Step-by-Step Guide for Car Wiring Wire Installation

Correct car wiring wire keeps your car safe and working well. Bad wiring can cause problems and be dangerous for passengers. Following clear steps helps avoid mistakes and makes the system reliable. Tools like multimeters and checking wires by sight find problems early. A guide helps you do the job confidently and correctly. This way, every car wiring wire connection is strong and works well. It saves time and makes your car work better overall.

Key Takeaways

Proper tools like wire strippers, crimping tools, and multimeters are essential for efficient and safe car wiring installation.

Choosing high-quality materials, such as automotive wires and reliable connectors, ensures a durable and effective electrical system.

Always prioritize safety by disconnecting the battery, wearing protective gear, and working in well-ventilated areas.

Understanding wiring diagrams is crucial; start by identifying power sources and ground connections to simplify the installation process.

Securely routing and labeling wires prevents damage and makes future repairs easier, enhancing the overall reliability of your car's electrical system.

Regularly testing the electrical system with a multimeter helps identify issues early, saving time and preventing costly repairs.

If unsure about any step, consult a professional to ensure a safe and effective installation, enhancing your car's performance.

Getting Ready for Car Wiring Wire Installation

To install car wiring wire, you need the right tools and materials. Being prepared makes the job easier and avoids mistakes. This section explains what you need to begin.

Tools You’ll Need for Car Wiring Wire Work

Using proper tools helps you work faster and better. Here are some important tools for the job:

Wire Strippers: Tools like Summit Racing Wire Stripper cleanly strip wires. They have guides and cutters to make work easier.

Crimping Tools: Good crimpers, like Ratcheting Crimpers from Pertronix, make strong connections. They stop wires from being too loose or too tight.

Multimeter: A digital multimeter checks voltage, resistance, and continuity. It finds problems in the wiring system.

Removal Tools: These tools safely take out connectors without breaking them.

Tape and Harnesses: High-heat OEM tape keeps wires neat and safe.

Having these tools ready makes your work smoother and more professional.

Materials You’ll Need for Car Wiring Wire Work

Choosing good materials is as important as having the right tools. Here’s what you’ll need:

Automotive Wires: Use strong wires like primary wire or battery cables. These wires power lights, sensors, and other parts.

