How to Repair and Replace Vehicle Connectors for Better Performance

Vehicle connectors are important for your car's electrical systems. Broken connectors can cause fires or damage your car. They might also lower performance or create safety problems. The right vehicle connector keeps connections strong and avoids these issues. Checking them often keeps your car safe and working well.

Key Takeaways

Regularly check your vehicle connectors to prevent electrical issues and ensure safety. Aim to inspect them at least twice a year.

Use the right tools for replacing connectors, including wire strippers, crimping tools, and a multimeter, to ensure a safe and effective installation.

Always test the new connector after installation to confirm proper function and avoid future problems. A multimeter is essential for checking resistance and continuity.

Finding Bad Car Electrical Connectors

Signs of Damage or Wear

You can find bad car connectors by checking for problems. Pins may wear out from being used a lot. Rust or dirt can build up if connectors get wet. These problems make signals weaker or stop them. Bent or old connectors might not press together well, causing loose connections. Driving bumps and shakes can loosen parts or break them inside. Pushing too hard when installing can bend or snap pins. Checking for these problems often keeps your car running smoothly.

Tools for Finding Car Electrical Connectors

To find car connectors, you need the right tools. Start by looking at the connector’s shape and size. Check for labels to know the type. This is easy and doesn’t need special tools. For more details, use a multimeter to check if it works. This tool tests if signals pass through correctly. Advanced tools like scanners can check connectors better. These tools make finding car connectors faster and easier.

Why Connectors Fail

Car connectors fail for many reasons. Using them a lot can wear them out. Rust or dirt from water can make them work poorly. Bent connectors or weak pressure can cause signal issues. Driving bumps can loosen or break parts inside. Forcing connectors during setup can also break them. Knowing these reasons helps you avoid problems and choose good connectors.

Getting Ready to Change a Wire Harness Plug Connector

Staying Safe

Safety is very important when fixing wire harness connectors. Follow these steps to stay safe:

Use rubber covers to stop terminal surfaces from rusting.

Secure connectors on moving parts to avoid damage from shaking.

Check rubber parts to make sure they don’t come apart.

Don’t squeeze wires during crashes to prevent fires or shorts.

Keep connectors away from water, oil, or wet areas.

Also, look for risks before starting. Use proper tools and follow safety rules. Work with others if you can and report problems quickly. Being safe helps the job go well and avoids accidents.

Tools and Supplies You’ll Need

Having the right tools is key for replacing connectors. Here’s what you’ll need:

New connectors that match the old ones.

Flathead and Phillips screwdrivers for screws.

A multimeter to check if connections work.

Heat shrink tubing and tape to cover wires.

Cable ties to keep wires neat and secure.

Heat guns to seal heat shrink tubing.

Sleeves to protect wires even more.

Getting these tools ready helps you finish the job safely and quickly.

Setting Up Your Workspace

A clean workspace makes changing connectors easier. Clear away extra stuff first. Make sure the area has good light to see small parts. Put tools and supplies where you can reach them. Use a flat, clean surface so you don’t lose tiny pieces.

Label wires before taking them apart to avoid mix-ups later. Keep a small container nearby for screws and little parts. This setup saves time and helps you avoid mistakes. A neat workspace also keeps you focused and safe while working.

Step-by-Step Guide to Replacing Vehicle Connectors

Taking Out the Old Connector

Follow these steps to remove the old connector:

Gather tools like a multimeter, wire cutters, and crimping tools.

Disconnect the car battery. Loosen the negative terminal first, then the positive. Wear gloves and safety glasses.

Check the wire harness plug connector for damage or wear. Confirm it needs replacing.

Press the release tab or unscrew the connector gently. Avoid harming nearby wires.

Compare the new connector with the old one. Make sure pins and tabs match.

Carefully removing the old connector avoids damage and helps replacement go smoothly.

Putting in the New Wire Harness Plug Connector

When installing the new connector, follow these steps:

Clean your workspace and ensure it is bright.

Strip wire ends to the right length. Remove insulation carefully to avoid cutting wires.

Use a crimping tool to attach terminals tightly to wires. Place terminals into the connector housing correctly.

Test the connection with a multimeter to check if it works.

Attach the connector to the harness. Cover wires with heat shrink tubing or tape to stop short circuits.

Installing the connector properly ensures the wire harness works well.

Checking the Connection for Proper Function

After installation, test the connection to make sure it works:

Use a multimeter to check resistance and continuity. This confirms the connector is working.

Reconnect the car battery. Start with the positive terminal, then the negative.

Test the electrical parts linked to the wire harness plug connector. Make sure they work.

If there are problems, check for loose wires or wrong connections. Use the multimeter again to confirm electrical flow.

Testing ensures the new connector is installed right and the car’s system works well.

💡 Tip: Don’t skip testing or use the wrong connectors. These mistakes can cause problems or safety risks.

Troubleshooting and Ensuring Performance

Testing the New Connector

After changing a wire harness plug connector, testing is important. It helps make sure your car works well. Use tools made for fast and accurate testing. Precision RF connectors are great for wireless systems. They keep signals steady. For car connectors, Severe Environment Testing (SET) checks if they work in tough conditions.

A multimeter can measure resistance and check if wires connect properly. For advanced systems, high-speed connectors like Samtec's are useful. They work well for board-to-board setups. Tests like vibration, heat changes, and water exposure check if the connector is strong. These tests show how it will perform in real life.

Testing makes sure the new connector fits with the wire harness. It also stops problems from happening later. Always use the right tools for the system to get good results.

