Emerging Trends in Automotive Wiring Connector Types

The car industry needs better wiring solutions now. Cars today are more complex and require various automotive electrical connectors types to function effectively and safely. These connectors enhance vehicle performance and ensure safety. As the demand for different connectors increases, understanding the latest technology becomes crucial. The focus on electric cars, self-driving capabilities, and connectivity highlights the importance of these advancements.

Current Problems in Car Wiring Connectors

Getting Parts

Supply Chain Problems

Car wiring connectors have big problems because of supply chain issues. The COVID-19 pandemic caused lockdowns and money worries, slowing down the market for a while. Makers had trouble getting parts they needed, messing up their schedules. So, companies had to change fast to new situations. They looked for other suppliers and changed plans to keep going. This showed how important it is to have a strong supply chain in the car wiring connectors business.

Effect on Making Cars

Supply chain problems messed up making cars on time. Waiting for parts made building cars take longer. This problem slowed down giving cars to buyers. Makers had to find ways to fix these delays. They worked on bettering their processes and being more efficient. By doing this, they tried to lessen the delay effects and keep customers happy.

Rule Changes

Green Rules

Green rules are very important for car wiring connectors now. Governments everywhere are making stricter pollution rules. These rules push makers to create connectors that help green tech work well. Electric cars (EVs) are a big part of this change now. The fast growth of EVs, especially in North America, means more special connectors are needed. These must handle tough car conditions but still work great.

Safety Rules

Safety rules also shape how car wiring connectors get made now. Self-driving needs strong connectors that send data fast and safe. As self-driving cars become common, secure connections matter more than ever before. Makers must follow safety rules so these connectors stay reliable always. This focus on safety pushes new ideas in making car connectors, leading to better solutions that boost car performance and safety.

New Technology in Car Electrical Connectors

The car world is changing from old to new connectors. This change helps cars work better, last longer, and use less energy.

