Easy Installation Tips for Automotive Electrical Connectors Types

Correctly installing automotive electrical connectors types is very important. They help your car work well and stay safe. Connectors ensure different parts connect properly, which is essential as cars become more complex. Choosing the right connector for each job is key. Good connectors handle advanced electronics and safety needs. Follow this guide to install them correctly. This ensures your car runs smoothly and safely.

Getting Ready to Install

Before you start putting in automotive electrical connectors, get ready well. This makes the installation easy and quick.

Tools You Need

First, collect these important tools:

Wire strippers and cutters: These help take off wire covers and cut wires. Stripped wires connect better.

Crimping tools: Use a good crimping tool like the MSD Ratcheting Crimp Tool. It makes strong crimps for connectors like Packard 56 and Weatherpack. It crimps both parts at once.

Multimeter for testing: A multimeter checks connections. It shows if they are safe and working right.

Staying Safe

Safety is very important with electrical work:

Disconnecting the battery: Always unplug the car battery first. This stops shocks and keeps the car safe.

Wearing protective gear: Wear safety glasses and gloves. They protect from sparks or sharp wires.

Setting Up Your Space

A neat workspace helps with installation success:

Ensuring a clean and organized area: Keep your area tidy. An organized space helps find tools fast and keeps small parts safe.

Adequate lighting and ventilation: Make sure your space is bright enough to see well, which reduces mistakes. Good air flow is needed if there are fumes.

By getting ready well, you make installing automotive electrical connectors easier. Good preparation makes it smoother, safer, and more reliable for your car's systems.

Understanding Automotive Electrical Connectors Types

Knowing about automotive electrical connectors types is important. Each type has a special job to help your car's electric system work well.

Blade Connectors

Blade connectors are very common in cars. They are easy to use and dependable.

Uses and Applications

Automotive Wiring Harnesses: Blade connectors link different car parts together.

Fuse Boxes: They fit well in fuse boxes and handle lots of electricity.

Advantages and Limitations

Advantages:

Simple to plug in and take out, so they're easy to use.

Stay connected even if the car shakes.

Limitations:

Not good for wet places unless sealed tight.

Might need extra covering to stop short circuits.

Bullet Connectors

Bullet connectors are also popular. They join wires simply and effectively.

Uses and Applications

Lighting Systems: Used in lights like headlights.

Speaker Connections: Connect speakers in audio systems reliably.

Advantages and Limitations

Advantages:

Fast to put on, saving time.

Small size fits tight spaces well.

Limitations:

Can loosen if not crimped right.

Carry less electricity than other types.

Butt Connectors

Butt connectors join two wires end-to-end securely in cars.

Uses and Applications

Wire Repair: Great for fixing or extending wires.

Splicing Wires: Join wires together for a continuous path.

Advantages and Limitations

Advantages:

Strong connection that won't shake loose.

Heat-shrink versions protect from water damage.

Limitations:

Need proper tools for secure connection.

Hard to disconnect once crimped, which can be tricky if changes are needed often.

Knowing these connector types helps you pick the right one. Each has its pros and cons, so choose wisely for your car's needs. This keeps your vehicle's electric system working well.

Step-by-Step Installation Guide

Getting the Wires Ready

To install well, wires must be ready. This step is key for a safe and good connection.

Cutting to the Right Length

Measure the Wire: Use a ruler to find how long it should be. Make sure it's long enough to reach without pulling.

Cut the Wire: Use wire cutters to cut it right. A clean cut stops fraying and looks neat.

Taking Off Insulation

Pick the Right Tool: Choose a wire stripper that fits your wire size. This stops damage.

Remove Insulation: Take off about half an inch of cover from the end. Show enough wire for a strong connection but not too much bare wire.

Crimping Connectors

Crimping is important to attach connectors to wires well. Good crimping makes sure electricity flows right.

Picking the Right Crimping Tool

Choose the Tool: Pick one that works with your connector type, like a ratcheting crimp tool for Packard 56.

Check Tool's Shape: Make sure it's working well. A good tool gives even crimps.

Making Sure Crimp Holds Tight

Put in Connector: Push stripped wire into connector fully.

Crimp Connector: Squeeze handles hard so it's tight and won't slip out.

Keeping Connection Safe

After crimping, protect it from outside things.

Using Heat Shrink Tubing

Pick Tubing: Get tubing that fits over connector, slightly bigger than it.

Put on Tubing: Slide tubing over connection and use heat gun to shrink it tight around connector.

