What to Look for in Custom Automotive Wiring Harness Solutions

Choosing the right car harness connectors is very important. They help your car work well and stay safe. Good wiring connectors keep electricity flowing and signals strong. This makes sure safety features like airbags and ABS work right. Strong connectors also lower the chance of problems, keeping everyone safe and the car running better.

Car harness connectors link different systems in your car. They help safety tools, music systems, and maps work smoothly. Picking strong and good connectors means they last longer. It also lowers the risk of electrical issues.

Key Takeaways

Pick good-quality car harness connectors for safety and performance. Strong connectors help systems work well and prevent problems.

Learn your car's exact electrical needs. Think about voltage and weather conditions when choosing connectors.

Choose connectors with tough materials. Plastic is light for daily use, while metal is stronger for tough jobs.

Identifying Vehicle-Specific Needs

Understanding Electrical System Needs

Knowing your car's electrical system is very important. Modern cars use complex systems to power parts and give updates. Gas-powered cars have a starter, battery, and alternator. Electric cars use a big battery to run and move.

Here are some electrical needs to think about:

Powering things like windows, radios, and sensors.

Handling higher voltages in electric cars (300-800 volts) than gas cars (12 volts).

Using connectors that match the right voltage and power levels.

By checking these needs, you can pick the best connectors for your car.

Environmental Factors for Car Connectors

The environment affects how well car connectors work. Make sure they can handle tough conditions.

Factor | What It Means |

|---|---|

Heat Resistance | Materials must handle high heat from the car. |

Water Resistance | Stops water from causing rust or short circuits. |

For hot areas, use connectors that resist heat. In wet places, pick water-resistant ones to avoid damage. Strong connectors also last longer by resisting wear and rust.

Choosing Connectors for Your Car's Design

Your car's design decides what connectors you need. Some connectors are made for special uses. For example:

Small round connectors fit tight spaces like engine areas.

Bayonet connectors are great for tough conditions because they seal well.

Rectangle connectors are used for engine systems like fuel and ignition.

Choosing the right connectors helps your car work better. Whether for lights, music, or the engine, good connectors improve performance.

Evaluating Material and Build Quality

Why Strong Materials Matter for Wiring Connectors

Strong materials make connectors last longer and work better. They can handle tough use without breaking. Plastic connectors are light and strong, good for most cars. Metal connectors are tougher and protect better. They are best for big machines like tractors or trucks.

Think about your car's needs when picking materials. Plastic is great if you want a lighter car. Metal works well in rough places and gives more protection.

Comparing Materials for Car Connector Systems

Different materials have their own benefits. Here's a simple guide:

Material | Benefits | Best Use |

|---|---|---|

Plastic | Light, strong, lasts long | Regular car use |

Metal | Tough, protects better | Heavy-duty machines |

Plastic connectors help make cars lighter. Metal ones are better for tough jobs. They also block electric interference, keeping systems working well.

How to Spot Bad Build Quality

Finding bad connectors early can stop future problems. Check for cracks, rough edges, or loose parts. These show weak materials or bad design. Good connectors should feel strong and fit tightly.

If your car has electric issues, check the connectors. Replacing bad ones with better-quality connectors can make your car safer and work better.

