Comprehensive Overview of Wire Connectors Automotive Type

Wire connectors are important in car electrical systems, and understanding the various automotive electrical connectors types is essential. They connect different parts to allow power and signals to flow. Picking the right connectors is key for car performance and safety. Good connectors prevent issues in critical systems like airbags and engines. Different connector types serve specific functions, helping cars operate efficiently. Knowing these types aids in selecting the best connectors for cars to run smoothly.

Types of Automotive Wire Connectors

Knowing different car electrical connectors is important. Each type has a job that helps the car work well and stay safe.

Blade Connectors

Characteristics and Uses

Blade connectors are flat metal pieces that fit into slots. They hold tight, so they’re good for places with lots of shaking. Made from copper or brass, they conduct electricity well and don’t rust easily.

Common Applications in Vehicles

You find blade connectors in fuse boxes. They’re easy to put in and take out, which helps with fixing things. They're also used in lights and other parts needing strong connections.

Bullet Connectors

Characteristics and Uses

Bullet connectors have a round male end that fits into a female socket. This makes them stay connected even if unplugged often. They’re great where you need to connect and disconnect easily.

Common Applications in Vehicles

In cars, bullet connectors are used in audio systems and wiring harnesses. They’re handy when parts need frequent checks or swaps.

Butt Connectors

Characteristics and Uses

Butt connectors join two wires straight together. They help extend wires or link different ones by crimping both ends securely.

Common Applications in Vehicles

Butt connectors fix or install wires in cars. They ensure power flows right through various systems.