Checking Connection with Multimeter

Set Up Multimeter: Turn on multimeter, set it for resistance or continuity check.

Test Connection: Put probes on each side of connection; low resistance means it's good.

Follow these steps for strong automotive electrical connections that last long and work well, boosting car safety and performance.

Fixing Common Problems

Even if you install carefully, problems can happen with automotive electrical connectors. Knowing these issues and fixing them keeps your car's electric system working well.

Bad Connection

A bad connection might cause flickering lights or stop parts from working. Finding and fixing loose crimps is important.

Finding Loose Crimps

Look Closely: Check the crimped connectors. Loose ones look uneven or not tight.

Pull Test: Gently pull the wire. If it slips out, the crimp is loose.

How to Re-crimp

Take Off Connector: Carefully remove the connector from the wire.

Strip Wire Again: Strip a new part of the wire for a clean crimp.

Pick Right Tool: Use a tool that fits your connector type and is in good shape.

Crimp Hard: Put wire in connector and press hard with tool. It should hold tight and not slip out.

Electric Failures

Electric failures can come from rust or wrong wire size. Fixing these helps keep electricity flowing well.

Checking Rust

Check Connectors: Look for rust or color changes on connectors; rust blocks electricity.

Clean Rusty Parts: Use a brush or cleaner to remove rust; dry before putting back together.

Right Wire Size

Check Wire Size: Make sure wire size matches what connector needs; right wire size can overheat or not power enough.

Change Wrong Wires: If size is wrong, switch to right one for good power flow.

Tip: Factory-made connectors are often better than homemade ones because they are made in controlled settings, reducing risks of big problems.

Fixing these common problems makes your car's electrical connections more reliable. Regular checks help avoid future issues, keeping your car's electric system running smoothly.

Knowing how to install car electrical connectors is important. Follow the steps to make sure connections are safe and strong. Check them often to stop problems later, keeping your car's electric system working well. Be gentle with connectors to keep them clean and last longer. Share your stories and advice in the comments. Your ideas can help others install better and keep their cars running well.

See Also

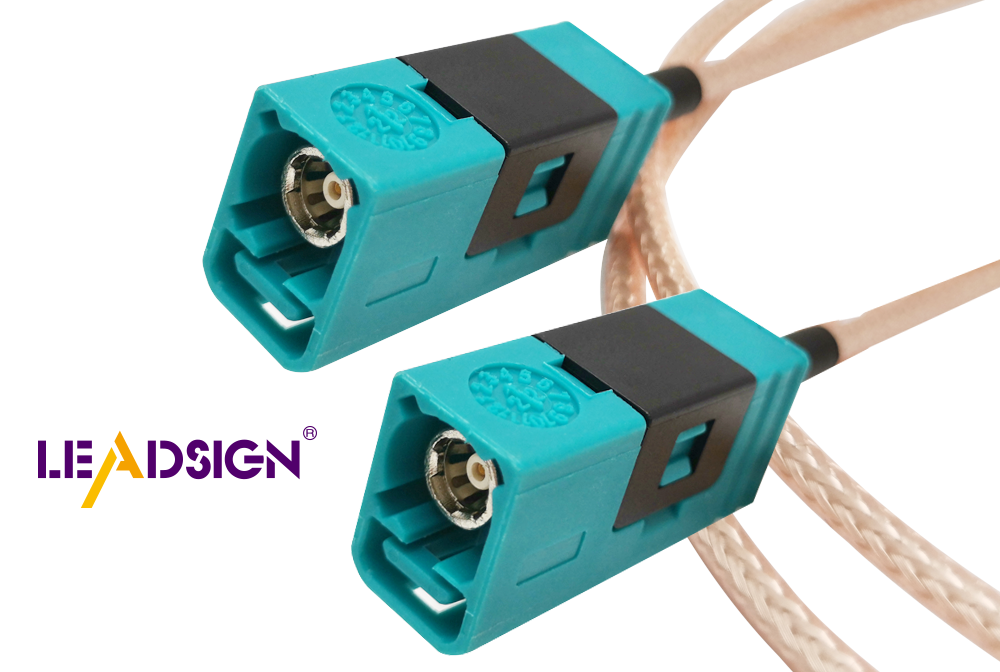

Understanding HSD Connectors For Automotive Applications

Significance of FAKRA Connectors in Vehicle Systems

Benefits of FAKRA PCB Connectors for Automotive Use