Fixing Common Problems After Replacement

Sometimes, replacing a plug connector causes issues. One problem is using the wrong or cheap connectors. This can lead to electrical failures. Always pick connectors that match OEM standards to avoid this. Broken or rusty pins can also stop connections. Check pins closely and change them if needed.

Using the wrong tools is another common mistake. Bad tools can harm the connector or wires. Use tools made for car electrical connectors. If wires are loose or connections are weak, check the setup again. Make sure everything is tight and secure.

Fixing these problems helps the wire harness plug connector work well. Regular checks and careful fixes stop future issues. This keeps your car running smoothly.

💡 Tip: Test the connection fully and use good tools for repairs.

Checking car connectors often keeps your car safe and working well. Bad connectors can cause problems with important systems. Changing broken connectors stops sudden issues and helps parts like lights and airbags work. Take care of connectors to drive safely and with confidence.

FAQ

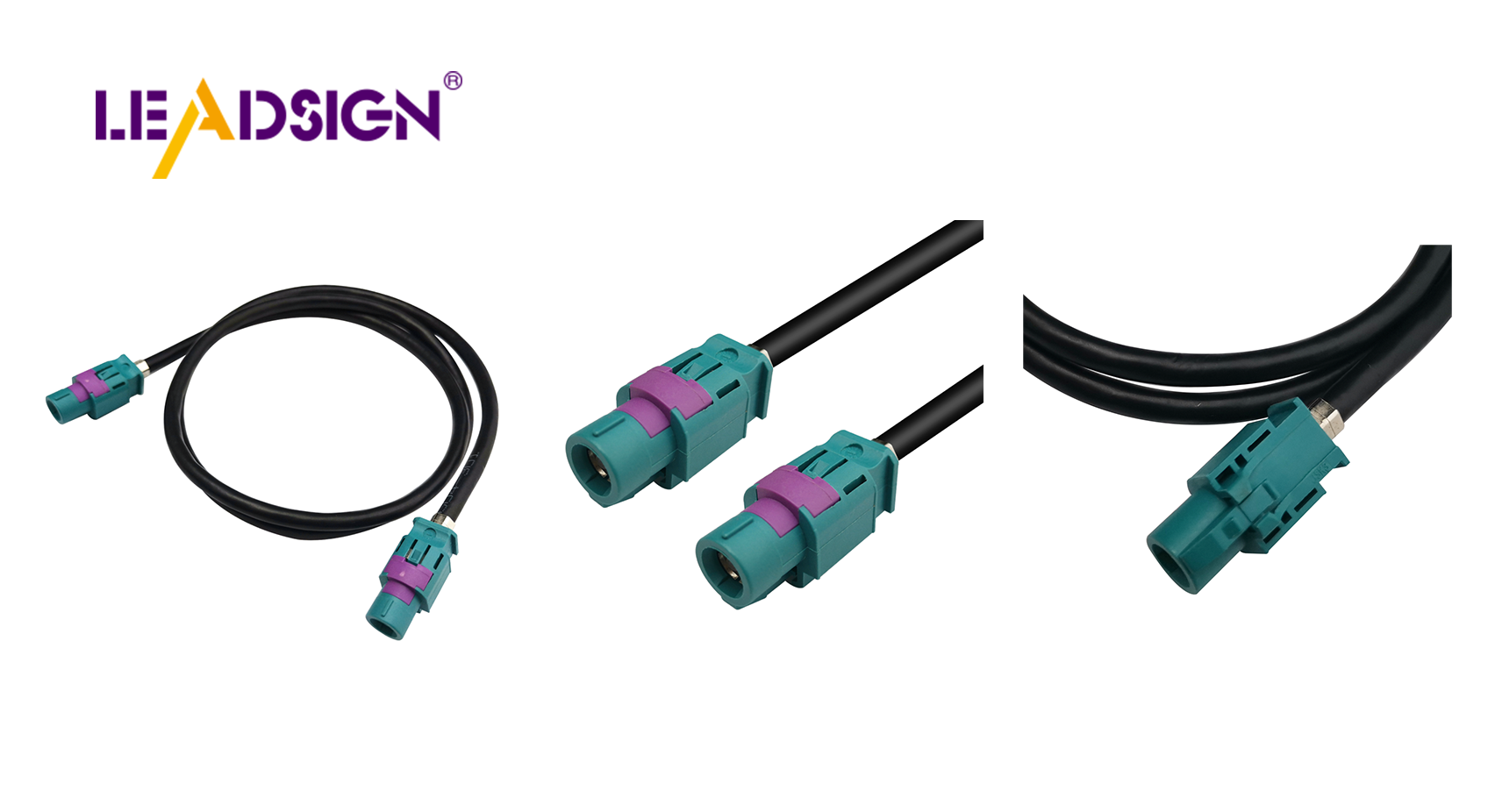

Why use high-speed connectors like HSD connectors?

High-speed connectors, like HSD connectors, send data quickly and steadily. They are great for car electronics, entertainment systems, and USB ports. These connectors improve how your car works.

💡 Tip: Choose HSD connectors for strong links in tough conditions.

How often should you check car connectors?

Check your car connectors twice a year. Regular checks find rust, damage, or wear early. This stops electrical problems and keeps your car working well.

Can you change a car connector by yourself?

Yes, you can do it on your own. Be safe, use proper tools, and test the connection after replacing it to make sure it works.

⚠️ Note: Get expert help if you feel unsure.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Boosting Data Transfer Efficiency With Fast Automotive Connectors

Significance of Fakra Connectors for Honda Cars

Fakra Connectors: Essential for Today's Automotive Technology

Transforming Vehicle Connectivity With HFM Connector Benefits