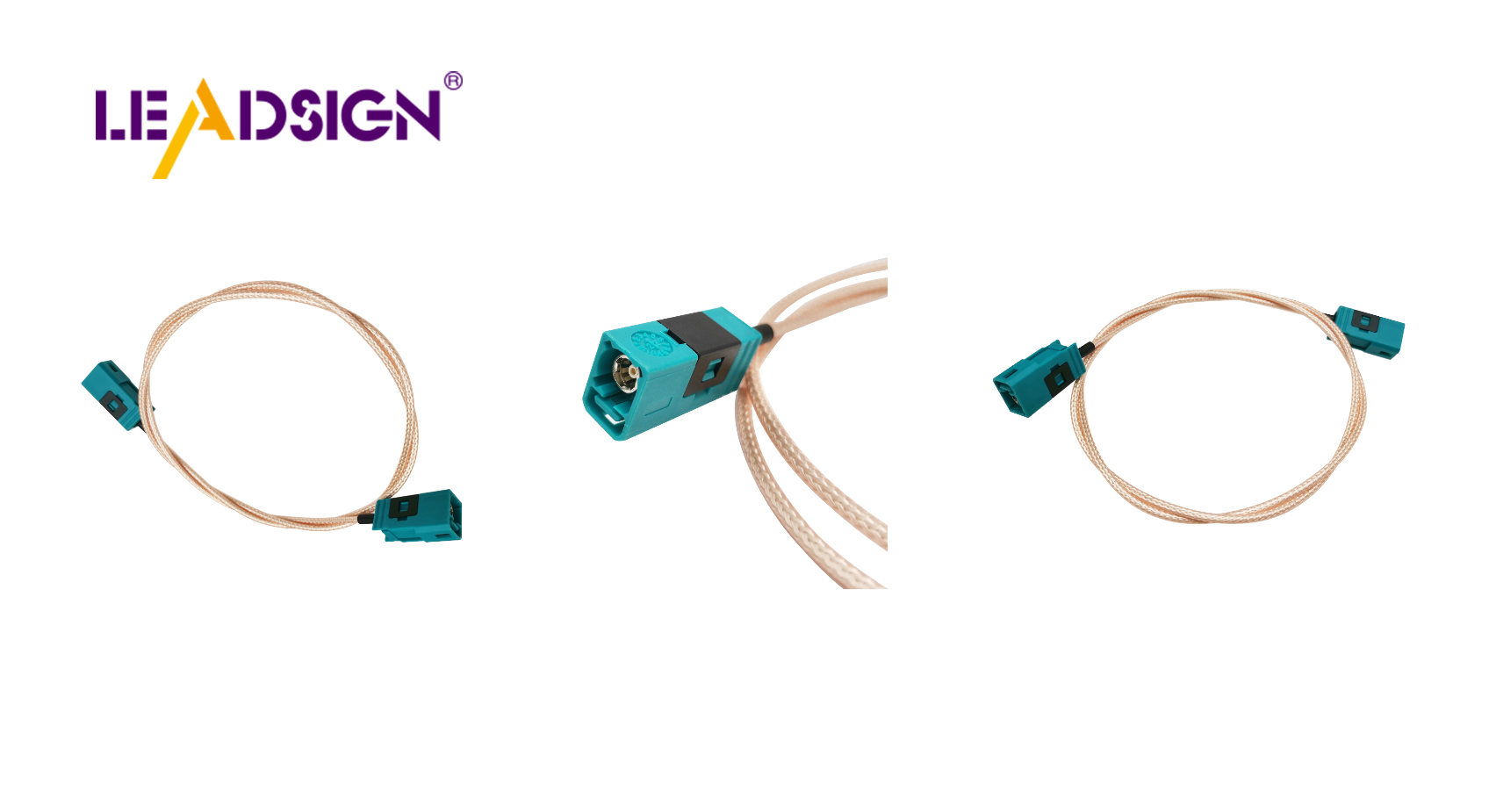

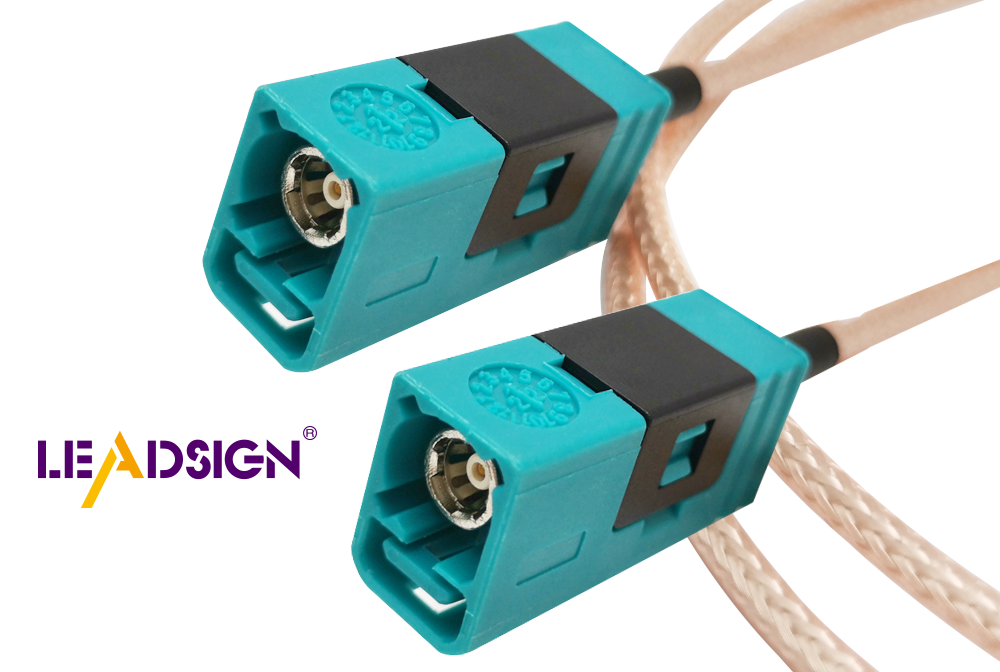

FAKRA Connectors

Characteristics and Uses

FAKRA connectors are used in cars for high-frequency tasks. They connect things like radio antennas and GPS safely. These connectors have a special system to stop wrong connections, making them safe and reliable. With strong locking systems, they stay secure when put together. Made for tough car conditions, they last long and work well.

