A Step-by-Step Guide to Choosing Automotive Electrical Connector Plugs

Car connector plugs are important for your car's electrical system. They help move power safely and efficiently. Picking the right plug can be hard. You need to think about power needs, water resistance, and cable fit. Also, check the environment and match it with OEM systems for best performance.

Key Takeaways

Pick the right car connector by knowing your car's power needs. Make sure it fits well to avoid loose wires.

Think about the environment when choosing connectors. Use waterproof ones in wet or dirty places for better performance.

Choose OEM connectors to match your car's original parts. They work well and lower the chance of electrical problems.

What Are Car Electrical Connectors?

Definition and Purpose

Car electrical connectors join wires in your car's system. They make sure power and signals move safely and reliably. These connectors come in different types for specific uses. Pin or pigtail connectors link wires to circuits. Blade connectors attach wires to terminals. Bullet connectors allow quick and easy connections.

Type of Connector | Description |

|---|---|

Pin/pigtail connectors | Connect wires directly to a circuit. |

Blade connectors | Attach wires to a terminal. |

Bullet connectors | Allow fast connections and disconnections. |

Picking the right connector keeps your car's system safe and efficient.

Importance in Vehicle Electrical Systems

Car connectors are key to your car's performance. They link wires and keep circuits working well. These connectors also help systems like the engine and sensors communicate. Locking parts stop wires from coming loose. Proper use prevents bad connections.

Without connectors, your car's electrical system won't work. They keep power and data flowing so systems work together. From simple wiring to advanced data connectors, they are very important.

Knowing about these connectors helps you fix or improve your car's system.

Types of Auto Electrical Connectors

Blade Connectors

Blade connectors are very common in cars. You install them by sliding the blade into a terminal. They hold wires tightly, stopping accidental disconnections. These connectors are great for low-power uses like lights or small gadgets. But, they can loosen if not checked often. Their simple design makes them a favorite for many car systems.

Pin Connectors

Pin connectors are flexible and used in many car systems. They have a pin-and-socket design for strong power or signal links. You’ll see them in engines or sensor setups. Their small size fits tight spaces, perfect for modern cars. Pin connectors help keep your car’s electrical system working well.

Weatherproof Connectors

Weatherproof connectors handle tough conditions like heat, water, and dirt. They use materials like rubber to block moisture and grime. These connectors are great for under-hood areas with lots of vibration. They last long and work well in harsh environments. If you need strong outdoor connectors, these are a smart pick.

Multi-pin Connectors

Multi-pin connectors join many wires in one unit. They are perfect for complex systems like screens or safety tools. These connectors save space and make wiring easier. Their locks stop wires from coming loose, keeping things stable. Multi-pin connectors are key for modern cars with advanced systems.