Change from Old to New Connectors

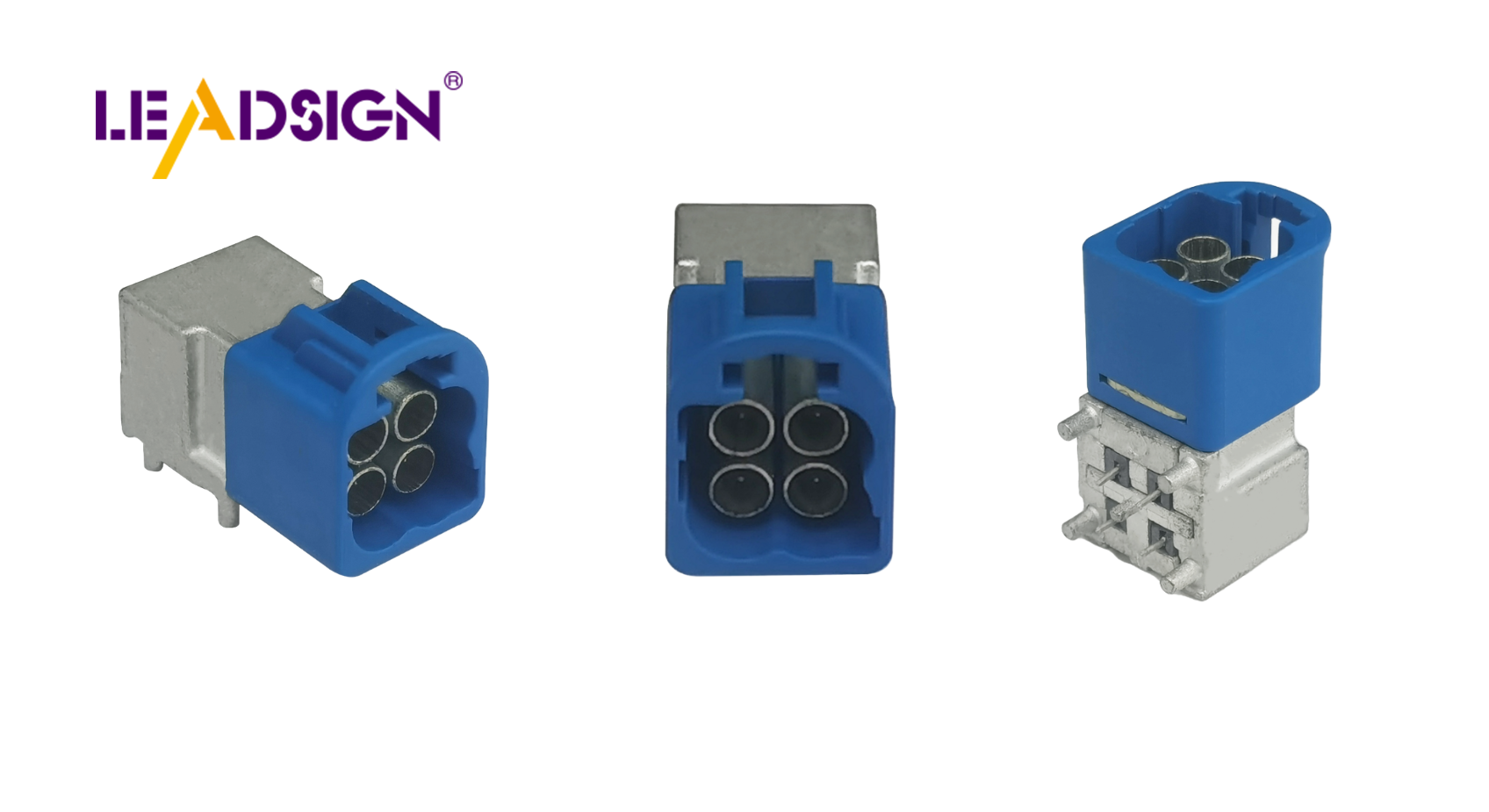

Making Connectors Smaller

New cars need small and smart parts. Tiny connectors help meet this need. They save space and make the car lighter, helping it run better. Small connectors fit more parts in tight spots, which is key for adding cool tech like self-driving systems.

Stronger and More Reliable

Car connectors must handle tough places with heat, shaking, and wetness. New designs and materials make them stronger and more reliable. These keep working well over time, even when things get rough. Smart connectors with sensors check how they’re doing all the time, making sure they stay in good shape.

New Connector Materials

Using Light Materials

Light materials are now important for making connectors. They cut down on car weight, boosting fuel savings and speed. Light connectors also help cars move better, making them great for today’s car designs.

Better Conductivity and Heat Handling

New materials improve how well connectors carry power and handle heat. This means they can send data fast without losing power. Fast data is needed for systems like music players or maps in cars. Good heat handling keeps them working safely even when hot, keeping the car safe too.

Material and Design Innovations for Automotive Connectors show why light, rust-proof connectors matter. These changes are key for making cars work well and be trustworthy.

Real-World Uses and Advantages

Use in Electric and Hybrid Cars

Better Energy Use

Electric and hybrid cars need special wiring connectors. These help save energy. They move power from the battery to car parts without wasting it. This helps cars go farther and charge faster. Light materials in connectors make the car weigh less, saving more energy.

Improved Car Performance

New connectors make electric and hybrid cars work better. They help add smart systems like braking that saves energy. These systems catch and reuse lost energy, making cars perform better overall. Good connectors ensure all electronic parts work well for a smooth drive.

Gains in Self-Driving Car Systems

More Data Sending Power

Self-driving cars need fast data sending to be safe. Advanced connectors send data quickly between sensors, cameras, and controls. This helps the car process lots of info fast, making smart choices quickly. Smiths Interconnect connectors show how new connectors help test cars by handling complex data needs.

Better Safety Features

Safety is key in self-driving systems. Modern connectors make strong connections for safety features like crash avoidance and lane help. These need accurate data to work right, so good connectors are crucial for keeping them reliable. Thus, self-driving cars with advanced connectors keep passengers safer.

The blog talked about changes in car wiring connectors. These parts are very important for new cars. It mentioned moving to smaller and stronger connectors. New materials help them work better too. More special connectors will be needed as cars become electric and self-driving. Future ideas will keep improving these connectors. People in the car business need to know about these changes. This helps them stay ahead and make sure cars are safe and work well.

See Also

Understanding HSD Connectors Within Automotive Applications

Why Fakra Connectors Matter for Today's Vehicles

Significance of Fakra Connectors in Auto Manufacturing