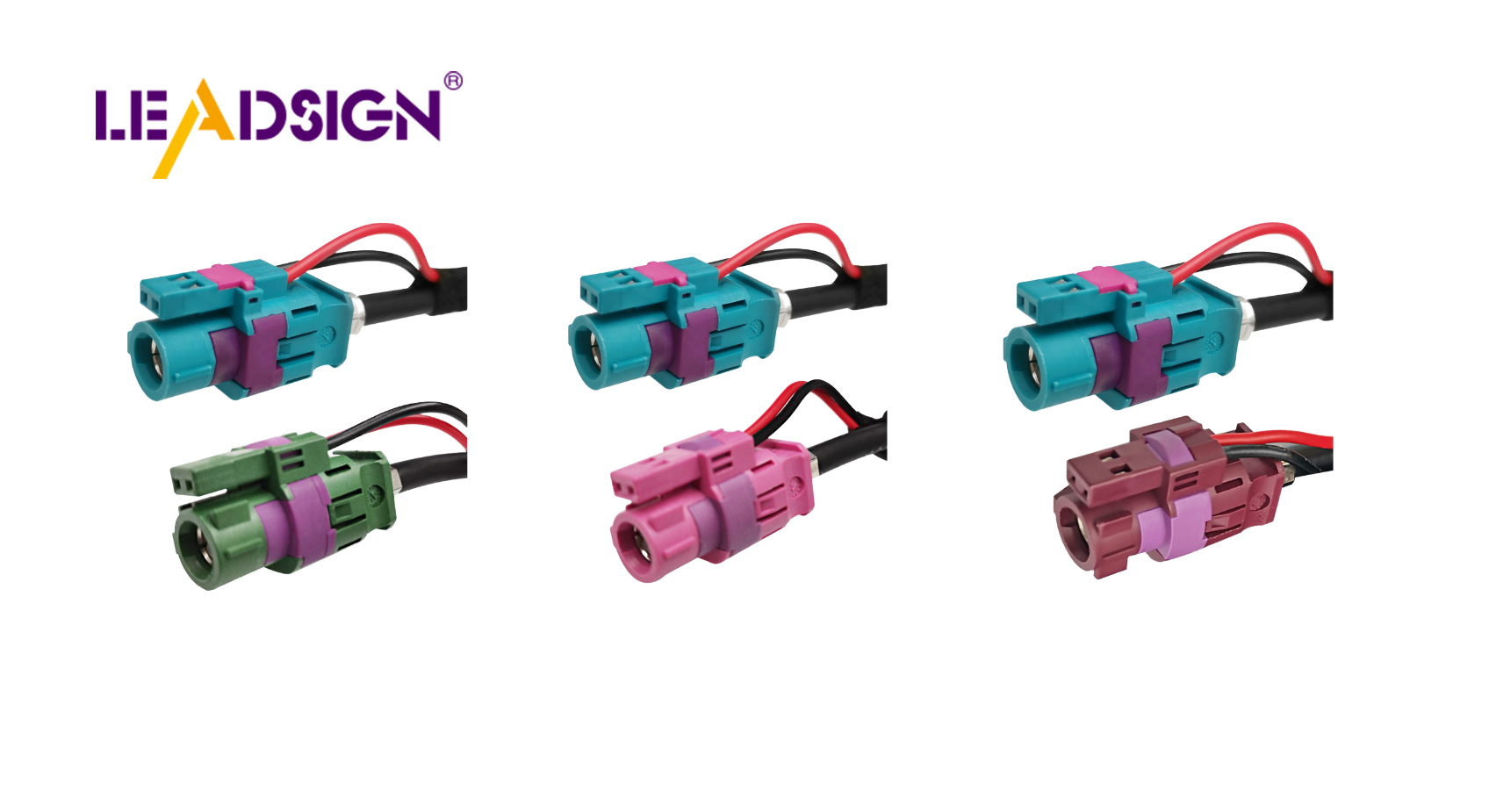

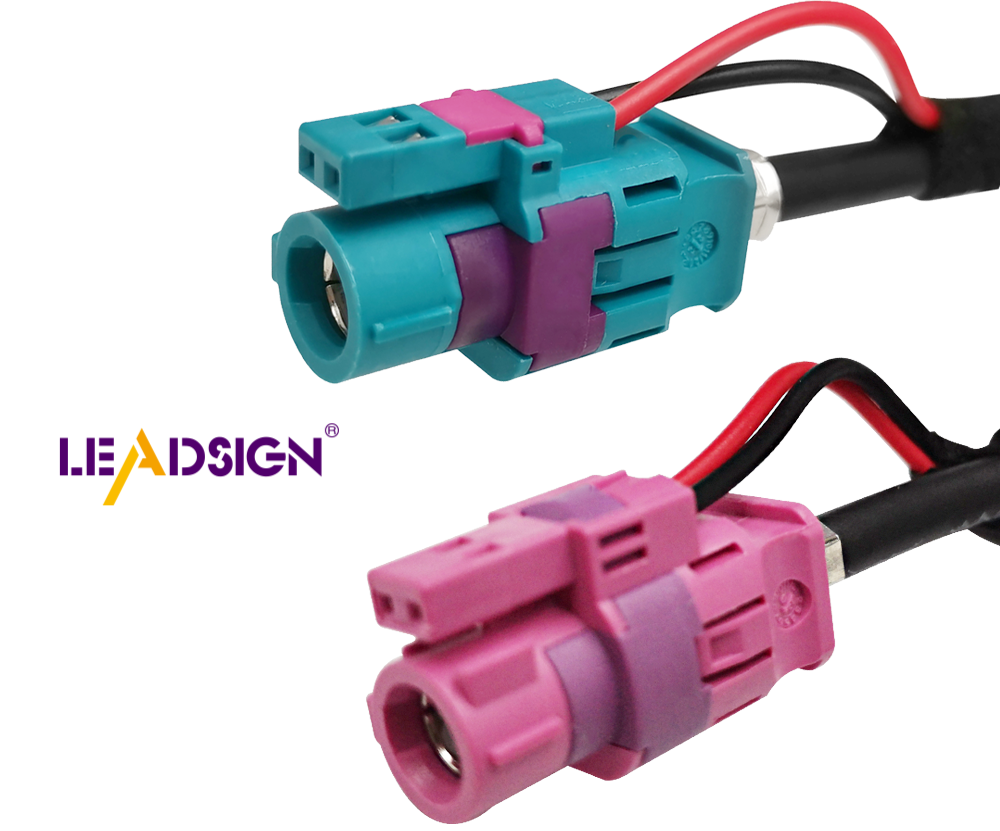

Connectors: Reliable connectors, like HSD connectors, keep data steady and secure.

Insulation Materials: Heat-shrink tubing and tape protect wires from damage.

Fasteners: Clips and zip ties hold wires in place and stop tangling.

Good materials make your car’s electrical system last longer and work better.

Safety Tips to Follow

Safety is very important when working on car wiring wire. Follow these tips to stay safe:

Disconnect the Battery: Always unplug the car battery before starting. This stops short circuits.

Wear Protective Gear: Use gloves and glasses to avoid cuts and sparks.

Work in Open Spaces: Stay in a ventilated area to avoid harmful fumes.

Check Tools and Materials: Look for damage before using tools or materials. Broken tools can cause accidents.

Follow Instructions: Use tools and materials as the manufacturer suggests.

By following these safety steps, you can work safely and confidently.

Understanding the Wiring Diagram for Automotive Electrical Systems

Wiring diagrams help you understand your car's electrical system. They show how parts connect and work together. Learning to read them helps fix problems and install parts correctly.

Key Components and Symbols in a Wiring Diagram

Wiring diagrams use symbols to show parts of the electrical system. Knowing these symbols is important to understand the diagram. Here are some common ones:

Power Sources: A battery symbol shows where electricity starts.

Ground Connections: Horizontal lines show where circuits connect to the car frame.

Switches: A gap in the line shows switches that control electricity flow.

Relays: Rectangles with lines show relays, which manage high-current circuits.

Load Devices: Icons for lights, motors, or speakers show these parts.

Each symbol has a meaning. Knowing them helps you find parts in the system. For example, clear diagrams, like those in audio systems, show all parts and connections. This makes it easier to follow without confusion.

