Wire Connectors Types and Their Role in Automotive Systems

Wire connectors are crucial for safely joining wires. In cars, they ensure reliable connections, enhancing performance and safety. There are various wire connectors types, each serving a specific purpose. For instance, the HSD PCB Connector facilitates fast data transmission, while an ethernet cable connector maintains stable network links. Understanding these options helps you make informed choices, ensuring your car's electrical system operates optimally.

Types of Wire Connectors

Knowing about wire connectors is key for car work. Each type has special features and jobs. Let's look at some common ones used in cars.

Crimp Connectors

Characteristics of Crimp Connectors

Crimp connectors hold wires tight by squeezing a metal sleeve. They come in different sizes for various wires. These are strong and resist shaking, perfect for cars.

Uses in Automotive Systems

In cars, crimp connectors join wires to parts like switches. They keep connections stable, important for electronics to work right. You see them in batteries, lights, and engine controls.

Installation Methods

To use crimp connectors, you need a tool. Strip the wire first. Put it into the connector and squeeze with the tool. Make sure it's tight to avoid problems.

Solder Connectors

Characteristics of Solder Connectors

Solder connectors join wires by melting solder on them. This gives great conductivity and strength. They resist water and rust, good for cars.

Uses in Automotive Systems

Use solder connectors where strong bonds are needed. They're found in wiring harnesses and sensors. They ensure signals move well, crucial for electronics.

Installation Methods

For solder connectors, use a soldering iron and solder. Twist wires together and heat them up. Add solder until it covers the joint smoothly. Let it cool before touching.

Push-In Connectors

Characteristics of Push-In Connectors

Push-in connectors connect wires fast without tools. They have springs that hold wires tightly. Easy to use without crimping or soldering.

Uses in Automotive Systems

In cars, push-in connectors are great for quick fixes or tests. Use them when you need temporary connections or frequent changes.

Installation Methods

To install push-in connectors, strip the wire and push it in. The spring grips it securely. This saves time and cuts down mistakes.

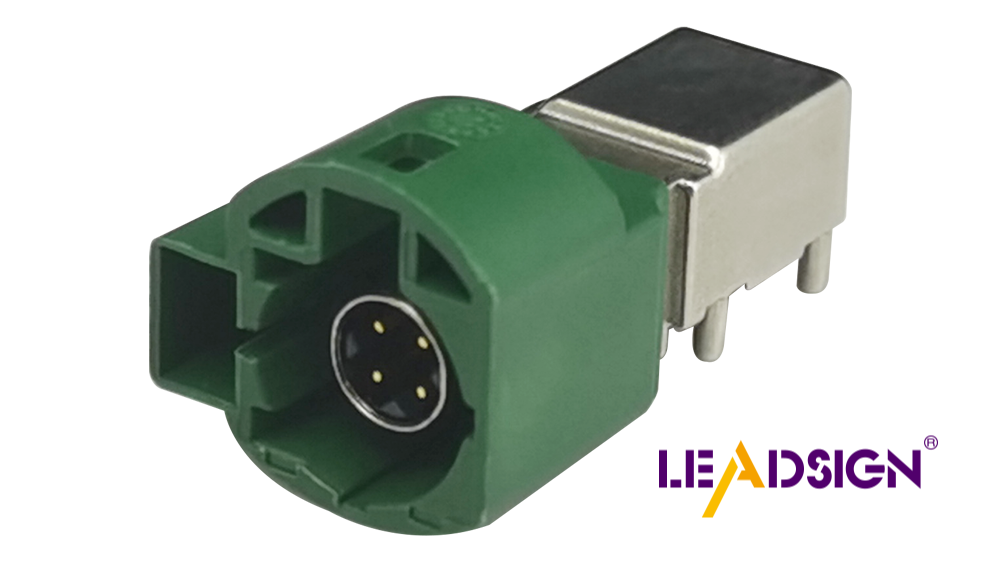

HSD PCB Connector

Characteristics of HSD PCB Connector

The HSD PCB Connector is special. It sends data fast, perfect for cars. It locks in place securely. It's small and fits car needs worldwide. Colors help you use it right.

Uses in Automotive Systems

In cars, the HSD PCB Connector is important. Use it with cameras, USBs, and networks. It helps electronics work well and keeps data moving smoothly.

Installation Methods

To install, be careful. Get the right tools first. Line up the connector with the port. Push gently until it clicks. Don't force it to avoid damage. Check often to keep it working well.

Benefits of Using Wire Connectors in Cars

Better Safety

Stopping Electrical Problems

Wire connectors stop electrical problems. They keep wires tight, so they don't come loose. This helps your car's electric parts work well.

Guarding Against Short Circuits

Wire connectors guard against short circuits. They keep wires covered and apart, stopping bad electric issues. This keeps your car safe and you feel better driving.

Improved Efficiency

Easier Wire Connections

Wire connectors make wire connections easy. You can join wires fast without mistakes. This helps your car run better.

Faster Installation Time

Wire connectors save time when installing. They make connecting wires simple and quick. This lets you do other important things faster on cars.

How to Install and Keep Wire Connectors Working

Right Way to Install

Tools You Need

To put in wire connectors right, get these tools:

Wire cutters

Crimp tool

Soldering iron (for solder types)

Heat gun (for heat shrink covers)

Multimeter (to test connections)

These tools help you work with different connectors well.

Easy Steps to Follow

Do these steps for good installation:

Get Wires Ready: Take off the plastic from wire ends. Show enough wire for tight joining.

Pick the Correct Connector: Choose a connector that fits the wire size and job. This makes sure it fits well.

Connect the Wires:

For crimp ones, put the wire in and use the crimp tool to hold it.

For solder ones, twist wires, heat them with a solder iron, and add solder until covered.

For push-in ones, just push the bare wire in until it clicks.

Check Connection: Use a multimeter to see if electricity flows through. This shows it's working right.

Cover and Protect: Use heat shrink or tape to cover it up. This keeps water and shaking away.

Keeping Connectors Good

Check Often

Look at your wire joins often to make sure they stay tight and work well. Watch for:

Loose joins

Rust or rot

Broken wires

Finding these early stops bigger problems later.

Fixing Usual Problems

If things go wrong, try these fixes:

Loose Joins: Tighten or crimp again. Make sure wires are all in.

Rusty Parts: Clean with a brush. Put on something to stop more rust.

Weak Signals: Look for broken wires or bad connectors. Change them if needed.

By doing this stuff, you keep your car's electric parts working great. Good installs and checks keep your car safe and running well.

Picking the right wire connectors is important for your car. They keep it safe and help it work well. Learn more about wire connectors to know them better. This helps you choose wisely and makes your car perform better. Wire connectors are key in cars, giving strong connections and stopping problems. By choosing good ones, you help your car's parts last longer and stay reliable.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Auto Sector

Significance of Fakra Connectors in Modern Cars

Enhancing Auto Data Transfer: Advanced Connectors and Cables