothly.

Size and Space Considerations

The size of connectors is more important than it seems. Cars today have more electronics in smaller spaces. Picking the right size is very important. Let’s see how small designs and good performance help.

Small Designs for Tight Spaces

Have you noticed cars are getting smarter and cooler? They now have sensors, cameras, and fancy screens. This means space inside cars is limited. Small connectors are great for these tight spaces. They fit well and still work perfectly.

Car makers are making smaller connectors that do more jobs. These tiny designs save up to 25% more space than older ones. The extra space helps make better car layouts and designs.

Some small connectors can even handle tough conditions like dirt and water. They meet strict rules like IP69K. These connectors are small but strong, perfect for modern cars.

Balancing Size with Performance

You might think smaller connectors don’t work as well, but they do. Today’s small connectors are strong and work great. They handle fast data and power, even in tough spots.

For example, small round connectors are made to last and work well. They’re great for things like USB, Ethernet, and LVDS. Picking the right connector keeps your car working well without wasting space.

Environmental Factors for Vehicle Connectors

Vehicle connectors must work well in tough environments. Let’s see how heat, water, and shaking affect them and what to check for durability.

Handling Temperature Changes

Extreme temperatures can harm vehicle connectors. Hot weather can make materials expand, causing weak connections or letting water in. Cold weather can make them crack or break easily. These changes can mess up your car’s systems.

To fix this, makers use materials like copper or aluminum to manage heat. Heat-resistant plastics also help connectors stay strong. Some designs even have heat sinks to cool them down. Always choose connectors that can handle your car’s temperature range.

Keeping Out Water and Dirt

Water and dirt can ruin vehicle connectors. Without protection, they can cause rust or short circuits. That’s why sealing is very important.

Pick connectors with strong seals like rubber gaskets or O-rings. Some connectors meet IP69K standards, meaning they block high-pressure water sprays. These seals keep connectors clean and dry, even in bad conditions.

Staying Strong Against Shaking

Cars shake a lot from engines or bumpy roads. This can loosen connectors and cause problems.

To stop this, connectors have locks to keep them tight. Good materials also absorb shocks, making them last longer. If your car faces rough roads, pick connectors made for tough rides.

Following Industry Rules

When picking vehicle connectors, don’t ignore industry rules. These rules make sure connectors are safe, reliable, and work well. Let’s see why certifications are important and how they help.

Why Certifications Matter

Certifications are like a badge showing connectors passed tough tests. They prove the product meets important safety and quality standards. Here are some key certifications to know:

JB 2436.1: For copper crimp terminals

UL 486A-B: For terminal blocks

UL 486E: For aluminum and copper terminal blocks

JIS C2805: For copper wire crimp terminals

GB 34989: For connector safety and testing

UL 1977: For data and high-current connectors

IEC 61984: For connector safety and testing

QC/T 1067: For car wiring harness connectors

USCAR 2: For car electronic connector performance

GB/T 20234.1: For electric car charging connectors

These certifications show connectors can handle tasks like sending power or data safely.

Making Sure They’re Safe

You need connectors that fit your car’s systems perfectly. Certifications help by testing them for heat, shaking, and sealing. Higher ratings mean they can handle tough conditions like hot weather or bumpy roads.

Testing also checks for problems like water leaks or power failures. A connector with a strong seal keeps out dirt and water, lasting longer. By choosing certified connectors, you keep your car safe and working well.

Strong and Long-Lasting Vehicle Connectors

Vehicle connectors must be strong and last a long time. They should work well even in tough conditions. Let’s see what helps them stay reliable.

How Long Connectors Last

Each time you plug or unplug a connector, it wears out a bit. This is called a mating cycle. Over time, too many cycles can weaken the connector. Makers test connectors to handle thousands of cycles without problems. This is important because frequent use can cause loose connections or failures.

Connectors fail more often in high heat or with heavy use. For example:

At 140°C, failure rates are 15 times higher.

To avoid problems, pick connectors made for your car’s needs. Choose ones tested for wear, electrical issues, and frequent use.

Materials That Last Longer

The materials in connectors affect how long they last. Good materials resist rust and damage. Special lubricants protect connectors from water, dirt, and air. These coatings slow rust and keep connectors working well.

High-quality materials also stop damage from gases or oxygen. Picking connectors with these features means they’ll stay strong for years.

Types of Connections for Vehicle Connectors

How you connect vehicle connectors is very important. The way they are attached affects how well they work. Let’s look at common connection types and their features.

Crimped Connections

Crimped connections are often used in vehicles. This method squeezes a metal sleeve onto a wire. It creates a strong and secure connection.

Here’s why crimped connections are popular:

They are quick and easy to make.

They block out water, dust, and dirt.

They handle heat and shaking without breaking.

But crimping has some downsides. Special tools are needed, which can cost a lot. If done wrong, the connection might fail. When done right, crimped connections last a long time.

Soldered Connections

Soldering is another way to connect wires. It melts solder to join wires and connectors. This makes a strong and lasting bond.

Soldered connections are very reliable but need more time and skill. You’ll need heat and steady hands to avoid mistakes. While slower than crimping, soldering is great for stable connections.

Connection Type | Strength | Ease of Use |

|---|---|---|

Soldered | Very strong but takes longer | Needs heat and skill |

Crimped |

Push-In and Other Methods

Push-in connections are becoming more common in cars. No tools are needed. You just push the wire in, and it locks.

This method is great for small spaces and quick setups. It’s part of the trend for smaller, smarter connectors. These designs save space and still work well. Some even protect against water and dirt.

New features like surge filters and interference protection make push-in connectors better. They are a good choice for easy and modern solutions.

Picking the right connectors for your car is important. They help keep your car safe and working well. Choose connectors that manage power, fit small spaces, and last long. Make sure they can handle tough weather and rough roads. Check for certifications and ask experts for advice. Good connectors make your car reliable and improve your driving.

FAQ

What are the main types of vehicle connectors?

Crimped, soldered, and push-in connectors are common. Each type has its own advantages, like being strong, easy to use, or fast to install.

How can I tell if a connector is waterproof?

Check for IP ratings, such as IP69K. These ratings mean the connector can block water, dirt, and other harmful stuff in tough conditions.

Can one connector work for both power and data?

Yes, some connectors, like HSD ones, do both jobs. They are made for fast data and power, making them useful for today’s cars.

See Also

Enhancing Automotive Performance Using HFM Connectors

Why Fakra Connectors Are Essential for Today's Vehicles

Improving Data Transfer in Cars with Advanced Connectors