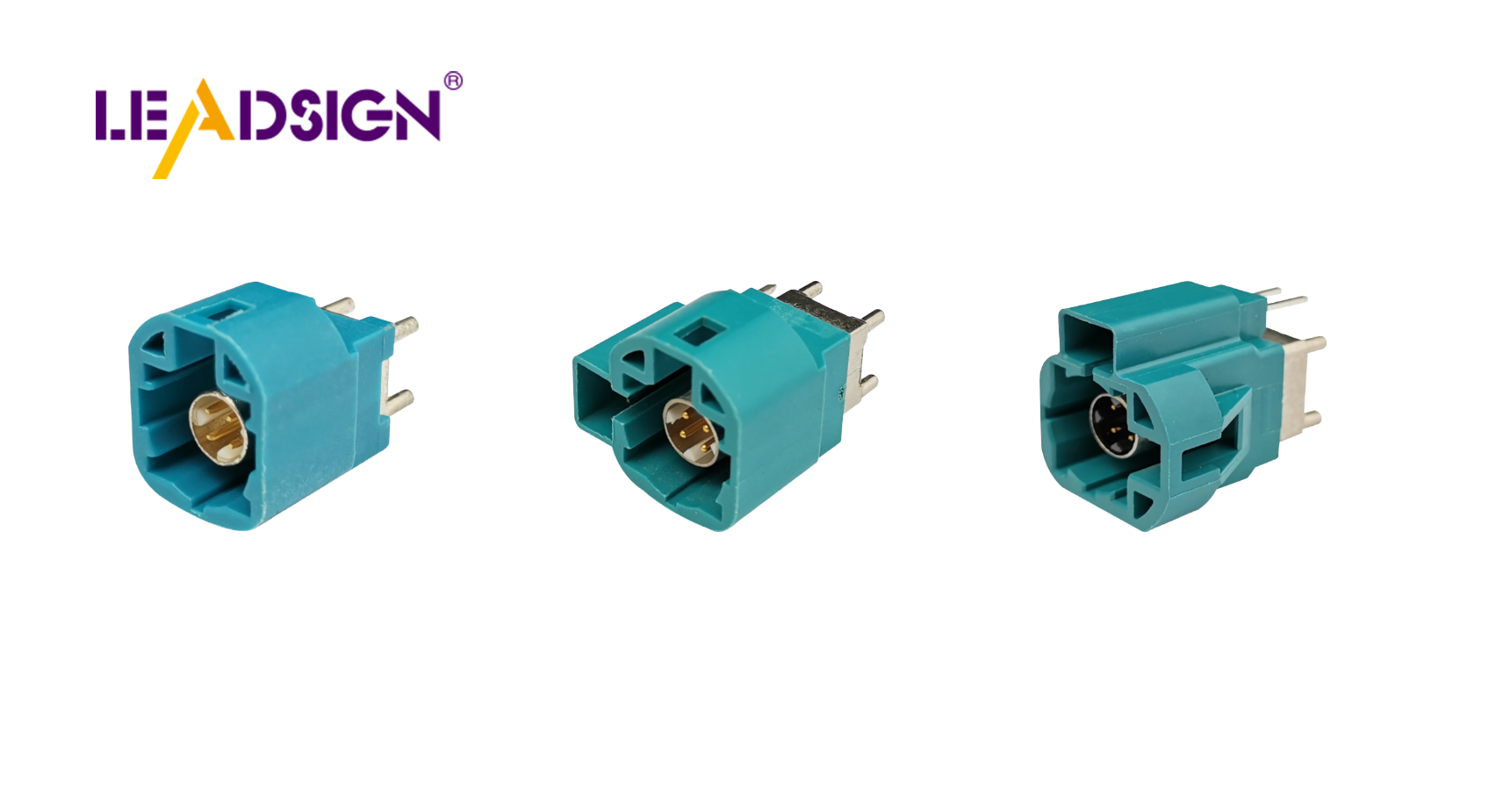

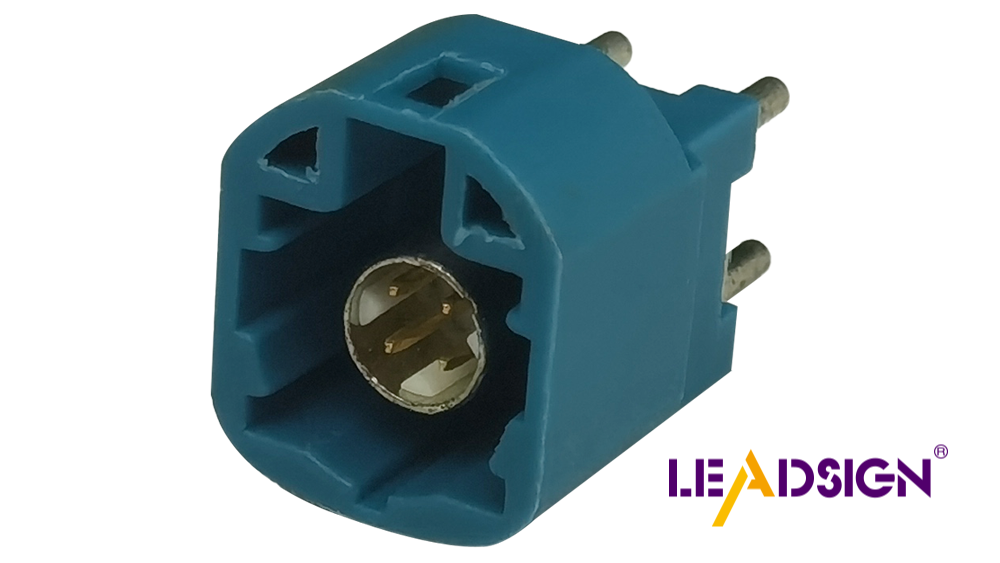

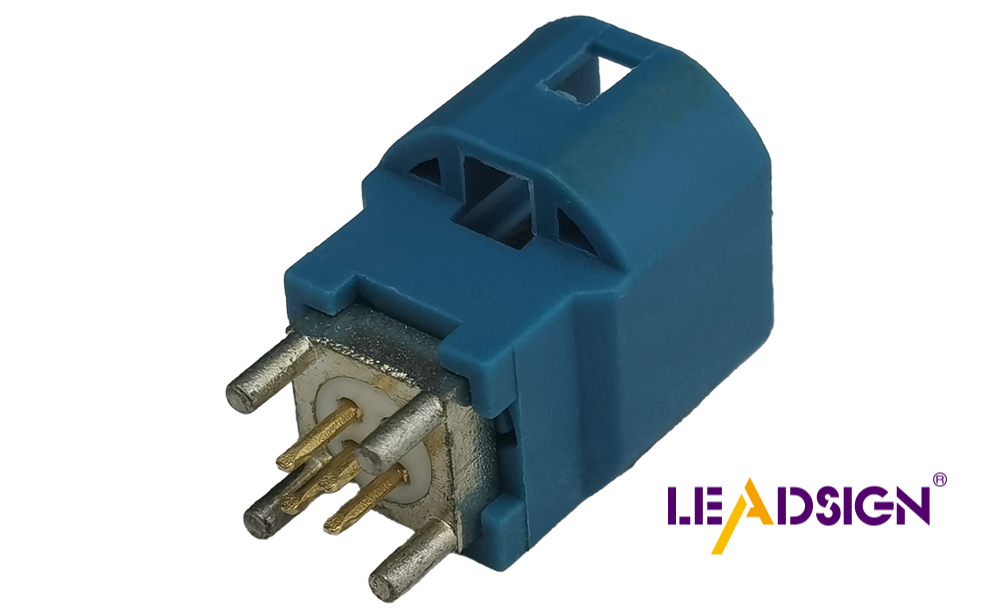

Specialty Connectors (e.g., HSD Connectors for High-Speed Data Transmission)