Understanding Connector Types and Compatibility

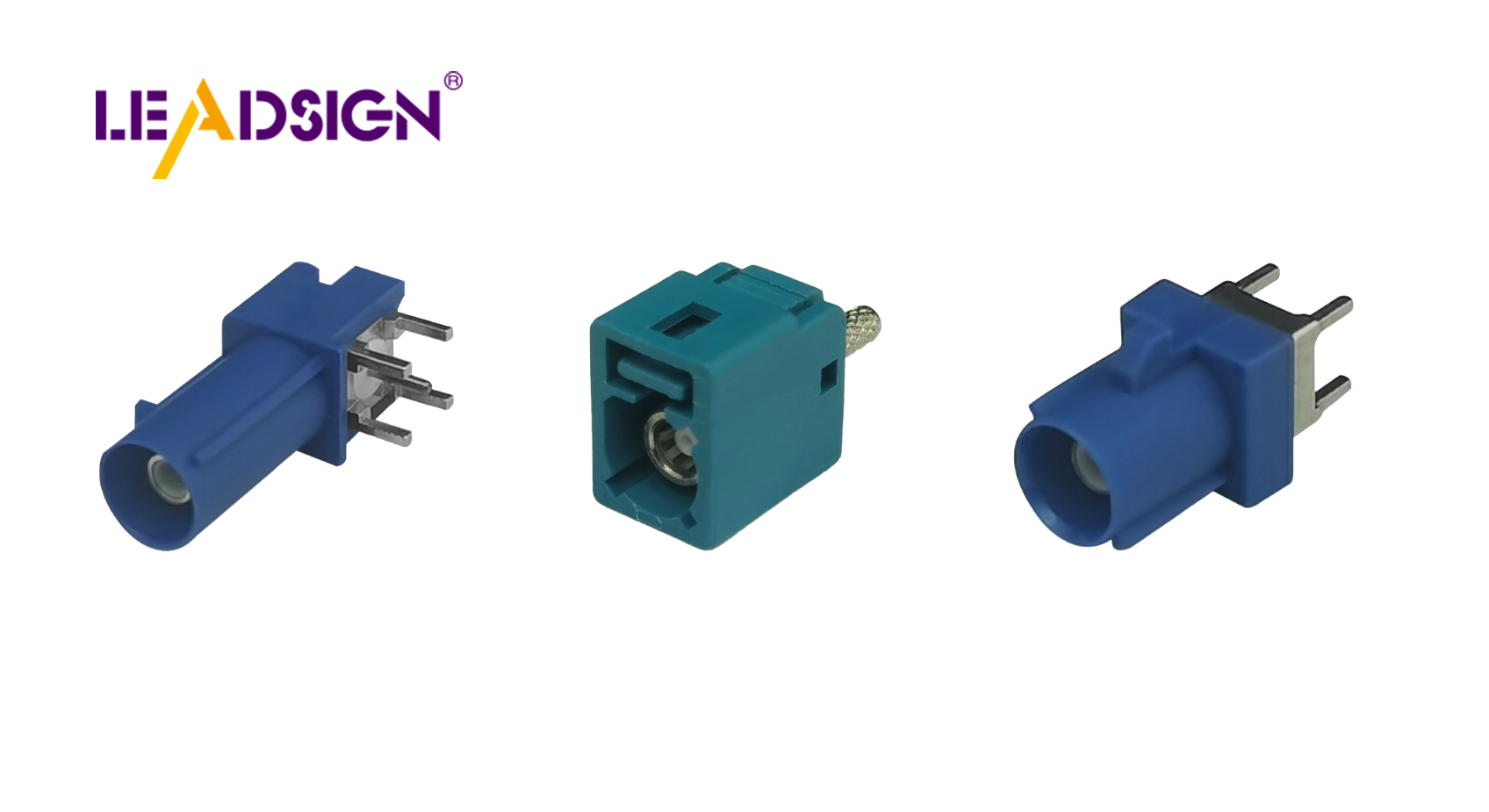

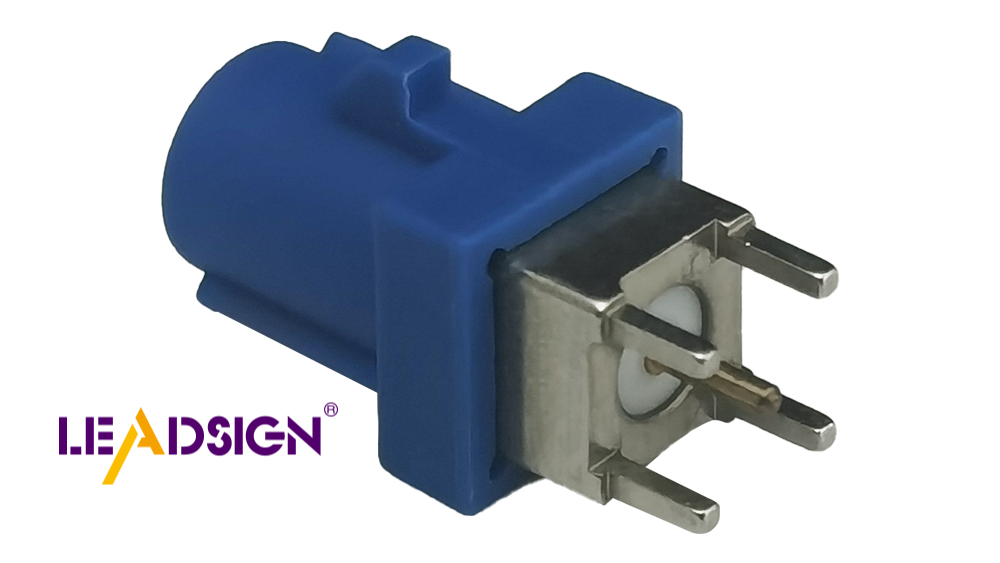

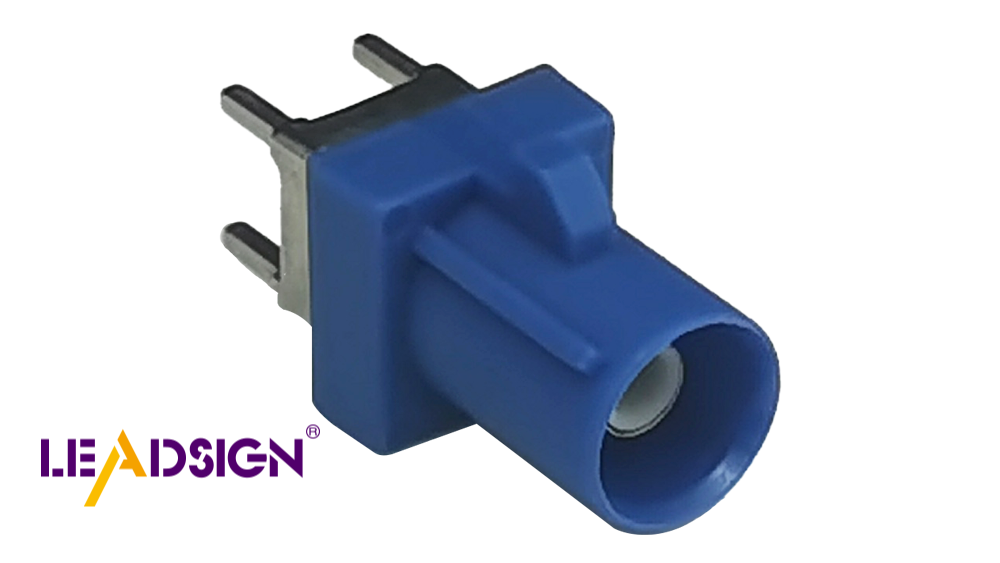

Common Types of Car Harness Connectors

There are many types of connectors in car wiring. Each type has a special job to keep things working. Here are some common ones:

Pigtail connectors: Connect wires to parts like lights or sensors.

Terminal blocks: Group many wires in one place neatly.

Bullet connectors: Easy to connect and disconnect quickly.

Scotch Locks: Join wires without needing to cut them.

Some factory connectors are made for specific uses. For example:

Connector Name | Type | Common Uses |

|---|---|---|

2-pin | Fog lights, Headlights | |

R62C8 | 8-pin | Radar, Blind Spot, Pedal Sensors |

B85C3 | 3-pin | Turn Signals, Headlights |

You may also see special harnesses like GPS antenna harnesses. Electric cars use high-power connectors for tough jobs. These connectors work well even in hard conditions.

Ensuring Compatibility with Automotive Connector Systems

Matching connectors is very important for them to work right. Wrong connectors can cause electrical problems. To avoid this, you should:

Check pin positions to make sure they line up.

Look at terminal pairs to avoid loose fits.

Confirm the connector's shape and direction match.

Use tools to check if they meet industry rules.

Smart software can also help plan wire paths better. This reduces problems and keeps your car's wiring safe and efficient.

Testing and Verifying Connector Fit

