Why Automotive Electrical Connectors Types Matter for Standards

Automotive electrical connectors types are crucial for modern vehicles, facilitating communication between various car components. These connectors must withstand harsh conditions such as high voltage and heat to ensure the vehicle remains safe and operational. High-voltage connectors can fail, impacting vehicle performance. Standards ensure these connectors are safe, functional, and compatible with different automotive systems. By adhering to these standards, manufacturers enhance vehicle quality and safety, underscoring the importance of automotive electrical connectors types in vehicle production.

Current Status of Automotive Electrical Connectors

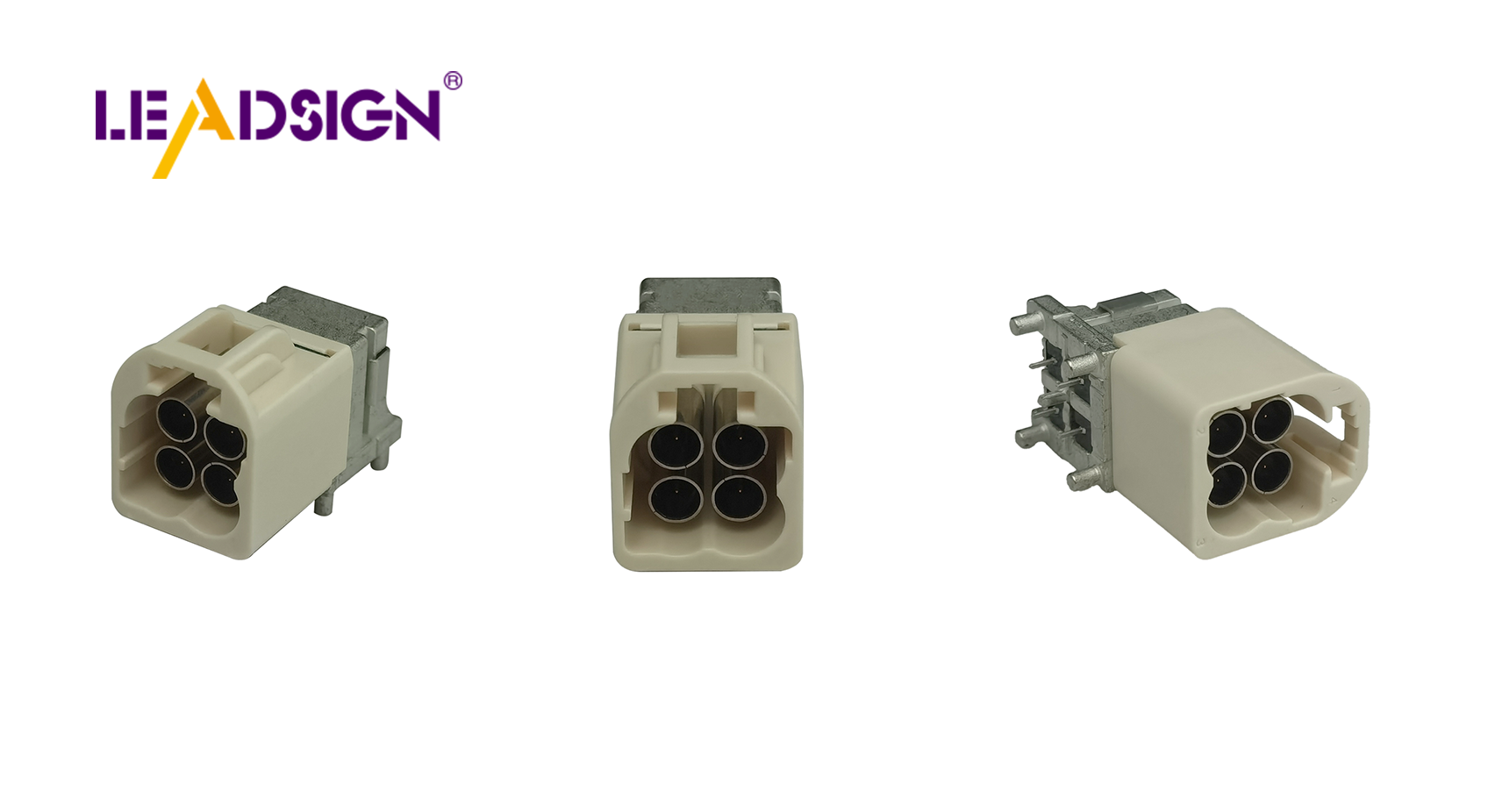

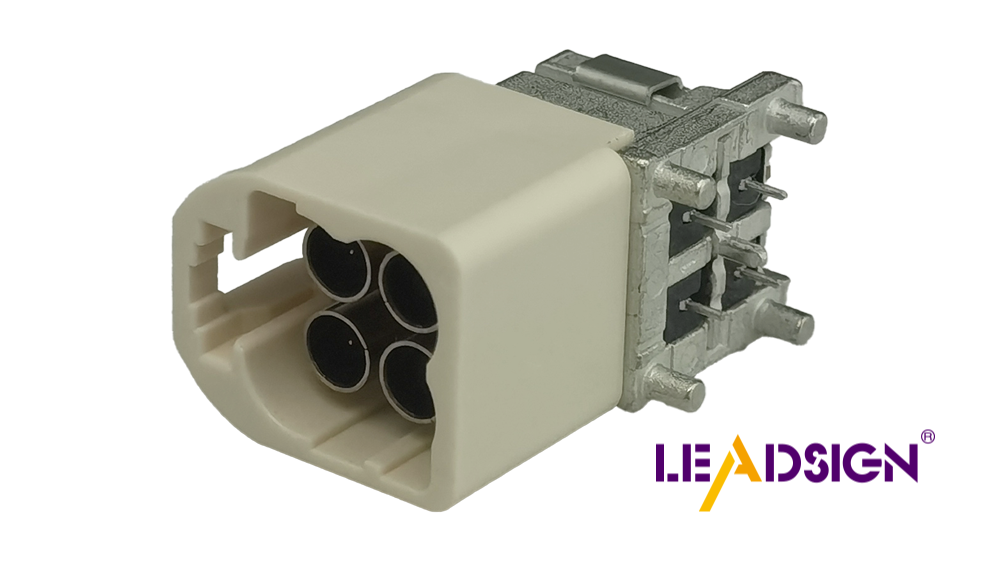

Automotive Electrical Connectors Types

Automotive electrical connectors types are very important for cars. They help different parts talk to each other, keeping the car working well and safely.

Blade Connectors

Blade connectors are key in circuits. They connect electric systems, helping power move and signals send. In cars, they work in engines, music players, and lights. They are easy to plug in and out, so many car makers like them.

Pin Connectors

Pin connectors, or pigtail connectors, handle lots of power. They are used in headlights and starters. These have colored ends that match wire colors. This makes putting them together simple and avoids mistakes, making sure they work well.

Butt Connectors

Butt connectors join two wires tightly. They are needed where wires must be joined in cars. By squeezing wires into them, a strong link is made. This is good when space is small but a firm connection is needed.

Market Trends

The car world changes fast, affecting how we use automotive electrical connectors types.

Increasing Demand for Electric Vehicles

More people like electric cars now which affects connector needs. Electric cars need special ones for high power use. As more buy these cars, makers create better connectors for them. This change helps new ideas grow in the market.

Advancements in Connector Technology

New tech makes better automotive electrical connectors types possible. New ones last longer, carry electricity better, and are smaller too. These help with complex new cars so they can face tough conditions while working best.

Performance Needs and Rules

Important Performance Signs

Car connectors need to meet certain signs to work well. These signs look at two things: how strong they are and how well they carry electricity.

Strength and Trust

Strength and trust are key for car connectors. They must handle tough things like hot or cold weather, shaking, and hits. Strong materials help them last long. Studies show dirt and damage often break connectors. Makers fix this by using stuff that doesn't wear out or rust, making them last longer.

Carrying electricity well

