Custom Automotive Wiring Harness Solutions for Next-Gen Cars

Auto harness connectors are very important in today’s cars. They help electrical systems work together, making cars safer and better. The car industry is changing fast with new technology, especially electric cars. The market for EV connectors is growing quickly. It is expected to grow by 27.1% each year from 2023 to 2030, reaching $10.92 billion. This shows more people want better car connectors that are light, strong, and easy to upgrade. These changes are improving car connectors and pushing new ideas in car systems.

Key Takeaways

Today’s car wiring harnesses are key to safety and performance. They link electrical parts, helping cars work better and last longer.

Lightweight and reusable materials in harnesses improve fuel use and lower pollution. This helps create more eco-friendly car options.

Custom harnesses fit different cars better and work more efficiently. They make designs simpler, save money, and speed up production, helping makers and drivers alike.

Current Problems with Car Wiring Harnesses

Making new cars brings special problems for wiring harnesses. These problems affect cost, how well they work, and the environment. Fixing them early in the design process is very important.

Hard-to-Handle Old Designs

Older wiring harnesses are often very complicated. This makes building and fixing them harder. Keeping costs low and making them lighter is also tough. Companies struggle to make sure all systems work well together. These issues slow down production and make it harder to build more cars. As cars use stronger batteries and smarter tech, simpler harness designs are needed.

Heavy and Bulky Wires

Old harnesses are often big and heavy. This extra weight makes cars less fuel-efficient and slower. For electric cars, heavy wires can lower how far they can go. Space is also a problem as cars now have more tech and connectors. Using lighter materials and easier-to-fit designs can solve these problems. These ideas match what’s happening in car technology today.

Environmental Problems

Old harness materials like plastic and copper hurt the planet. Making and throwing them away causes pollution and wastes resources. For example:

Making plastics and metals uses a lot of energy.

Getting these materials damages nature.

Throwing away parts that can’t be recycled fills up landfills.

Using recyclable materials and standard designs can help the environment. These changes support the move toward greener and smarter cars.

Trends in Automotive Harness Architecture

Domain-Based Electrical Systems

Modern cars are getting more advanced, but domain-based systems make things simpler. These systems split the car into zones, each with its own wiring and connectors. This setup makes the harness lighter, which can weigh up to 150 pounds in older designs. For electric cars, lighter harnesses help them go farther and perform better.

These systems are also tougher. Strong connectors keep power and data flowing, even in tough conditions. This is very important for features like advanced driver assistance systems (ADAS). Fixing problems is easier too. You can repair specific zones without much hassle, saving time and money. Plus, software updates can be done remotely, so you don’t need to visit a repair shop.

Modular and Scalable Designs

Breaking harnesses into smaller parts is changing how they’re made. Smaller sections make assembly more accurate and reduce mistakes. This also lowers costs because manufacturers can produce parts in bulk, making cars cheaper.

For you, this means cars are built faster and can be customized more easily. Pre-made parts speed up production and are tested for quality. If something breaks, only the damaged part needs replacing, not the whole system. This saves money and gets your car fixed quicker.

Lightweight and Durable Materials

New materials are making harnesses lighter and stronger. Engineers now use heat-resistant materials for better performance in tough conditions. Lightweight options like aluminum and special composites are popular. These materials make cars lighter, improving fuel efficiency and helping electric cars go farther.

Caring for the planet is also important. Companies are using recyclable materials for insulation and connectors. This helps the environment while keeping the harness strong and reliable.

Innovations in Advanced EV Connectors

High-Speed Data Transmission Solutions

New EV connectors are changing how electric cars share data. They now allow faster data transfer, which is key for modern cars. For example:

Fakra connectors are used for sensors and high-frequency tasks.

In-vehicle Ethernet connects car systems, enabling features like ADAS.

High-speed connectors support HD video and smart car infotainment.

