Beginner's Guide to Car Wiring with 2 Pin Automotive Connectors

Have you thought about wiring a car with 2 pin connectors? You're in the right spot! Knowing car wiring wire is important for your car to work well. Wiring problems can cause unexpected issues, like broken lights or a weird engine. By learning basic car wiring, you can stop sudden breakdowns and expensive fixes. Remember, anything that stops the electrical flow can cause trouble. So, let's learn the basics and make your car's electrical system great!

Key Takeaways

Understanding the importance of car wiring can prevent unexpected issues and costly repairs.

Equipping yourself with essential tools like wire strippers, a multimeter, and crimping tools is crucial for effective car wiring.

Familiarize yourself with different wire types and their functions to enhance your knowledge of your car's electrical system.

Follow a step-by-step process for connecting 2 pin connectors to ensure secure and reliable connections.

Regularly check for common wiring problems, such as loose wires and rust, to maintain your car's electrical health.

Use a multimeter to test connections and ensure everything is functioning properly after wiring.

Practice makes perfect; the more you work on car wiring, the more skilled and confident you'll become.

Tools and Materials Needed for Car Wiring

When starting car wiring, having the right tools is key. Let's see what you need.

Important Tools for Car Wiring

To make wiring easy, get these tools:

Wire strippers and cutters

Use wire strippers and cutters to get wires ready. They help take off the cover without hurting the wire. This is important for good connections.

Multimeter

A multimeter helps find electrical problems. It checks voltage, current, and resistance. Knowing how to use it can stop many problems.

Crimping tool

A crimping tool is needed to attach connectors to wires. It makes sure connections are tight and safe.

Needed Materials for Wiring a Car

Get these materials to wire your car well:

