Why OEM Connectors Matter in Automotive Wiring Connector Types

Car wiring requires various types of automotive electrical connectors to function effectively and securely. These small components play a crucial role in the performance of vehicles. Among the different automotive electrical connectors types available, OEM connectors stand out as the top choice due to their superior quality and reliability. Produced by the same manufacturer as the vehicle, OEM connectors ensure seamless integration and optimal operation within the car's systems. The automotive electrical connectors market is projected to grow by 5.8% annually until 2026, highlighting the increasing significance of understanding the importance of OEM connectors in automotive applications.

Understanding OEM Connectors

What are OEM Connectors?

OEM connectors are made by the same company as the car. This means they fit perfectly and work well with the car's electric parts. They are built to be very good quality.

Why OEM Connectors Are Special

OEM connectors have special features that make them better:

Precision Engineering: They fit exactly right.

High Quality: Made from strong stuff, they last long.

Compatibility: They work well with the car's systems.

Reliability: They keep working well over time.

Why Use OEM Connectors?

Strong and Lasting

OEM connectors are very strong. They can handle heat, shaking, and tough conditions in cars. This strength keeps them working for a long time without breaking.

Fit Well with Car Systems

OEM connectors fit perfectly with car systems. This makes sure everything connects right and works together. The car runs smoothly because of this good fit.

Types of Car Electrical Connectors

Car electrical connectors come in different shapes. Each has a special job in car wiring. Knowing these helps pick the right one for each task.

Common Car Connector Types

Blade Connectors

Blade connectors are flat and fit into slots. They stay connected well, even when the car shakes. This makes them good for cars. They are easy to plug in and take out, which helps with fixing things.

Pin Connectors

Pin connectors have pins that fit into holes. They can connect many wires at once. This keeps the car's electric parts working well. Pin connectors are small, so they fit in tight spaces.

