What Are the Different Automotive Wire Connectors Types

Car wire connectors are important for safe electrical connections. They connect parts in your car, like lights and sensors. There are various automotive wire connectors types, such as butt connectors and ring terminals, each with special uses. Some, like FAKRA connectors, work well for high-frequency tasks. Picking the right connector keeps your car working safely. As car wiring gets more complex, knowing these connectors helps keep your car running.

Key Takeaways

Understanding different types of automotive wire connectors, such as butt connectors and FAKRA connectors, is essential for safe and effective car wiring.

Choose the right connector based on your specific needs, considering factors like wire size, application, and environmental conditions.

Utilize heat shrink connectors in wet or oily areas to ensure a strong, moisture-proof seal that enhances durability.

For frequent connections, opt for bullet connectors or quick disconnects to save time and simplify maintenance.

Solder wire connectors provide a permanent and reliable connection, ideal for high-demand applications like motor wiring.

Always prioritize quality by selecting connectors made from strong materials, as this will enhance the longevity and reliability of your car's electrical systems.

Follow proper installation techniques, such as crimping or soldering, to prevent loose connections and ensure safety in your vehicle's wiring.

Common Types of Automotive Wire Connectors

Butt Connectors

Butt connectors join two wires securely and reliably. They work by crimping wires inside a small tube. First, strip the wire ends and insert them into the connector. Make sure the wires fit tightly before crimping the barrel. This step ensures a strong connection. There are different types, like non-insulated, vinyl-insulated, and heat-shrink. Heat-shrink ones are best for wet or oily areas. They seal out moisture and protect the connection. These connectors are common in cars, like for trailer or motor wires.

Ring Terminals

Ring terminals have a round opening that fits over screws. This design makes them secure and long-lasting. Use them to connect wires to batteries or grounding points. They come in insulated and non-insulated options. Insulated ones prevent electrical shorts, making them safer. These terminals are strong and dependable. That’s why they are often used in car wiring systems.

Spade Terminals

Spade terminals have a U-shape for easy connections. They are great for wires you connect and disconnect often. Examples include speaker or sensor wires. They come in male and female types for different setups. Insulated spade terminals add safety by covering live wires. These terminals are popular in cars because they are simple and useful.

Bullet Connectors

Bullet connectors are great for quick and easy wire links. They have a round male end that fits into a female socket. This creates a strong and secure connection. Use them when wires need frequent connecting and disconnecting. Examples include trailer wires or car lights.

To use bullet connectors, strip the wire ends first. Attach the male and female parts with crimping tools. Make sure they fit tightly to avoid loose wires. Insulated bullet connectors stop accidental short circuits, adding safety. Non-insulated ones work where insulation isn’t needed. These connectors are handy in cars because they are simple and flexible.

Quick Disconnects

Quick disconnects, also called slide connectors, are easy to use. They have a flat male blade and a matching female slot. These are perfect for wires you need to take apart often. Examples include motor wires or sensor setups.

To install quick disconnects, strip the wire ends and crimp them tightly. Push the male and female parts together until they click. Insulated versions protect against electrical shorts, making them safer. They come in different sizes to fit various wire thicknesses.

Quick disconnects are popular for car wiring because they save time. They make repairs and maintenance easier while keeping connections strong.

