How to Identify and Replace Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for your car's electrical system. They facilitate communication between electronic components, ensuring a seamless driving experience. There are various types of automotive electrical connectors, each designed for specific functions. Proper maintenance of these connectors is essential. Routine inspections can prevent costly repairs and maintain the safety of the vehicle. Automotive connectors consist of male (plug) and female (socket) components, with larger pins for increased power capacity. Understanding the different automotive electrical connector types enables you to effectively address any issues and ensure the reliable operation of your vehicle.

Understanding Car Electrical Connectors

Types of Car Electrical Connectors

Car connectors are important for the car's electric system. They help signals move easily between circuits. Here are some common types:

Blade Connectors

Blade connectors are flat and slide into a slot. They are used in cars because they are easy and reliable. They keep connections strong, which is important for electricity flow.

Bullet Connectors

Bullet connectors look like cylinders and fit into sockets. They disconnect quickly, so they're good when you need to unplug wires often.

Pin Connectors

Pin connectors have pins that go into sockets. They're used in many car parts. Their design lets them connect many wires at once, which helps with complex systems.

Connector Materials Matter

The material affects how well a connector works and lasts.

Plastic Connectors

Plastic ones are light and don't rust easily. They're good where there's moisture but not great with heat.

Metal Connectors

Metal ones, like copper or brass, conduct electricity well and resist rust. They're best for hot places and make strong connections.

Common Connector Issues

Knowing problems helps keep your car's electric system working well.

Corrosion

Corrosion happens when water and air cause rust, making poor connections. Check often to catch it early.

Wear and Tear

Wear happens from use over time or weather effects. Old connectors can get loose or break, so replace them to keep things working right.

Finding the Right Connector Type

Picking the right automotive electrical connectors types is key for your car's electric system. Knowing which one to use helps you change them correctly and avoid problems.

How to Identify Connectors by Sight

Looking at connectors can help you know what type they are. By noticing certain features, you can pick the right one for your needs.