Better materials and lighter designs improve how they work. The 12mm Universal Power Connector (UPC) uses RADSOK tech for strong connections. It needs less force to connect and lasts longer. These upgrades make electric cars more reliable, even in tough conditions.

Enhanced Safety and Reliability Features

Safety is very important for EV connectors. New connectors can handle heat, moisture, and shaking. This keeps connections secure in hard conditions. Many battery connectors now have built-in fuses. These fuses stop problems like overheating or too much current, preventing fires. Heat-resistant materials also lower the chance of thermal runaway, a big safety risk. These features ensure steady power flow, making EVs safer and more dependable.

Integration with Digital Infotainment Systems

EV connectors are key for linking digital infotainment systems. They power and connect in-car tech like screens and displays. Fast data transfer supports advanced features like interactive dashboards. These connectors also help car networks talk to each other, creating a smooth experience. As EVs become smarter, demand for better connectors grows. This shows people want more fun and high-tech options in their cars.

Customization Options for Car Makers and Drivers

Special Designs for Different Cars

Custom wiring harnesses are made to fit specific cars perfectly. Whether it’s an electric car, hybrid, or regular car, these designs match the car’s needs. For example:

They fit tight spaces in hybrid cars.

They handle high power in electric cars.

This makes the car work better with systems like screens and safety tech. By focusing on what the car needs, you get better performance and reliability.

Saving Money and Improving Performance

Custom harnesses help save money and make cars work better. Here’s how:

Simple designs make wiring easier and reduce signal problems.

Strong materials protect wires from damage in tough conditions.

Smart tech like CAN bus makes wiring faster and data clearer.

Modular parts allow quick upgrades and faster car building.

Testing ensures the harness is safe and works well.

These ideas cut costs and improve how the harness works. For electric cars, this means saving energy and making parts last longer.

Helping the Environment with Custom Harnesses

Custom harnesses can be better for the planet. Using eco-friendly materials like recyclable plastics reduces waste. Factories can use less energy and cleaner power sources. Recycling old parts helps cut down on trash. These steps match the push for greener cars. Custom harnesses not only protect nature but also meet today’s green standards.

Case Studies and Real-World Examples

Tesla’s Easy-to-Use Wiring for EVs

Tesla has changed how wiring is done in electric cars. They use a simple system that combines power and data wires into one. This design makes things less complicated and works well with robots. Tesla also uses special paint and glue on the car body instead of regular wires. Parts snap together with unique connectors, making setup quicker and easier.

Tesla’s system uses small controllers linked by a fast communication line. For example, doors now need only two wires instead of many. Their gigabit Ethernet system allows fast communication between car parts. These changes save time, cut costs, and make electric cars work better.

Rivian’s Modular Wiring System

Rivian uses a modular wiring system to make building cars easier. They create ready-made sections that fit together quickly, speeding up production. This design also makes cars lighter and more dependable.

The modular system is easy to fix and change. If one part breaks, you only replace that section, not the whole thing. This saves time and money. Rivian’s focus on modular designs meets the need for flexible and efficient electric cars.

