Why OEM Automotive Electrical Connectors Matter

Automotive electrical connectors types play a crucial role in modern vehicles. They ensure stable and secure electric connections, enhancing the performance and safety of cars. The demand for these connectors is rapidly increasing, with a 5.8% annual growth projected until 2026. Among these types, OEM connectors stand out for meeting high standards and contributing to optimal vehicle performance. By providing robust connections, OEM connectors enhance the reliability of cars, making them indispensable in the automotive industry.

What are OEM Automotive Electrical Connectors?

Definition and Overview

Explanation of OEM connectors

OEM automotive electrical connectors are important in today's cars. They help different parts talk to each other and share power. These connectors are made to be strong and last long. They keep electric connections steady, which helps cars work well and stay reliable.

Importance in automotive systems

In car systems, OEM connectors are very important. They make sure that electric signals and power move smoothly between parts. This helps things like the engine, music system, and safety features work their best. Using good connectors lowers the chance of electric problems, making cars safer and better.

Types of OEM Connectors

Pin Connectors

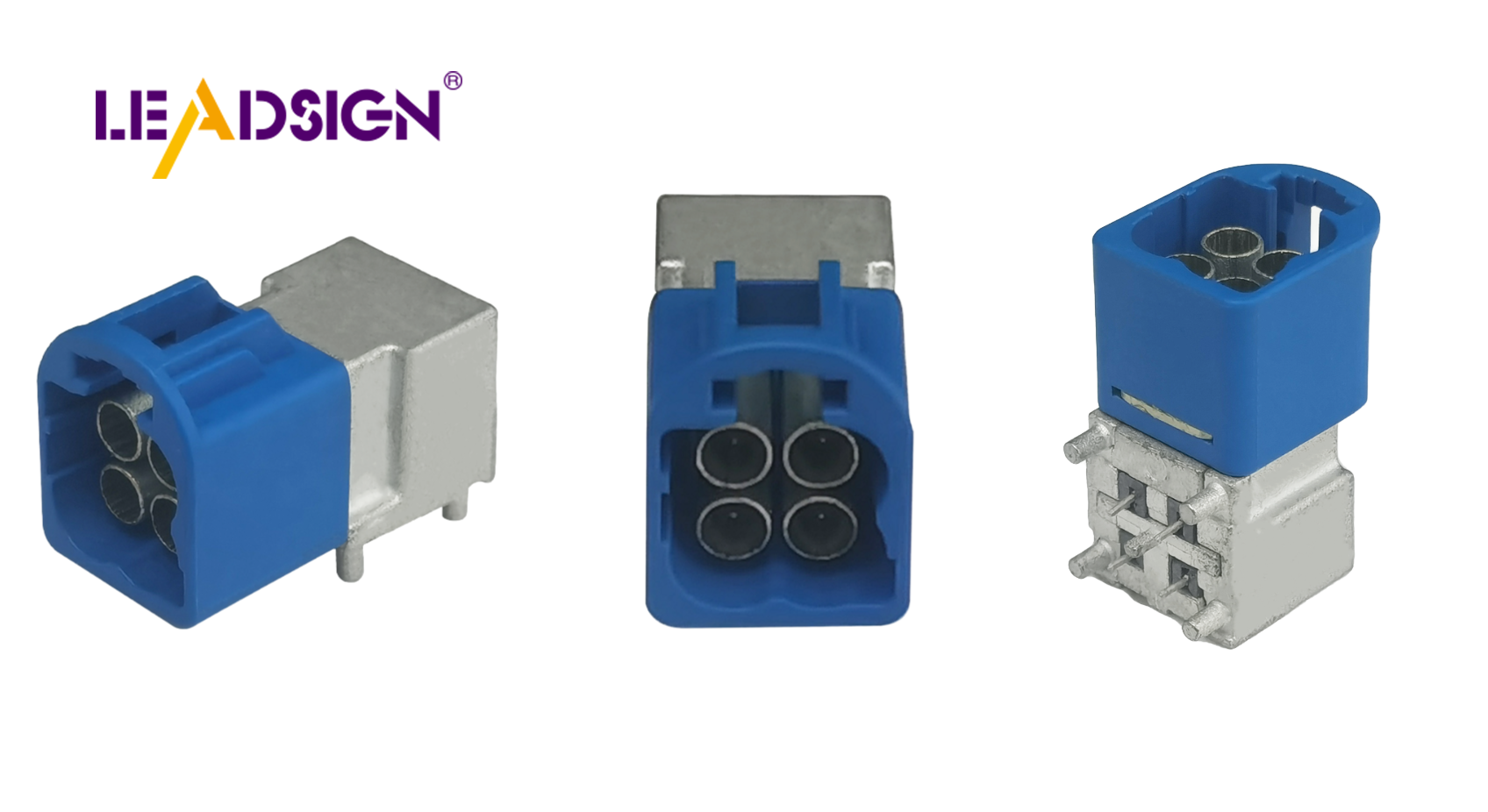

Pin connectors are common automotive electrical connectors types. They have metal pins that fit into matching holes for a tight connection. These are used in engines and other key places where strong connections matter.