Tips for Interpreting Wiring Diagrams Effectively

Reading wiring diagrams takes focus and a step-by-step method. These tips can help:

Start Simple: Find the power source and ground connections first. These are the basics of any circuit.

Follow the Lines: Trace the lines to see how parts connect. Look at switches, relays, and devices to see electricity flow.

Use Wire Colors: Many diagrams use wire colors to match real wires in your car.

Break It Down: If it looks hard, split it into smaller parts. Focus on one section at a time.

Check Car Guides: Use the diagram made for your car model. This avoids mistakes.

Experts suggest starting with easy circuits, like fog lights, to learn. Practice helps you read even tricky diagrams. Companies like Painless Performance and Ron Francis Wiring offer helpful resources.

By learning wiring diagrams, you can fix issues, add parts, and keep your car's electrical system working well.

Connecting the Battery and Power Source

Hooking up the battery is an important part of car wiring wire work. It makes sure electricity flows properly to power all parts. Follow these steps to connect the battery safely and correctly.

Getting the Battery Ready for Installation

Before connecting, you must prepare the battery. This keeps the system safe and avoids damage. Here’s how to get started:

Look at the Battery: Check for cracks or leaks. Replace it if damaged to stay safe.

Clean the Ends: Use a brush to scrub off dirt or rust on terminals. Clean ends make better connections.

Test the Voltage: Use a multimeter to check the battery’s charge. A full battery shows about 12.6 volts. Charge it if the reading is low.

Set the Battery in Place: Put the battery in its tray securely. Make sure it doesn’t move while driving.

Wear Safety Gear: Always wear gloves and goggles when handling batteries. This protects you from spills or sparks.