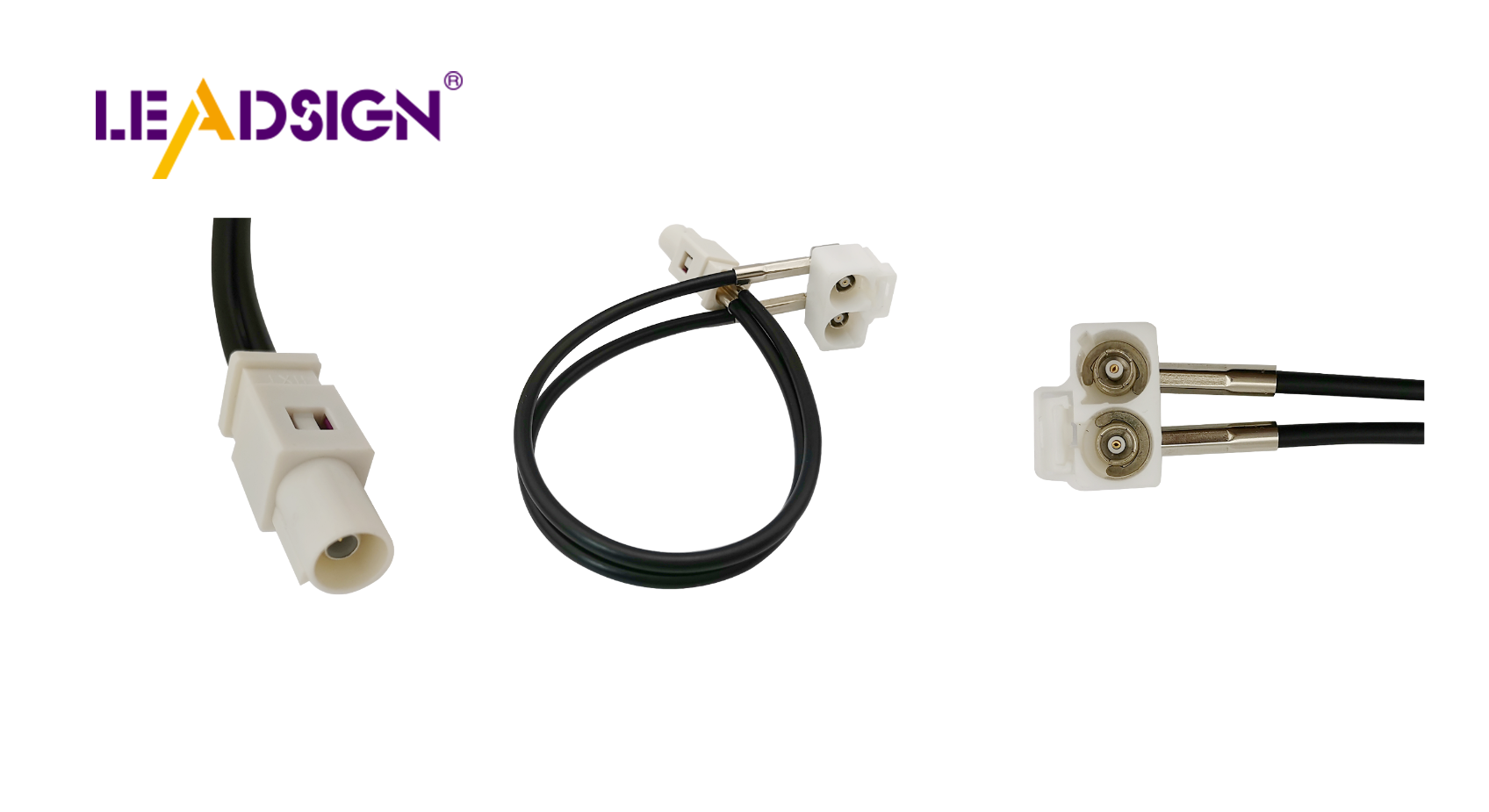

2 pin automotive connectors

These connectors join wires safely. They help power and signals move well in your car.

Electrical tape and heat shrink tubing

Use tape and tubing to keep connections safe. They stop water and dirt from causing problems.

Different wire types

Your car needs different wires. Some carry power, others complete circuits. Good wires keep your car's system working well.

By having these tools and materials, you're ready for car wiring. Check and fix your wiring often to keep your car running well.

Understanding Car Wiring Wire Types and Functions

When you start learning car wiring, knowing wire types is key. Let's see what each wire does in your car.

Types of Wires in Vehicle Wiring

In cars, wires have different jobs. Here are the main ones:

Primary wire

The primary wire is very important. It moves power from the battery to parts like lights and radios. It's usually made of copper because copper is great for carrying electricity. Almost all car wires are copper.

Ground wire

The ground wire is crucial too. It lets electricity go back to the battery. This helps everything work right. Without it, parts might not work well. It also stops too much electricity from causing harm.

Wire Functions in Car Wiring

Knowing what wires do helps you understand your car better. Let's look at their jobs:

Power distribution

Power distribution means sending power to car parts. The primary wire does this. It makes sure each part gets power to work. From starting the engine to turning on lights, it's needed.

Signal transmission

Signal transmission is about sending messages between parts. It helps them talk to each other. Like when you press the brake, a signal turns on the brake lights. This makes sure your car listens to you.

By knowing these wires and their jobs, you can see how your car works. This helps you fix wiring with confidence and keep your car running well.

Step-by-Step Guide to Using 2 Pin Connectors

Ready to dive into the world of automotive wiring? This step by step guide will walk you through using 2 pin connectors. Let's get started!

Preparing the Wires for Connection

Before you connect anything, you need to prepare the wires properly.

Stripping the wire ends

First, grab your wire strippers. Carefully remove the insulation from the ends of the wires. Make sure you don't cut into the wire itself. You want clean, exposed wire for a solid connection.

Choosing the right connector size

Next, pick the right connector size. The connector should fit snugly over the wire ends. Too loose, and the connection won't hold. Too tight, and you might damage the wire. Check the connector's specifications to ensure a perfect fit.

Connecting the Wires with 2 Pin Connectors

Now that your wires are ready, it's time to connect them.

Inserting wires into the connector

Take the stripped wire ends and insert them into the 2 pin connector. Push them in until they reach the end. This ensures a good electrical connection. Double-check that the wires are secure before moving on.

Crimping the connector

With the wires in place, use your crimping tool. Squeeze the connector firmly to secure the wires. A good crimp keeps the wires from slipping out and ensures a reliable connection. Test the crimp by gently tugging on the wires.

Securing the Connection

You've connected the wires, but you're not done yet. Securing the connection is crucial for long-term reliability.

Using electrical tape

Wrap electrical tape around the connector. This adds an extra layer of protection. It keeps moisture and dirt out, which can cause problems down the road.

Applying heat shrink tubing

Finally, slide heat shrink tubing over the connection. Use a heat source to shrink it tightly around the wires and connector. This seals the connection and provides additional durability.

By following this step by step guide, you can confidently install 2 pin connectors in your car's wiring system. With practice, you'll become more skilled at automotive wiring, ensuring your car runs smoothly.