Blade Connectors

Blade connectors are another popular kind with flat metal pieces that slide into slots. They connect wires quickly and easily. Their design makes it simple to put together or take apart, perfect for spots needing regular checks or changes.

HSD Connectors

HSD connectors handle fast data needs in cars. They're used in electronics like cameras and music systems. These support USB and Ethernet for quick data moves. Their tough build has locks for extra safety in hard conditions.

Why Do OEM Connectors Matter?

Benefits of Using OEM Connectors

Reliability and Durability

OEM connectors are very strong and reliable. They work well even in tough conditions. This helps cars run smoothly for a long time. These connectors keep electric parts working without problems. Using them means fewer repairs are needed. This saves money because the car parts last longer.

Compatibility with Vehicle Systems

OEM connectors fit perfectly with car systems. They match the original equipment, so they work right. This is important to keep the car's electric system safe. When everything fits well, parts talk better to each other. This makes the car work better and avoids problems from wrong parts.

Impact on Vehicle Performance

Electrical Efficiency

OEM connectors help cars use electricity better. They make sure power goes straight where it’s needed without wasting it. This helps things like lights and radios work well all the time. Good power flow also means better gas mileage and less pollution.

Safety Considerations

Safety is key in cars, and OEM connectors help a lot here too. They keep electric connections safe from short circuits or fires. Their strong build handles shakes and temperature changes in cars easily. By staying connected, they help safety features like airbags work properly.

OEM connectors are very important in cars. They keep electric connections steady and safe. This helps cars work well and stay safe. Let's see where they are used in cars.

In engines, OEM connectors are a must-have. They join parts like sensors and control units. This keeps the engine running smoothly. These connectors help send electric signals to check and control the engine. Strong connections make engines work better.

Infotainment systems need OEM connectors too. They connect screens, speakers, and maps together. This makes sure power and data move well, so entertainment works without stopping. Good connectors stop problems, making users happy.

Electric cars (EVs) use OEM connectors a lot. They link batteries, chargers, and motors safely. These handle lots of power for good energy flow as EVs become more popular.

Advanced Driver Assistance Systems (ADAS) make driving safer with OEM connectors linking sensors and cameras fast for quick decisions on the road.

Installation Guidelines

Careful Handling

When putting in OEM connectors, be careful. Technicians should handle them gently to avoid breaking the pins and sockets. If not handled right, it can cause bad connections and problems in the car's electric system. Using the right tools helps keep connectors strong and reliable.

Making Sure Connections Are Tight

Tight connections are key for OEM connectors to work well. Installers must make sure connectors are fully clicked in place. This stops loose or weak connections that can cause electric issues. A tight connection makes car parts work smoothly and safely.

Maintenance Tips

Regular Checks

Checking OEM connectors often helps find problems early. Technicians should look for wear, rust, or damage regularly. Finding issues early means fixing them before they get worse, keeping the electric system working well.

Cleaning and Looking After Them

Cleaning OEM connectors is important to keep them working well. Dust and water can mess up electric connections. By cleaning them properly, technicians stop rust and keep them waterproof and dustproof. This care makes connectors last longer, saving money over time.

By following these tips, users can get the most from OEM connectors, making sure their cars run safely and efficiently.

Future Thoughts for OEM Connectors

New Technology

Better Connector Designs

Car connectors are changing fast. Engineers want to make OEM connectors better. They try to make them smaller and work well. These new designs help cars by keeping connections strong. Using new materials, makers create connectors that handle tough weather and bumps.

Working with Smart Systems

Cars are getting smarter, needing better connectors. OEM connectors help parts like sensors talk well. This makes driving safer with real-time info. Their easy plug-in design fits smart systems easily.

Helping the Environment

Eco-Friendly Materials

Car makers care about the earth more now. They use green materials for connectors. These last longer and hurt the planet less. Choosing these helps keep high standards while being kind to nature.

Recycling Right

Recycling car connectors is important to save the earth. Makers have plans to recycle parts right. They break down old ones and reuse bits when they can. Good recycling cuts waste and helps a circular economy.

OEM connectors are better than others because they fit cars well and last long. Though they cost more at first, they're worth it for safety and reliability as tech grows and we care more about nature.

OEM car connectors are very important today. They help car parts talk to each other well. This makes cars work better and stay safe. Companies like Eigen make these connectors strong and reliable. As tech gets better, these connectors will be even more needed. They will help new car tech work right, keeping cars efficient and safe. The future of these connectors looks exciting with new ideas that will make car systems better, making them a must-have in the changing car world.

See Also

Significance of High-Speed Data Connectors in Auto Sector

The Significance of FAKRA Connectors in Contemporary Cars

The Value of FAKRA Connectors in Auto Sector

The Vital Role of FAKRA Connectors in Auto Uses

Boosting Data Transfer: The Significance of High-Speed Auto Connectors