Testing makes sure connectors work well and last long. Here are ways to test them:

High Voltage Testing: Checks if they handle strong electricity.

Insertion and Withdrawal Testing: Measures how easy they connect or disconnect.

Durability Testing: Tests how they hold up after many uses.

Temperature Cycling: Checks if they work in hot and cold weather.

Vibration Testing: Makes sure they stay strong during shaking.

These tests find weak spots and ensure connectors meet standards. Good connectors make cars safer and last longer.

Thinking About Safety and Following Rules

Rules for Good Wiring Harnesses

Make sure your wiring harness follows important rules. These rules make sure the materials and design are safe for cars. Some common UL rules are:

UL 4: For strong, armored cables.

UL 13: For low-power circuit cables.

UL 44: For wires with heat-safe plastic covers.

UL 62: For bendable cords and cables.

UL 83: For wires with tough plastic covers.

UL 1063 and UL 1072: For machine wires and power cables.

Materials must also follow the law. For example, battery cables need thick wires to handle strong power. Copper is often used, but aluminum is lighter and cheaper.

Fire Safety and Strong Covers

Fire safety and good covers are very important. Wires and connectors must handle heat without melting or burning. Covers stop sparks and fires by keeping wires safe. Look for materials tested to handle heat and last long. For example, plastic covers work well in most cars because they resist heat and damage. Picking the right materials keeps your wiring safe in tough conditions.