Common Wiring Problems and Fixes in Car Wiring

When working with car wiring, you might face some usual problems. Let's look at these issues and how to fix them.

Spotting Usual Problems

Knowing common wiring problems helps you fix them fast.

Loose wires

Loose wires often cause electrical problems. They can make lights flicker or stop things from working. Check your wires often. Make sure they are tight. A gentle pull can show if a wire is loose.

Rust

Rust is another common problem. It happens when water gets into connectors. This can stop electricity from flowing. Look for green or white powder on connectors. If you see any, clean them right away. Use a wire brush or sandpaper to get rid of rust.

Fixing Tips for Car Wiring

After finding the problem, it's time to fix it.

Using a multimeter to check wires

A multimeter is great for fixing problems. It helps check if wires are good. Set your multimeter to check continuity. Touch both ends of the wire with the probes. If it beeps, the wire is fine. No beep means the wire is broken.

Changing broken connectors

Sometimes, connectors are too broken to fix. Then, changing them is best. Cut off the old connector. Strip the wire ends and put on a new one. Use your crimping tool to make it tight. This makes sure the connection is strong and stops future problems.

By knowing these common wiring problems and fixes, you can keep your car's electrical system working well. Regular checks and care will help you avoid sudden breakdowns. With practice, you'll get better at fixing wiring problems.

Checking and Finishing the Wiring

You've connected everything well. Now, let's make sure it works. Testing and finishing the wiring makes your car's system run smoothly.

Checking Car Wiring Connections

Testing is important. It helps find mistakes early.

Using a multimeter to check connections

Use a multimeter to test wires. Set it to check if electricity flows. Touch both wire ends with the probes. If it beeps, the connection is good. No beep? You might need to fix it. This test can stop future problems.

Making sure everything works

After checking, turn on the car's parts. See if lights are bright and the radio plays well. If not, check the wires again. Make sure they are tight and in the right place.

Finishing the Setup

After testing, finish the setup. This keeps wires safe and working well.

Keeping wires in place

Use ties or clips to hold wires. This stops them from moving and breaking. Keep wires away from hot or sharp places. Safe wires last longer and prevent problems.

Doing a final check

Look over your work one last time. Check for loose wires or open connections. Make sure all connectors are tight. A good check now stops issues later. Once happy, your wiring is done!

By doing these steps, your car's wiring stays strong. Regular checks keep your car running well. With practice, you'll get better at wiring, making future jobs easier.

Car wiring is like the veins in your body. It helps your car work well. Good wiring makes sure everything runs smoothly. As you practice, you'll get better at wiring. Each connection you make helps your car work better.

"The wires and connectors are like veins. They carry power and signals to different parts."

Keep learning and trying new things. With each project, you'll get smarter and more skilled. Your car will be happy!

FAQ

What is a wiring harness, and why is it important?

A wiring harness is a bunch of wires and connectors in your car. It links electrical parts so they work together. Think of it like your car's nervous system. Without it, the car's electrical parts might not work right.

How can I prevent car wiring issues?

To stop wiring problems, do regular checks. Here are some tips:

Inspect regularly: Look for worn-out wires or loose connections.

Keep it clean: Dirt and water can cause rust. Clean wires often.

Use quality materials: Buy good wires and connectors for long-lasting use.

Why do my car lights flicker?

Flickering lights mean a loose connection or bad wiring harness. Check if connections are tight. If it keeps happening, look for damage or rust in the wiring harness.

How do I choose the right wire size for my car?

Pick wire size based on the current it carries. Bigger currents need thicker wires. Check your car's manual or ask an expert to pick the right size.

Can I fix a broken connector myself?

Yes, you can fix a broken connector with tools. Use a crimping tool to attach a new connector to the wire ends. Make sure it's tight to avoid future problems.

What should I do if I find corrosion on my connectors?

If you see rust, clean it fast. Use a wire brush or sandpaper to remove it. After cleaning, add a protective layer to stop more rust.

How often should I check my car's wiring?

Check your car's wiring every few months or if you see problems. Regular checks help find issues early and save money on repairs.

Is it safe to work on car wiring myself?

Working on car wiring is safe if careful. Always disconnect the battery first. Use the right tools. If unsure, ask a professional to stay safe.

See Also

Understanding HSD Connectors for Automotive Applications

Essential Insights into HSD Connectors Explained

Exploring Ford Fakra Connectors: A Detailed Overview

Fakra HSD LVDS 4 Pin Connector: Wiring Made Simple

Fakra Connectors Explained: Benefits, Uses, and Setup Advice