Product Information:

Impedance: 50 Ω

Frequency range: DC up to 6 GHz

High data rates: Up to 8 Gbps

Temperature range: -40 °C to +105 °C

Mating cycles: ≥ 25

Common Applications in Vehicles

FAKRA connectors are used in many car systems. They help radio antennas give clear sound. GPS systems need these connectors for correct location info. They also support phone calls and Bluetooth use in cars. FAKRA connectors help with keyless entry and heating, making sure these features work smoothly.

Sealed Connectors

Characteristics and Uses

Sealed connectors keep water and dirt away from wires in cars. They protect the car's electrical parts from damage. These connectors often have many pins, keeping connections tight even when it's rough outside. Made from strong stuff like nylon, sealed connectors handle hot or cold weather well.

Product Information:

Material: Nylon

Temperature resistance: Suitable for extreme cold to high heat

Design: Multi-pin for secure connections

Common Applications in Vehicles

Sealed connectors are important where there's lots of dirt or water, like near engines or under the car. They keep brakes and gears working by stopping dirt from getting into wires. Their strong build makes them perfect for hard-to-handle places in cars.

How to Install Car Connectors

Putting car electrical connectors in right makes them last longer. Different ways work for different connectors, needing special tools and steps.

Crimping

Tools and Steps

Crimping means squeezing a connector onto a wire tightly. You need crimping pliers and the right size dies. Pick the correct die so it fits well. Blade and butt connectors use crimping because it's easy and works well.

Tips for Success

Strip Wire Carefully: Take off just enough cover to show wire without hurting it.

Pick Right Connector: Match connector with wire size for best results.

Press Evenly: Push steadily to not break connector or wire.

Soldering

Tools and Steps

Soldering joins parts by melting solder around them. You need a soldering iron, solder, and heat-safe mat. This is good for strong connections in shaky places.

Tips for Success

Clean Parts Well: Make sure wire and connector are clean.

Choose Correct Solder: Use solder that melts at the right temperature for cars.

Don't Overheat: Heat just enough to melt solder without harm.

Heat Shrinking

Tools and Steps

Heat shrinking uses heat to make a plastic tube fit tight over a connector, keeping it safe from water or dirt. Use a heat gun or lighter for this job.

Tips for Success

Get Right Size Tube: Pick a tube that fits snugly over everything.

Heat Evenly: Move heat around tube evenly so it shrinks right.

Check Seal Well: Look for gaps to keep protection strong.

These ways of installing help car connectors work better if done right, making sure they last long in tough car systems.

Maintenance and Troubleshooting

Taking care of car electrical connectors keeps them working well. Regular checks stop many common problems.

Common Problems and Solutions

Finding Bad Connections

Bad connections can cause electrical issues. Signs are flickering lights or power loss. Check connectors for rust, loose parts, or broken wires. Use a multimeter to find problem spots by testing for continuity.

Fixing Techniques

To fix bad connections, follow these steps:

Clean the Connector: Use a wire brush to remove rust.

Tighten Loose Parts: Make sure connectors fit tightly with pliers.

Replace Broken Parts: Swap out damaged wires or connectors.

Preventive Measures

Regular Check Tips

Regular checks stop issues early. Look at connectors every few months for damage, especially in wet areas.

Environmental Factors

Things like humidity and road salt can harm connectors. Use sealed ones in wet places to avoid rust. Apply grease to protect from weather damage.

Maintenance Tips

Cleaning and Care

Keep connectors clean with a soft brush and cleaner. Avoid strong chemicals that might harm them.

Making Them Last Longer

To make connectors last:

Use Good Tools: High-quality tools help make strong connections.

Avoid Too Much Heat: When soldering, use just enough heat.

Cover with Heat Shrink: Protect connections with heat shrink tubing from weather damage.

By following these tips, car electrical systems stay reliable and work smoothly.

Knowing different car connectors is important for car safety and working well. Putting them in right and taking care of them helps them last longer. It's smart to choose good connectors that fit your car. This stops electrical problems and makes the car run better. Buying strong connectors keeps the car's electric parts safe and makes driving smoother and more reliable.

See Also

Understanding HSD Connectors Within Automotive Applications

Benefits of HFM Connectors for Automotive Solutions

Significance of FAKRA Connectors in Automotive Systems