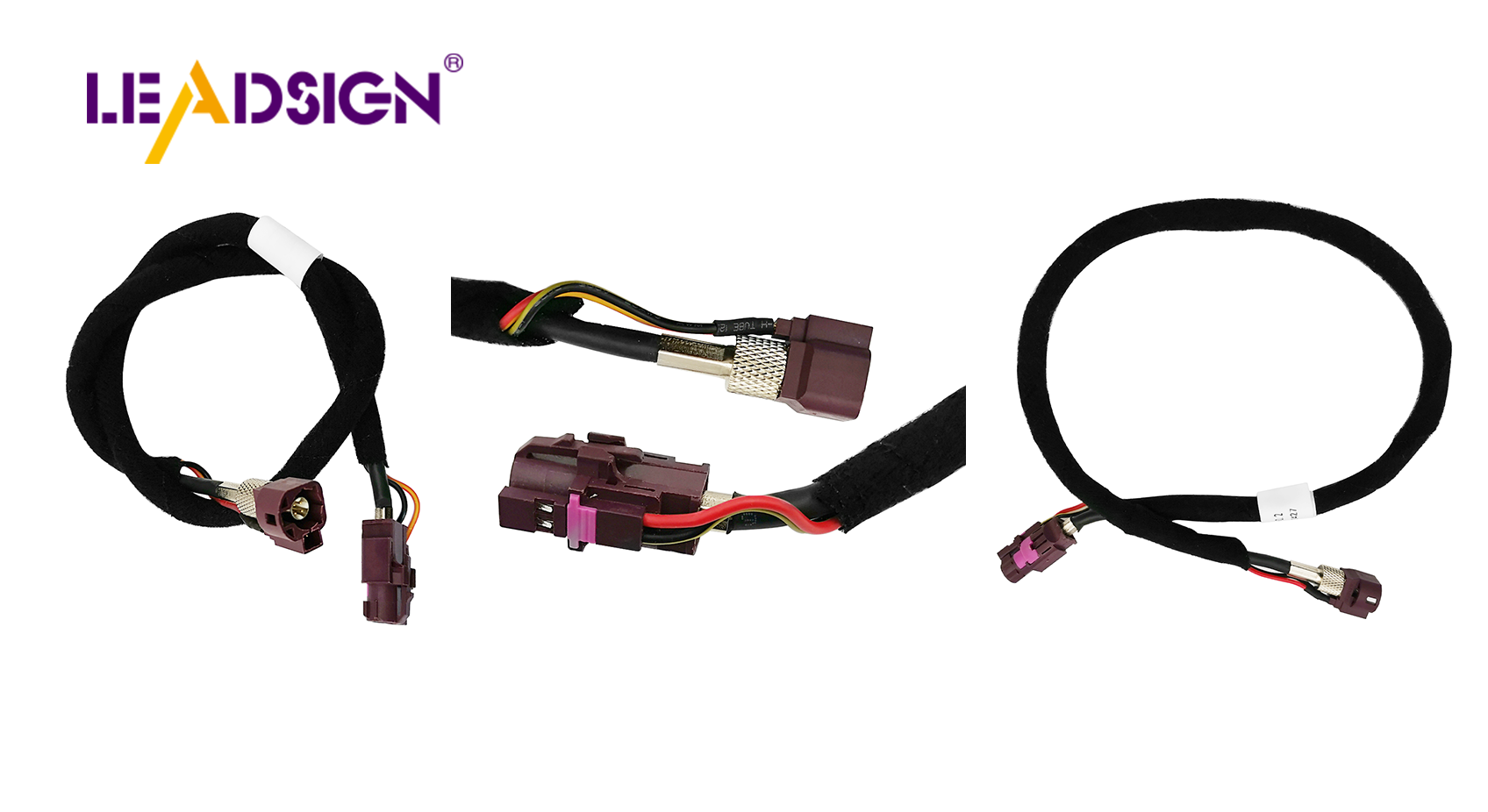

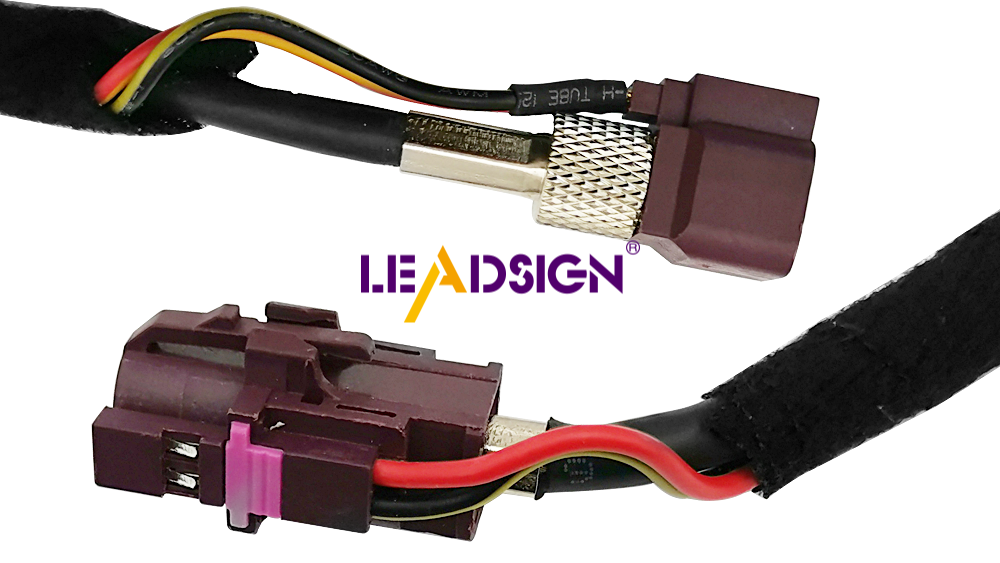

LEADSIGN’s Fast Data Connectors

LEADSIGN makes fast data connectors for modern car systems. These connectors help with quick data sharing for screens, cameras, and sensors. They are made from strong, lightweight materials that last in tough conditions.

LEADSIGN’s connectors work with current systems, making upgrades simple. They are built to handle future technologies too. Tests show they resist heat and shaking, meeting industry rules. These connectors lower repair costs and improve how cars perform, helping create smarter electric vehicles.

The Future of Auto Harness Connectors

AI and Machine Learning in Harness Design

AI is changing how wiring harnesses are made. It helps design better layouts that cost less and weigh less. AI studies data to make wire paths simple and efficient. This cuts down on extra wires and reduces signal problems, improving how electricity flows.

Machine learning can also spot problems early in the design process. Engineers can fix these issues before making the harness. This makes the harness more reliable and cheaper to produce. These tools help meet the needs of electric and self-driving cars.

Trends in Universal and Standardized Connectors

Car makers are now using universal connectors. These connectors have many benefits:

They work with different devices, making them easy to use.

They cost less because they are made in large numbers.

They are dependable and work well in all conditions.

The best part of standard connectors is simpler wiring. Old harnesses needed many designs for one car model. Standard connectors remove this problem, saving time and money.

For you, this means fewer wiring problems and easier upgrades. Standard connectors make car building faster and smarter.

