Copper vs Aluminum: Choosing the Right Wire for 2 Pin Automotive Connectors

Choosing the right car wiring wire for car connectors is crucial. It ensures your vehicle operates efficiently and safely. You can opt for either copper or aluminum wires. Copper excels at conducting electricity, making it a strong and reliable choice for car wiring. Additionally, copper experiences less expansion with heat, enhancing safety. On the other hand, aluminum is lighter and more cost-effective, which can be beneficial when weight is a concern. Understanding these factors will assist you in selecting the best wire for your car.

Key Takeaways

Copper wires are superior in conductivity, making them ideal for high-performance automotive applications where reliable power delivery is crucial.

Aluminum wires are lighter and more cost-effective, suitable for applications where weight reduction is a priority, but they require careful installation to ensure safety.

Durability is a significant factor; copper wires are stronger and resist rust, leading to longer-lasting connections compared to aluminum.

Thermal expansion affects wire performance; copper expands less with heat, maintaining tight connections and reducing the risk of overheating.

While copper has a higher upfront cost, it can save money in the long run by minimizing repair needs due to its durability and reliability.

For safety and performance, copper is generally the best choice for critical car components, while aluminum can be used for less critical parts where weight and cost are more important.

Always consider the specific needs of your vehicle when choosing between copper and aluminum, ensuring proper installation to maximize safety and efficiency.

Comparing Car Wiring Wire: Copper vs Aluminum

Conductivity of Copper Conductors vs Aluminum Conductors

When picking car wires, think about conductivity. Copper carries electricity better than aluminum. This means copper wires let more electricity flow easily. Copper's high conductivity helps cars work well. But aluminum wires are cheaper. They don't conduct as well but are lighter. This can help make cars weigh less.

Durability and Tensile Strength of Copper and Aluminum

Durability is key for car wires. Copper wires are strong and last long. They handle stress better than aluminum wires. Copper doesn't break easily. Its strength keeps it safe in tough spots. Aluminum wires are softer and can break. They might not connect well and could fail. Aluminum is light but can rust. Copper doesn't rust much, so it's better for long use.

Thermal Expansion in Copper and Aluminum Wires

Heat makes wires expand. Copper wires expand less than aluminum ones. This means copper stays tight when hot. Aluminum expands more with heat. This can cause loose wires and rust. Installing them right helps avoid problems. Even though aluminum is light and cheap, copper stays stable in heat. That's why many choose copper for cars.

When picking between copper and aluminum wires, think about cost. Copper wiring costs more than aluminum wiring. This is because copper is better at carrying electricity and lasts longer. You might pay more for copper at first. But it can save money later. Copper doesn't rust easily and keeps strong connections, reducing repair costs.

Aluminum wiring is lighter and cheaper to start with. This is good if you want to spend less. But aluminum doesn't carry electricity as well. You might need bigger wires for the same power as copper. This can make it less cheap. Also, aluminum rusts more, which can mean more repairs later.