Pro Tip: Remove the negative terminal first when taking out the battery. Reconnect it last to avoid short circuits.

Steps to Connect the Power Source

After preparing the battery, connect it to the power source. Follow this guide to finish the job:

Find the Terminals: The positive terminal has a "+" sign and red cover. The negative terminal has a "-" sign and black cover.

Attach the Positive Cable: Connect the positive cable to the "+" terminal. Tighten it well with a wrench.

Attach the Negative Cable: Connect the negative cable to the "-" terminal. Make sure it’s tight to avoid loose connections.

Secure the Wires: Use ties or clamps to keep cables in place. This stops them from moving or tangling.

Check the System: Turn on the car to see if it works. If not, check the cables again for loose ends.

Safety Tip: Never touch both terminals with metal tools. This can cause a dangerous spark.

By following these steps, you can safely connect the battery and power source. Proper setup ensures your car wiring wire system works well and avoids problems later.

Wiring Installation for Automotive Electrical Systems

Good wiring helps your car's electrical system work well. This guide shows how to route wires, connect parts, and check grounding and polarity.

Routing Wires Through the Vehicle

Placing wires properly avoids damage and keeps them neat. Follow these steps:

Plan the Path: Find the safest, shortest way for wires. Stay away from sharp edges or hot areas like the engine.

Use Existing Channels: Check for built-in channels or grommets. These protect and hold wires securely.

Secure the Wires: Use zip ties or clips to keep wires in place. Space them evenly to stop sagging.

Protect the Wires: Cover wires with heat-proof sleeves or conduit. This keeps them safe from wear.

Label the Wires: Use labels or colored tape to mark wires. This helps with future fixes or upgrades.

Pro Tip: Leave a little extra wire length. This avoids tension and allows easy adjustments.

Connecting Wires to Components

Connecting wires to parts is very important. Make sure every connection is strong and safe by following these steps:

Strip the Wire Ends: Remove about half an inch of insulation with a wire stripper. Be careful not to harm the wire strands.

Choose the Right Connector: Pick connectors that fit the wire size. For example, use HSD connectors for fast data wires.

Crimp or Solder the Connection: Use a crimping tool to attach the connector. You can also solder for stronger connections.

Attach to the Component: Connect the wire to the correct terminal or port. Tighten screws or clamps to secure it.

Test the Connection: Gently pull the wire to check if it’s tight. Loose wires can cause problems.

Safety Tip: Check the polarity before connecting wires. Wrong polarity can damage parts.

Grounding and Polarity Checks

Grounding and polarity checks keep the system safe and working. Follow these steps:

Locate the Ground Points: Find where the car frame is grounded. These spots are often marked or near big parts.

Clean the Ground Surface: Remove dirt, rust, or paint from the ground spot. Use sandpaper or a wire brush.

Secure the Ground Wire: Attach the ground wire tightly with a bolt or screw. Make sure it doesn’t move.

Check Polarity: Use a multimeter to confirm polarity. Positive wires go to positive terminals, and negative wires go to the ground.

Test the System: Turn on the system and check if it works. Look for flickering lights or strange sounds.

Reminder: Always use your car’s wiring diagram to avoid mistakes.

By following these steps, you can install wires safely and correctly. Proper routing, strong connections, and careful checks make your car wiring wire system reliable.

Testing and Fixing Car Electrical Systems

Testing and fixing your car's electrical system keeps it working well. This process finds and solves problems, making your car safe and dependable.

Checking the Electrical System

Checking ensures all parts of the electrical system work right. Follow these steps to check everything:

Look at the Wires: Check for broken wires or melted covers. Bad wires stop electricity from flowing.

Use a Multimeter: Set it to check voltage or connections. Test wires to see if electricity flows correctly.

Check Battery Power: A good battery should show about 12.6 volts. If it’s low, charge or replace it.

Test Each Part: Turn on lights, wipers, and other parts. Make sure they work without flickering or delays.

Check Fuses and Relays: Take out fuses and look for breaks. Replace broken ones with the same type.