Wiring Harnesses in Fully Autonomous Vehicles

Self-driving cars need special wiring harnesses. These harnesses send data quickly between sensors to make decisions. They also have backup systems to avoid big failures and keep the car running.

Self-driving cars create a lot of data, so strong wiring is needed. Smaller harness designs save space but still work well. For you, this means safer and smarter self-driving cars. These harnesses are key to making self-driving cars possible.

The growth of car harness connectors shows why trends matter. Zone-based systems make designs simpler and fix problems faster. New technology makes harnesses work better and last longer. Custom designs are key to meeting unique car needs. With more electric and self-driving cars, smarter harnesses will improve how cars work in the future.

FAQ

What does a car wiring harness do?

A wiring harness links your car’s electrical parts together. It helps power and data move smoothly between things like lights, sensors, and screens.

Why use lightweight materials in wiring harnesses?

Light materials make cars lighter, saving fuel and energy. They boost performance and are better for the planet by using recyclable stuff.

How do custom harnesses help electric cars?

Custom harnesses save space and deliver power efficiently in EVs. They cut costs, use energy better, and work well with smart features like ADAS and infotainment.

See Also

Streamlining Automotive Data Flow With Innovative Connectors

Boosting Data Transfer Efficiency Through High-Speed Connectors

Transforming Vehicle Connectivity With HFM Connector Benefits

Key Benefits of HFM Connectors for Automotive Applications

Benefits of HSD Connectors for Automotive Entertainment Systems