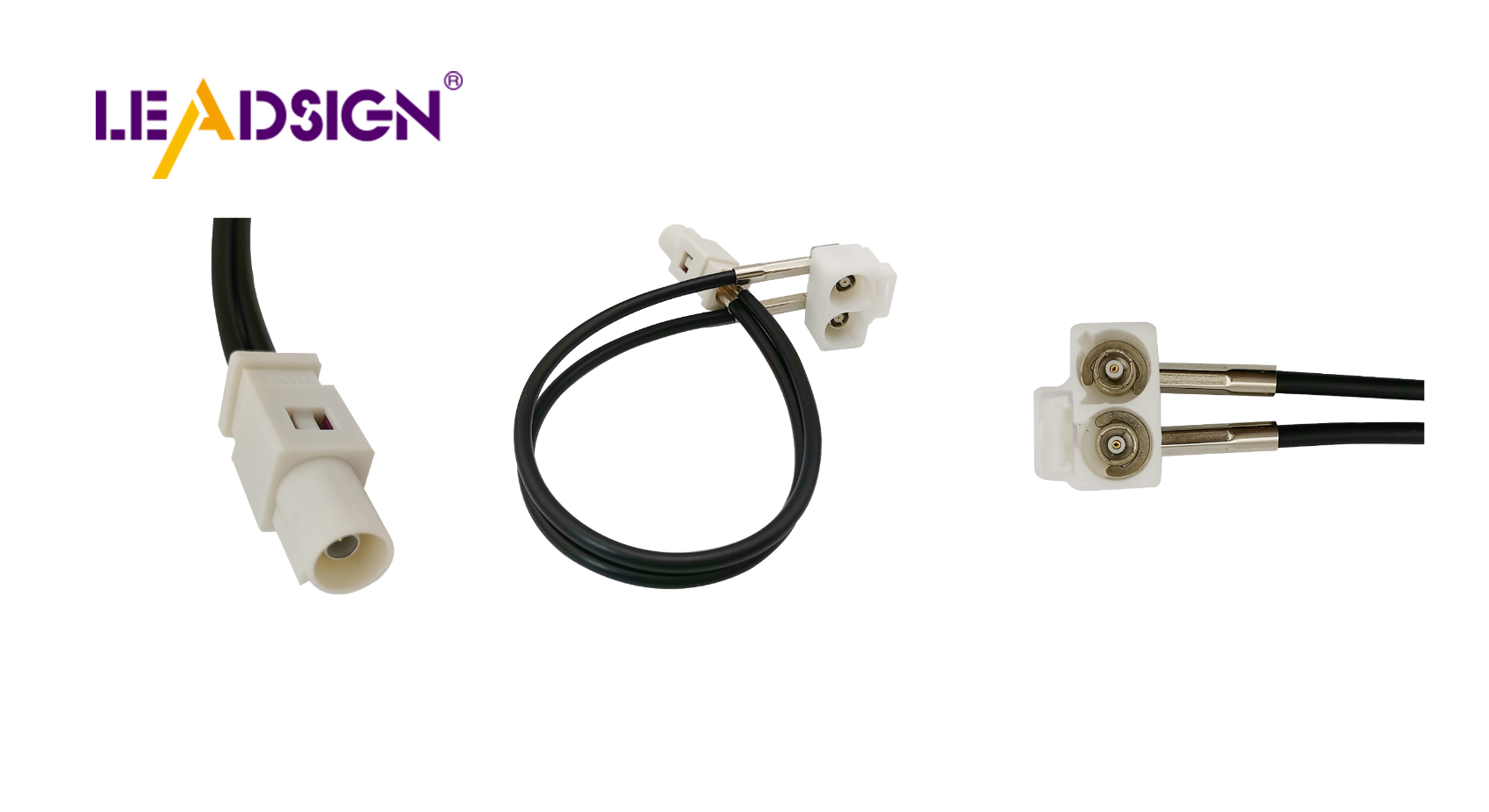

Specific Needs for 2 Pin Car Connectors

Safety and Fit with Copper and Aluminum Wires

When picking wires for 2 pin car connectors, safety and fit are key. Copper wires are safer because they carry electricity well and are strong. They keep tight connections, lowering the chance of overheating and fires. Copper doesn't rust much, so it's safe for a long time, making it a good pick for cars.

But aluminum wires are lighter and cheaper. They need careful setup to stop loose connections and rust. Aluminum changes size with heat, which can be unsafe if not watched. So, while you can use aluminum, it needs more care to stay safe and fit.

Best Use for Copper and Aluminum in Car Connectors

The best use of copper and aluminum in car connectors depends on what you need. Copper wiring is great for high-performance places where you need it to work well and be steady. It carries power well, so it's good for important car parts.

Aluminum wiring is lighter, so it's good when you want to make the car lighter. It's a cheap choice for less important parts where you don't need as much power. But you might need bigger wires to match copper's power, which can change space and design plans.

Picking between copper and aluminum wires for car connectors needs thought.

Copper wires are better at carrying electricity and are strong. They handle lots of electricity without getting too hot. This makes them great for important car parts. Copper stays strong for a long time.

Aluminum wires are lighter and cheaper. They are good when you need to make the car lighter. But they need to be put in carefully to work well.

For most car needs, copper is the best choice because it works well and is safe. Knowing these differences helps you choose the right wire for your car.

FAQ

Why is copper better for car wires?

Copper carries electricity well. It stops wires from getting too hot. This keeps cars safe from fires. Copper also doesn't rust easily, so it lasts long.

Why use aluminum in cars?

Aluminum is light and cheap. It's good when cars need to be lighter. But it must be put in right to stop loose wires.

Is copper stronger than aluminum?

Yes, copper is stronger. It doesn't break easily. This makes it good for car parts that need to last.

Is copper wiring safer than aluminum?

Yes, copper is safer. It carries electricity well and doesn't rust much. This makes it less likely to cause fires.

Can aluminum wires be safe in cars?

Yes, if put in right. Tight connections are important. Aluminum can rust, so check it often.

How do copper and aluminum costs compare?

Copper costs more at first. But it saves money later by needing fewer repairs. Aluminum is cheaper but might need bigger wires.

How does heat affect copper and aluminum?

Copper doesn't change size much with heat. This keeps wires tight. Aluminum changes more, so it needs careful setup.

Which wire is best for high-performance cars?

Copper is best. It works well under tough conditions. It handles lots of electricity without getting too hot.

When is aluminum better?

Use aluminum when weight matters more than power. It's good for parts that don't need much electricity.

How to choose between copper and aluminum?

Think about what your car needs. For safety and power, pick copper. For less weight and cost, pick aluminum. Always install them right.

See Also

Enhancing Vehicle Data Flow With Superior Connectors And Cables

Benefits of HSD Connectors for Automotive Applications

Key Benefits of HFM Connectors in Automotive Technology