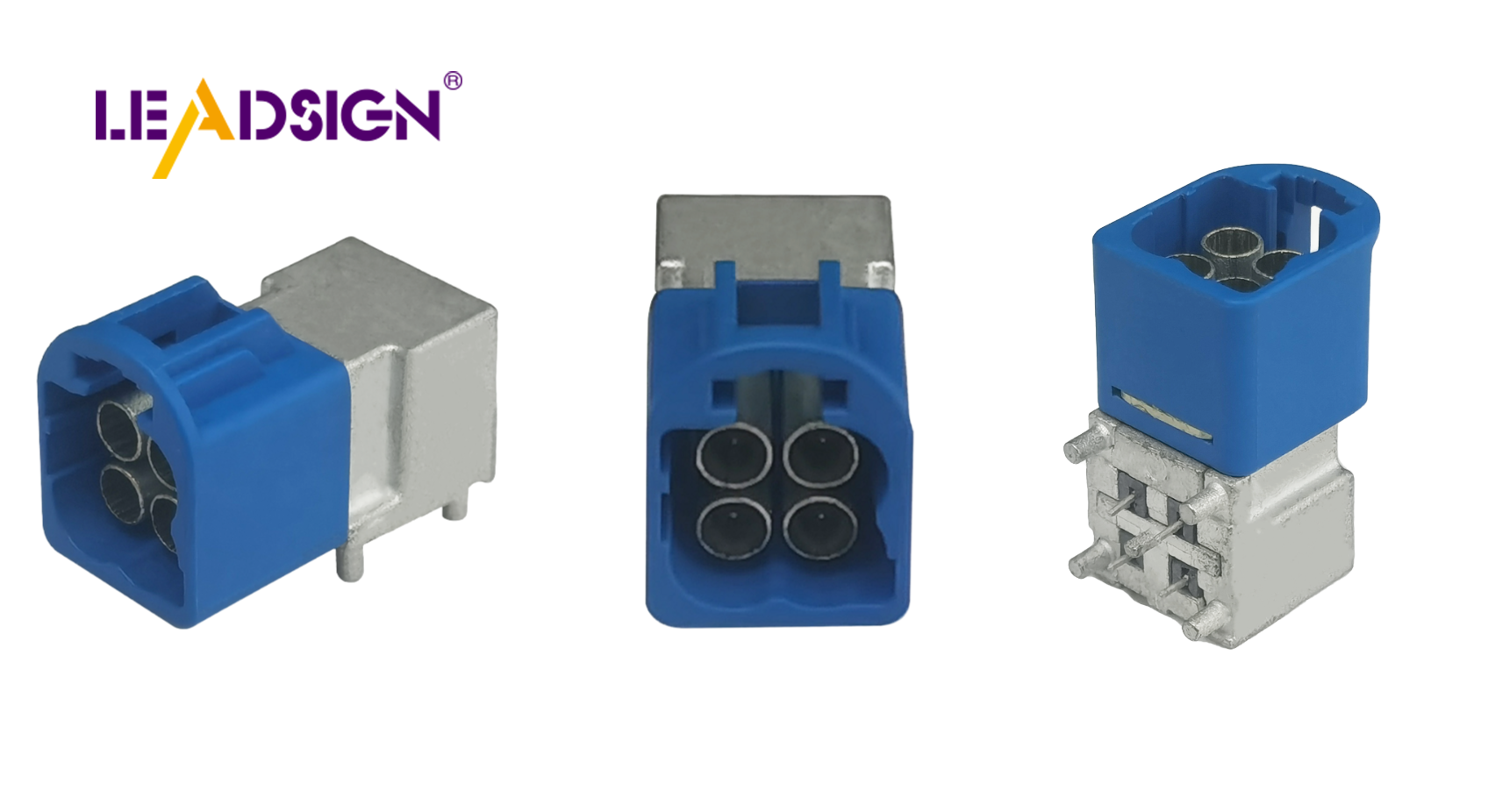

Using Colors

Colors make it easy to tell connectors apart. Makers often use different colors for different jobs or specs. For example, red might mean power, and blue could mean a signal wire. Always check your car's manual to learn what the colors mean.

Shapes and Sizes

The shape and size of connectors give more clues. Some have special shapes like rectangles or circles that set them apart. Measure their size and compare with known sizes to find a match.

Using Books and Guides on Connectors

If looking doesn't work, books and guides can help a lot. They have lots of details about different connectors so you can choose wisely.

Guides from Makers

Makers' guides are full of info about their cars' connectors. These guides usually have pictures and part numbers, helping you find the exact replacement. Always look at the guide for your car's brand and model.

Online Help

The internet has tons of info on automotive electrical connectors types. Car repair sites often have detailed guides and stories from users. These online places can teach you about common connector problems and fixes, helping you understand better.

Expert Testimony:

An Automotive Connectors Expert says, "Soldering is an old way to put in some wire connector types when a strong connection is needed." This shows why picking the right connector type is important for lasting connections.

By using these tips and tools, you can easily find and change car connectors, keeping your vehicle's electric system in good shape.

Steps to Change Car Wiring Connectors

Changing car wiring connectors needs some steps for a good fit. Follow these steps to change connectors in your car.

Getting Ready and Staying Safe

Before starting, get ready and stay safe.

Collecting Needed Tools

First, gather the tools you need. You will need a crimp tool, wire cutters, and a tester. These help with the connectors. A crimp tool is key for crimp connectors because they are easy to use.

Being Safe

Safety matters when working with wires. Unhook the car's battery to stop shocks. Wear goggles and gloves for safety. Keep your work area bright and tidy to avoid accidents.

Taking Out the Old Connector

After getting ready, take out the old connector.

Unplugging the Wires

Carefully unplug the wires from the old connector. Use wire cutters to strip off any covering from wire ends. This gets them ready for new connectors. Be gentle so you don't break them.

Checking for Problems

Check wires and old connector for damage signs like rust or broken parts. Finding these early stops future trouble. If damaged, think about changing those wires too.

Putting in the New Connector

With old one gone, put in a new connector now.

Connecting It Up

Connect new one to wires. For crimp types, put stripped ends into it and use crimp tool to lock them tight. This makes strong bonds that last long time. If using solder ones, melt solder on it carefully without overheating wires.

Testing It Works

Once connected, test it works right with a tester for smooth running of electric system.

By following these steps you can change car wiring connectors well! Knowing different types helps keep your car’s electric system working great!

In this guide, you learned to find and change automotive electrical connectors types. Knowing different connectors and how to replace them keeps your car's electric system working well. Regular care is important. It stops problems like rust and damage that can mess up your car.

Automotive History Insight:

The history of wire connector types shows tech progress. Old cars had simple parts, but new ones have complex systems for fancy electronics.

To change connectors right, use correct tools and stay safe. Have your car's manual nearby for help.

See Also

Exploring HSD Connectors in Automotive Technology

Navigating Ford Fakra Connectors

Significance of Fakra Connectors in Modern Cars