Specialty connectors, like HSD connectors, are for high-tech car features. HSD connectors send data quickly, useful for cameras or screens. They have locks to keep wires secure and prevent mismatches. These connectors are important for cars with digital systems and smart features.

How to Pick the Best Car Connector Plug

Understand Your Car's Electrical Needs

First, learn what your car's electrical system needs. Check the power and voltage levels for the connector plug. Make sure the connectors lock tightly to stop loose wires. Look at how wires connect, like crimping or soldering, as it affects signals. Match the connector size to the wire thickness to avoid problems. Also, see if the connectors follow rules like ISO or SAE for safety.

Think About Environmental Factors (e.g., heat, water, shaking)

The environment affects how well connectors work. Water can cause rust, making them less effective. Heat might melt parts or damage connectors. Pick connectors that handle your car's conditions. For wet or dirty areas, use weatherproof connectors. If connectors are near the engine, choose ones tested for shaking and vibrations.

Check Material Strength and Quality

The material of connectors matters for how long they last. Plastic connectors are light and good for most car wiring. Metal connectors are stronger and better for heavy-duty jobs. High-quality materials like nylon or PBT resist car fluids and tough conditions. Always pick certified connectors for better performance.

Today's car connectors can handle heat, shaking, and interference, making them reliable in all conditions.

Match with OEM Systems

OEM connectors fit perfectly with your car's original parts. They meet strict standards, lowering the chance of electrical issues. Using OEM connectors keeps your car's system working well during fixes or upgrades.

Look for Easy Installation and Care

Choose connectors that are simple to install and maintain. Plug-and-play designs save time and reduce mistakes. Check for easy locking and low force needed to connect. Good connectors lose less signal and keep a strong connection. Regular checks and care will make them last longer and work better.

Installation and Maintenance Tips for OEM Automotive Connectors

Getting Ready for Installation

Prepare well to install OEM connectors easily. Clean all parts to remove dirt. Use tools like wire strippers and crimpers for neat connections. Don’t use connectors that are too big or small for wires. Follow these steps for the best results:

Strip wire insulation with a wire stripper.

Add a seal to block moisture and dust.

Secure terminals into connectors tightly.

Take your time to avoid mistakes and ensure a good fit.

Correct Connection Methods

Using proper methods is very important. Line up connectors carefully to avoid bending pins. Press firmly to connect them tightly. Use dielectric grease to protect from water and rust. Always check that connectors lock in place to stop loose wires.

Regular Care and Checks

Check connectors often to keep them working well. Look for rust, dirt, or damage. Clean them with air or a soft brush. Add a little dielectric grease to keep out water. Replace broken connectors right away to keep things running smoothly.

Maintenance Task | Purpose |

|---|---|

Check for Damage | Spot rust, dirt, or loose parts. |

Clean Connectors | Remove dirt and stop rust. |

Use Grease | Keep out water and make them last longer. |

Fixing Common Problems

Common issues include rust, loose wires, and overheating. Regular checks help find problems early. Clean rusty or dirty connectors well. For loose wires, check locks and alignment. Use a multimeter to test connections and replace bad parts quickly. Be gentle during installation to avoid breaking pins or parts.

Tip: Keep connectors safe from heat and shaking to make them last longer.

Picking the right car electrical connectors keeps your car safe. Think about OEM fit, strength, and easy setup. Good connectors stop problems, handle tough conditions, and need less fixing. Smart choices protect important parts and keep your car running well.

Tip: Use OEM connectors for strong and dependable car electrical systems.

FAQ

How are OEM connectors different from aftermarket ones?

OEM connectors fit your car's original parts exactly. They are reliable and work well. Aftermarket connectors might not fit as well, causing problems.

How can I tell if a connector is weatherproof?

Check for seals or gaskets on the connector. These stop water and dirt. Look for words like "IP-rated" or "weather-resistant" in the description.

Is it safe to reuse old connectors for repairs?

Reusing old connectors can be unsafe. They might be worn or damaged, leading to issues. Always check them carefully or replace them for better results.

Tip: Keep extra connectors ready for quick fixes when needed.

See Also

A Comprehensive Overview of Ford Fakra Connectors

In-Depth Insights Into the Fakra Plug Explained

Uncovering Advantages of Fakra Connectors in Vehicles