Installing Wiring the Right Way

Installing wiring correctly is key for safety and performance. Bad installation can cause loose wires, sparks, or system problems. Always make sure connectors fit tightly and wires are secure. Avoid sharp turns or spots where wires might rub on metal. Test the wires after installing them to check if they work. Good installation helps your car run safely and smoothly.

Assessing Customization Options and Future Expandability

Why Custom Automotive Connector Systems Are Useful

Custom automotive connector systems bring many benefits to your car. They are made to fit your car's exact needs. This makes them more flexible and easier to use. Custom connectors work better with your car's electrical parts. They also allow for new designs and better features.

Tip: Custom connectors save space and make cars lighter. This helps meet fuel-saving goals.

Modern cars need small, light, and efficient parts. Custom systems make connectors smaller and lighter but still strong. They are tough enough to handle hard conditions without breaking or failing.

Preparing for Future Changes and Upgrades

Think about future upgrades when choosing a wiring harness. Lighter harnesses help cars go faster and use less fuel. Aluminum is a popular material because it’s light, but copper is still great for carrying electricity.

Your harness should last through heat, shaking, and wet conditions. A good design makes wires easy to install and fix later. Labeling wires also saves time during repairs.

Note: Safety is very important. Protecting wires prevents problems like short circuits.

Making Customization Affordable

Customizing while saving money takes smart planning. First, figure out what your car needs and your budget. Picking the right materials is key. Copper works well, but aluminum is cheaper and lighter.

A simple design uses fewer materials and costs less. Using standard parts and modular designs makes building easier and cheaper. Working with suppliers can also help you save money without losing quality.

Tip: Think about the total cost over time. Spending more on good materials now can save money on repairs later.

Testing your connectors ensures they work well and last long. This lowers the chance of fixing mistakes later. By following these steps, you can customize your wiring without spending too much.

Tips for Finding Trustworthy Manufacturers

Checking Manufacturer Reputation and Reviews

Start by learning about the manufacturer's reputation. Read reviews from other buyers to see if they make good products. Positive reviews mean they likely offer quality and good service. You can also ask for references from past customers. This shows how they handle orders and fix problems. A good reputation means they care about quality and happy customers.

Look at how long the manufacturer has been in business. Experienced companies usually have better systems and reliable products. They also understand your needs and can offer better solutions for your car.

Questions to Ask About Car Harness Connectors

Asking smart questions helps you pick the right connectors. Use this table to guide your talk with manufacturers:

Aspect | Details |

|---|---|

Dielectric Strength | Can the connectors handle the needed voltage safely? |

Temperature Resistance | Will the materials survive high heat during use? |

Water Resistance | Are the connectors made to block water? |

Material Selection | What materials are used for the parts? |

Production Process | How are the connectors made and tested? |

Quality Control | What checks ensure the connectors are always good? |

These questions help you know if the connectors are strong and reliable. They also show if the manufacturer follows strict quality rules.

Why Warranty and After-Sales Support Matter

A warranty proves the manufacturer trusts their product. Always read the warranty details before buying. A longer warranty often means the connectors are durable. After-sales support is just as important. Good manufacturers help if you have issues later. This includes fixing parts, replacements, or technical help.

For aftermarket connectors, good support keeps your car working well. It also gives you confidence knowing help is available if needed.

Tip: Pick manufacturers with clear warranties and helpful customer service. This ensures a better experience and long-lasting connectors.

Picking the right wiring harness keeps your car safe and working well. Think about your car's needs, strong materials, and proper fit. Experts can help you find good manufacturers and connectors that follow rules. Good wiring harnesses last long and adjust to changes, making them worth it.

Choose quality first. A good wiring harness cuts repairs and boosts performance.

FAQ

Why are custom wiring harnesses better than regular ones?

Custom harnesses are made to match your car perfectly. They boost how well your car works, save room, and allow upgrades later. Regular harnesses don’t offer this level of fit or flexibility.

How can I tell if a connector is strong?

Look for tough materials like metal or heat-safe plastic. Check for certifications and test results, such as vibration or heat tests.

Is it okay to install a wiring harness myself?

You can try, but experts do it more safely and correctly. They check connections and avoid mistakes that might cause problems.

Tip: If unsure, always ask a professional for help with installation.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Why HSD Connectors Are Essential for Automotive Applications

Boosting Data Transfer With High-Speed Automotive Connectors

Key Benefits of HFM Connectors for Automotive Systems

Significance of Fakra Connectors in Modern Automotive Design