Specialized Automotive Wire Connectors

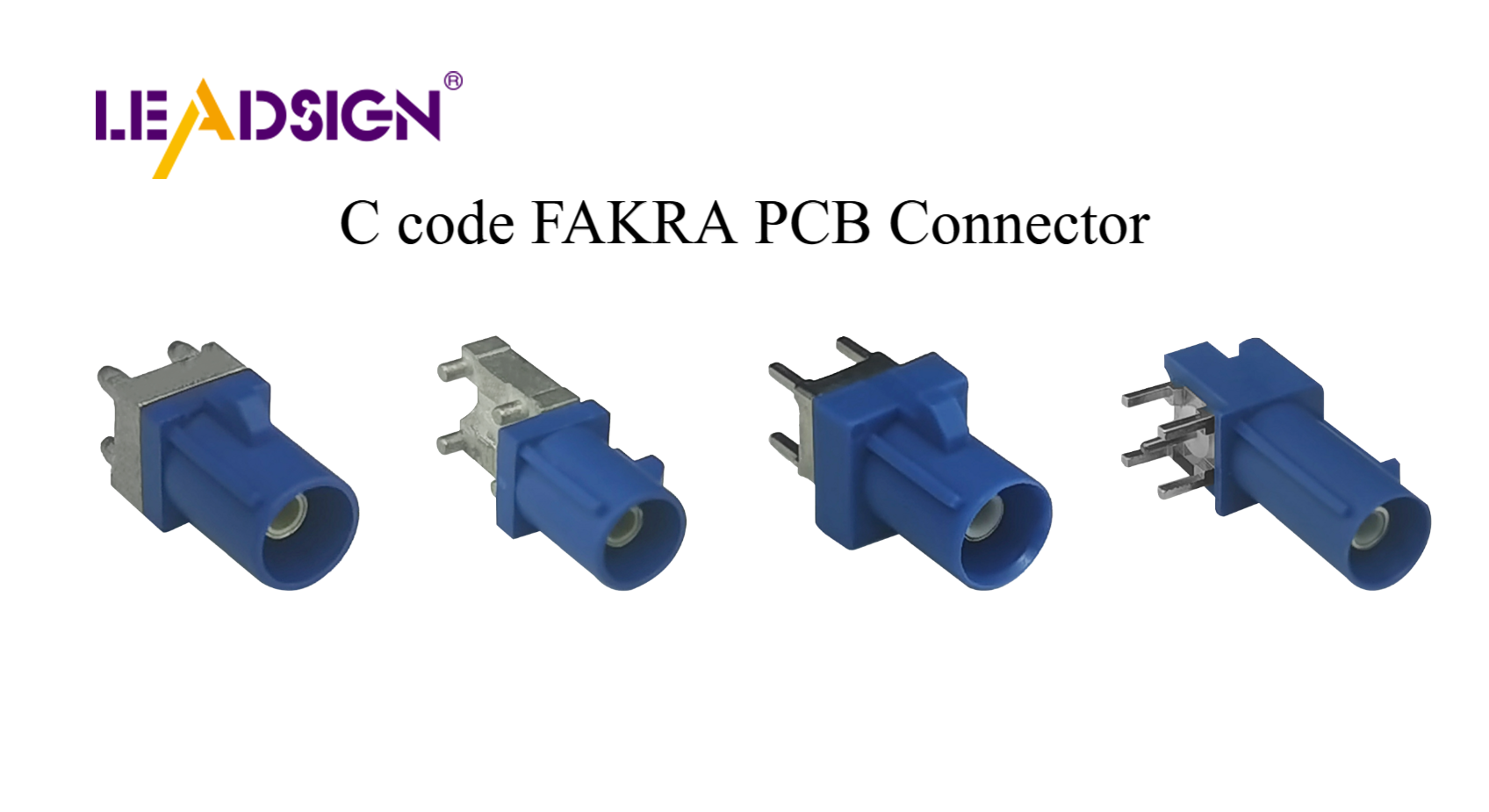

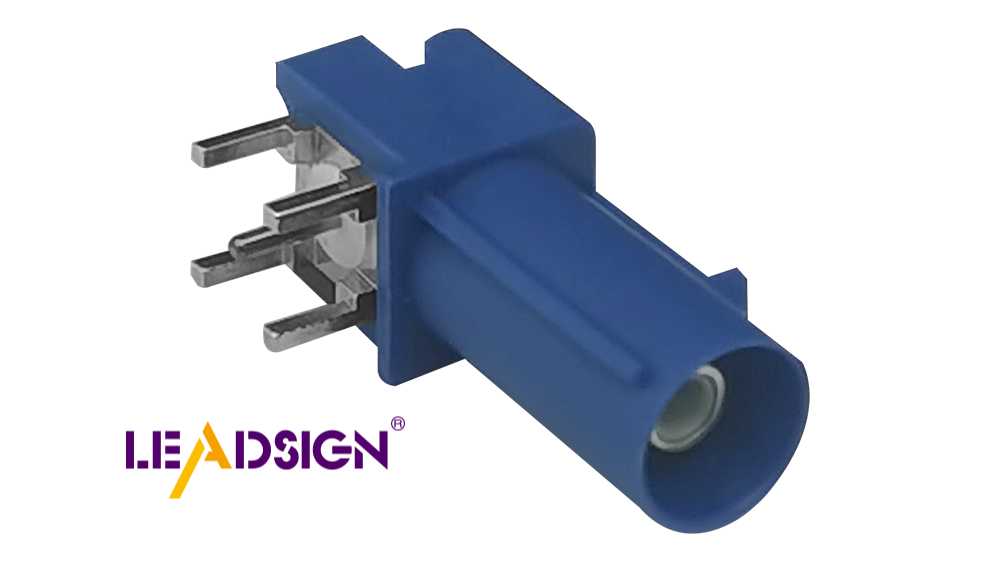

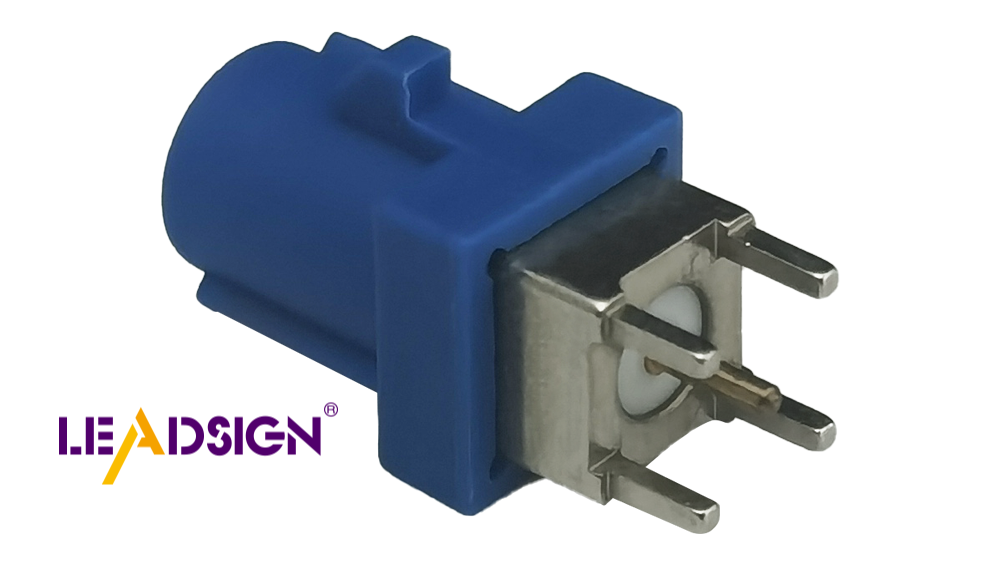

FAKRA Connectors

FAKRA connectors are used for high-frequency car systems. They are found in GPS, radios, and infotainment setups. These connectors send data reliably, even in tough conditions. Their design prevents mistakes, making them safe and easy to use.

FAKRA connectors have many advantages. They handle frequencies up to 6 GHz. They also support data speeds up to 8 Gbps. Waterproof versions work well in outdoor areas. Their locking system keeps them secure during use. You can pick from straight, angled, or panel designs. These features make them great for advanced car systems.

Heat Shrink Connectors

Heat shrink connectors seal wires tightly and keep them dry. They are perfect for wet or oily places. Use them for trailer or motor wire connections. The heat shrink tubing covers the crimped part of the wire. This keeps out water and dirt, making the connection last longer.

To use heat shrink connectors, strip the wire ends first. Crimp the wires inside the connector securely. Then, heat the tubing to shrink it around the wires. This creates a strong seal that protects against damage. These connectors are great for car wiring that needs to last.

Solder Wire Connectors

Solder wire connectors make strong and lasting wire links. They combine soldering and heat shrink for better results. Use them where a permanent connection is needed, like motor wires.

To install solder wire connectors, insert stripped wires into the connector. Heat the solder ring until it melts and joins the wires. The tubing shrinks to seal and protect the connection. These connectors reduce signal loss and keep power steady. They are ideal for advanced systems like electric cars.

Technical Details and Features

Types of Materials (Plastic, Metal, Rubber)

Car wire connectors are made from different materials. Plastic ones are light and don’t rust, so they work well in most cars. They also insulate wires and are cheap to make. Metal connectors, like copper or aluminum, are strong and conduct electricity well. These are used for powerful connections, like motor wires. Rubber connectors are flexible and protect against water or shaking. They are great for places with vibrations or moisture. Pick the right material based on your needs and wires.

Protection from Environment (Waterproofing, Temperature Limits)

Protecting connectors from the environment is very important. Waterproof connectors keep water out, so they work well in wet areas. Heat shrink connectors block water and dirt, making them good for outdoor or engine use. Temperature limits are also key. Many connectors handle extreme heat or cold, from -40 °C to +105 °C. This is important for advanced cars like electric ones. Choosing the right connectors helps your car’s wiring last longer and stay safe.