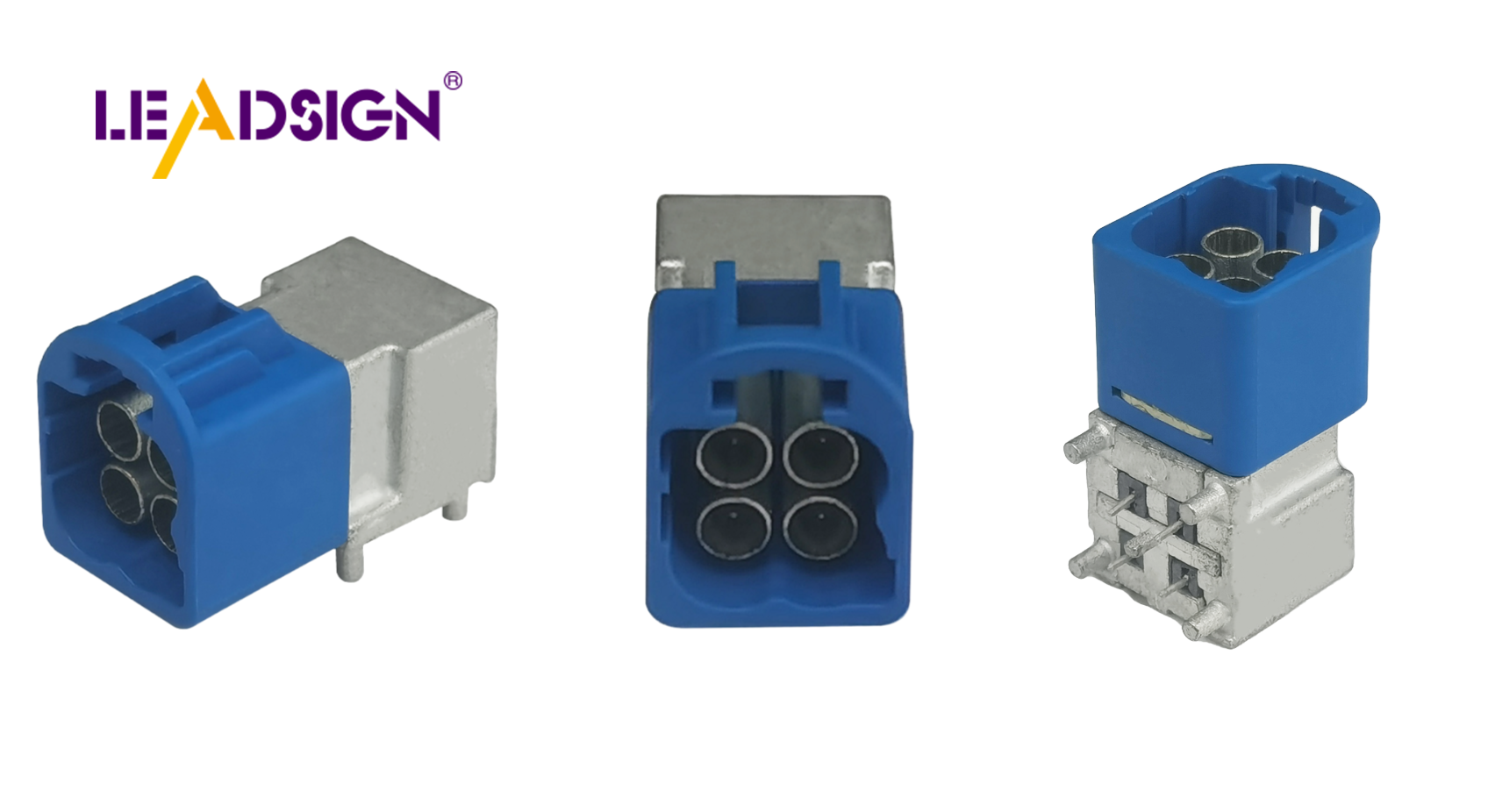

Special OEM Connectors

OEM connectors are made for special car jobs. They work best with certain car systems.

Strong Connectors

Strong connectors handle heat and shaking well. They are used where it is important for things to work right, like engines.

Custom Fit Connectors

Custom fit connectors match certain cars perfectly. This helps the car run better without problems.

Knowing about different car electrical connectors is important for fixing or making cars safe and efficient.

Uses of OEM Connectors in Car Wiring

Engine and Powertrain Systems

Role in Engine Control

OEM connectors are key for engine control. They help the engine control unit (ECU) talk to sensors. This helps the ECU check and change how the engine works. Using OEM connectors are key keeps these links strong and trustworthy. Strong links are important for good engine work and less pollution.

Importance in Power Flow

In power flow, OEM connectors make sure electricity moves well. They link the battery to things like the alternator and starter motor. This makes sure cars start easily and have steady power. OEM connectors are tough against heat and shaking under the hood. This toughness stops power problems and boosts car performance.

Safety and Security Systems

Part in Airbag Systems

OEM connectors are crucial for airbags. They join airbags to safety systems in cars. This ensures airbags work right during crashes. Well-made OEM connectors lower bad connection risks, stopping airbag issues. Using them improves passenger safety by following strict rules.

Use in Anti-Theft Systems

In anti-theft setups, OEM connectors join security parts together. These parts include alarms, locks, and GPS trackers. The connectors help these systems talk well to stop thefts. Good materials make OEM connectors hard to mess with or damage from weather. This strength makes anti-theft systems more reliable, giving car owners peace of mind.

The World Automotive Connector Market Report shows how connected tech affects new car designs today. It highlights why OEM connectors matter for adding advanced systems smoothly into cars now more than ever.

Best Practices and safety tips

Installing and Keeping Up

How to Install Right

Installing OEM connectors the right way makes them last. Follow the maker's instructions carefully. Make sure connectors fit tightly so they don't come loose. Use proper tools to crimp and secure them well. This stops damage and keeps connections strong. Check that connectors are clean before putting them in. Clean ones lower the chance of electrical problems.

Checking Regularly

Regular checks keep OEM connectors working well. Look at connectors often for wear or damage signs. Watch for rust, which can block electricity and cause issues. Grease helps stop rust and short circuits from happening. Nye, a grease expert, says using grease is key to stopping shorts, especially in important parts like headlights. Regular checks save on repairs and make cars safer.

Fixing Usual Problems

Spotting Bad Connectors

Finding bad connectors fast stops bigger car troubles. Look for cracks or color changes as damage signs. Test with a multimeter to see if electricity flows right through it. If it doesn't pass, it might need replacing. Bad connectors can cause random electric problems, hurting car performance and safety.

Fixing Common Issues

Fixing OEM connector problems needs careful steps. If there's rust, clean it with cleaner and add grease after. For loose ones, re-crimp or replace them if needed. If overheated, find why too much current is flowing first. Fix these quickly to keep the car's electric system safe from dangers.

Future Trends in OEM Connectors

New Technology

Better Connector Materials

Car makers want better connector materials. They look for ones that don't rust or melt. These last longer and work well. Light materials make cars lighter, saving gas. As tech grows, new mixes make connectors stronger.

Smart Connectors and IoT

Smart connectors are a big step forward. They let cars talk to each other and roads. This helps with smart driving tools and self-driving cars. Smart connectors link to the Internet of Things (IoT). They share data fast about roads and car health.

Green Ideas

Earth-Friendly Connector Designs

Green concerns lead to earth-friendly designs. Makers use parts that can be recycled easily. This cuts waste and helps the planet. Green designs follow rules for nature safety.

Rules Affecting Connector Making

Rules shape how connectors are made. Governments set rules for safety and green actions. These rules change what is used to make connectors. Following them keeps cars safe and lessens pollution from making cars.

OEM connectors are important in car wiring. They help everything fit and work well together. As cars change, these connectors will get smarter and faster. They will also be better for the environment. The future of OEM connectors is bright. New ideas focus on making them lighter and smaller. They will also be made in ways that are good for nature. It's important to install and take care of them correctly to keep them working their best. Keeping up with new changes helps everyone use OEM connectors fully in today's cars.

See Also

Significance of Fakra Connectors in Automotive Sector

Essential Role of HSD Connectors in Auto Sector

Vitality of Fakra Auto Connectors in Contemporary Cars