Tip: Always test again after fixing to make sure it works.

Regular checks find problems early and save money on big repairs.

Fixing Common Wiring Problems

When something goes wrong, fixing helps find and solve the issue. Use these steps to fix common wiring problems:

Split the System: Break it into smaller parts. Test each part to find the problem.

Check for Too Much Load: Too many devices can blow fuses. Unplug extras to lower the load.

Fix Loose Connections: Loose or rusty connections stop electricity. Tighten or clean them to fix it.

Find Short Circuits: Wires touching by mistake cause short circuits. Use a multimeter to find and fix them.

Replace Bad Covers: Old or broken covers leave wires unprotected. Use strong materials like PVC to cover them.

Reminder: Always unplug the battery before fixing wires to stay safe.

By following these steps, you can fix most wiring problems yourself. A careful method saves time and avoids mistakes.

Good car wiring needs a clear plan and careful work. Follow steps one by one, starting with preparation and ending with testing. Make sure every connection is tight and works well. Always put safety first. Wear gloves, unplug the battery, and check your work twice to avoid errors. Think logically to solve problems and work step by step for accuracy. Take your time with each task. If you're not sure, ask a professional for help. This way, you can build a safe and dependable electrical system that improves your car's performance.

FAQ

What types of wires are commonly used in vehicles?

Cars use primary wires, battery cables, and special wires like speaker cables. Primary wires handle most tasks, while battery cables link the battery to the car’s system. For fast data transfer, shielded wires like HSD connectors are used. These wires are strong and work well in tough conditions.

How do I determine the correct wire gauge for my project?

The wire gauge depends on the current and wire length. Thicker wires (lower numbers) carry more current and go longer distances safely. Use a wire gauge chart to decide. For example, 12-gauge wires are good for lights, while 4-gauge wires connect the battery to the starter.

Why is proper insulation important for automotive wiring?

Insulation keeps wires safe from heat, water, and damage. Materials like PVC or heat-shrink tubing stop short circuits and rust. Shielded wires reduce interference in high-performance systems. Always pick insulation that fits the area, like heat-proof types near the engine.

Can I customize my car’s wiring system?

Yes, you can change your car’s wiring to add features or improve it. Popular upgrades include new audio systems, extra lights, or advanced sensors. Use good-quality wires and connectors for safety. Follow the car’s wiring diagram to avoid mistakes.

What are the basic tools needed for automotive wiring?

You’ll need wire strippers, crimping tools, a multimeter, and removal tools. Wire strippers remove insulation neatly, and crimping tools make tight connections. A multimeter checks voltage and connections. Removal tools help take out connectors without breaking them.

How do I protect wires from damage during installation?

Run wires through safe paths or cover them with sleeves to avoid sharp edges and heat. Use zip ties or clips to hold wires in place. Label wires with tape or tags to find them easily later. Protecting wires helps them last longer.

What should I do if my car’s electrical system isn’t working?

First, check wires for cuts or melted spots. Use a multimeter to test voltage and connections. Make sure the battery is charged and connections are tight. Replace blown fuses with the same type. If problems continue, ask a professional for help.

Are there industry standards for automotive wiring?

Yes, car wiring must meet safety and performance rules. Wires should be made for cars, with strong insulation and durability. Using shielded wires and following best practices ensures your car’s system works well and safely.

Is soldering better than crimping for wire connections?

Soldering makes strong, lasting connections but takes more time and skill. Crimping is quicker and easier, so it’s better for most car projects. Both work well if done right. Pick the method that fits your project and make sure connections are secure.

How can I learn more about automotive wiring?

You can read books, watch videos, or visit websites about car wiring. Learn about 12V systems, wire sizes, and circuit safety. Start with easy projects, like installing a stereo, to practice. Over time, you’ll feel ready for harder tasks.

See Also

Understanding Fakra HSD LVDS 4 Pin Connector Wiring

An Overview of Ford Fakra Connector Types

In-Depth Insights on HSD Connectors Explained

Fundamentals of HSD Connectors for Automotive Applications

Enhancing Data Transfer in Vehicles with Advanced Connectors