Electrical Features (Impedance, Frequency, Data Speeds)

Electrical features show how well a connector works. Impedance, measured in ohms, affects signals. For systems like GPS, 50 Ω connectors are best. Frequency is also important. Some connectors, like FAKRA, handle up to 6 GHz, which is great for communication systems. Data speeds matter too. Good connectors support up to 8 Gbps for fast data. These features make some connectors perfect for modern cars that need strong and quick connections.

Picking the Right Connector

Choosing the right connector keeps your car’s wiring safe. With many options, knowing key details helps you decide better.

Things to Think About (Use, Wire Size, Pin Count)

Think about how you’ll use the connector. Different car systems need specific connectors. For example, GPS systems need FAKRA connectors. Simple tasks may only need butt or spade connectors.

Wire size is also important. The connector must fit the wire thickness. A wrong size can cause loose wires or failures. Always check the wire size on the connector label.

Pin count matters too. Multi-pin connectors are good for complex systems like engines. Single-pin connectors, like bullet ones, work for simple setups like lights.

Ways to Install (Crimping, Soldering, Heat Shrink)

Different connectors need different installation methods. Crimping is common and easy. Use a crimping tool to attach the connector to the wire. It’s fast and works well for most car wiring.

Soldering makes a stronger connection. Melt solder to join the wire and connector. It’s best for tough jobs like motor wiring but needs more skill.

Heat shrink connectors add extra protection. Crimp the wire, then heat the tubing to seal it. This keeps out water and dirt, great for wet areas.

Helpful Tips for Choosing

Start by knowing what your project needs. Think about the connection type, environment, and electrical needs. For waterproofing, pick heat shrink or Weather Pack connectors.

Choose good-quality connectors. Strong materials like tinned copper last longer and work better. Avoid cheap ones that might break easily.

Keep different connectors ready. Having options saves time during repairs or installs. Follow the maker’s instructions for proper installation. This prevents problems and keeps your car’s wiring reliable.

Car wire connectors are important for your car’s electrical systems. Each type has a specific job, from simple to advanced uses. FAKRA connectors, for example, handle high-frequency tasks. Choosing the right connector means thinking about wire size and type. You should also consider where it will be used, like wet areas. Tested connectors last longer and work better in tough conditions. Knowing how these connectors work helps you pick the best ones. This keeps your car’s wiring safe and working well.

FAQ

What are automotive wire connectors used for?

Automotive wire connectors join wires in cars securely. They connect parts like lights, sensors, and systems like GPS or radios. These connectors help your car work safely and properly.

How do I choose the right automotive wire connector?

Think about where and how you’ll use the connector. For wet areas, use heat shrink connectors. For GPS or radios, pick FAKRA connectors. Always match the connector to the wire size and job.

What makes FAKRA connectors special?

FAKRA connectors handle high signals up to 6 GHz. They also support fast data speeds up to 8 Gbps. Their locking system keeps them secure, and waterproof ones work in tough places. They are great for GPS and radios.

Are heat shrink connectors waterproof?

Yes, heat shrink connectors block water and dirt. When heated, they shrink tightly around wires. This makes them perfect for outdoor or engine wiring.

What is the difference between crimping and soldering?

Crimping uses a tool to press the connector onto the wire. It’s quick and easy. Soldering melts metal to join wires, making a stronger bond. Crimping is faster, but soldering lasts longer.

Can I use the same connector for all car wiring?

No, different jobs need different connectors. Butt connectors join wires, while ring terminals attach wires to screws. Picking the right type keeps your car safe and reliable.

Why is material choice important for connectors?

The material affects how strong and useful the connector is. Plastic connectors don’t rust and are light. Metal ones, like copper, carry electricity well. Rubber ones protect against water and shaking.

How do I prevent loose connections?

Make sure the connector fits the wire size. Use the right tools to crimp or solder. Tight connections make your car’s wiring safer and more reliable.

What are quick disconnects used for?

Quick disconnects make it easy to connect and disconnect wires. They are great for parts needing frequent checks, like sensors. They save time and make repairs simple.

Are OEM automotive connectors better?

OEM connectors are high-quality and improve car performance. They are safe and reliable because of their advanced designs. Using OEM connectors makes your car work better and last longer.

See Also

Why Fakra Connectors Are Essential For Today's Vehicles

Understanding HSD Connectors Within The Auto Sector

Significance of Fakra Connectors In Automotive Applications