Carrying electricity well is also important. Connectors need to send signals without losing power. Good ones make sure the car's electric parts work right. Bad ones can lose signals, hurting the car's work. So, makers design connectors that keep good power flow even when it's hard.

Industry rules

Industry rules help make sure car connectors meet needed performance levels. These rules guide how to make safe, reliable connectors that fit with different car parts.

ISO Rules

The International Organization for Standardization (ISO) makes world rules for car connectors. These rules make sure they meet quality and safety needs. ISO looks at things like what they're made of, their shape, and tests done on them. By following these rules, makers can create good connectors for all places.

SAE Rules

The Society of Automotive Engineers (SAE) also sets rules for car connectors. SAE focuses on technical details and how well they should work in cars. These rules ensure they can handle tough conditions in cars. By sticking to SAE rules, makers ensure their connectors meet high performance and safety standards.

Future Trends and New Technology

New Ideas in Connector Design

New ideas in car connectors change how cars work. Designers make connectors that fit new car needs, keeping them strong and useful.

Making Connectors Smaller

Making connectors smaller is a big trend. Engineers try to shrink connectors but keep them working well. Small ones save space and fit more parts in cars. This is key for electric cars where space is tight. Using small connectors helps make better car designs.

Better Connection Features

Better connection features are important too. New cars need fast data links and strong networks. These help with cool tech like music systems and driving aids. With better connections, car connectors keep up with new tech changes.

Effects of New Tech

New tech greatly changes car connector design. As cars get smarter, connectors must change to support new systems.

Self-Driving Cars

Self-driving cars are a big change in the car world. They need smart electric systems to work safely. Car connectors must handle complex networks for self-driving tech. They ensure sensors, cameras, and controls talk well together.

IoT in Cars

The Internet of Things (IoT) makes cars connect with other devices better. IoT helps cars do more cool things for users. Car connectors must support these links for smooth data sharing and talking between systems.

Automotive electrical connectors are very important for cars. They help car parts talk to each other easily. Different types and rules keep cars safe and working well. Standards make sure all parts fit together, which is crucial worldwide. As tech gets better, we need connectors that follow strict rules more than ever. In the future, we'll see smaller and stronger connectors. These new ideas will help with things like electric cars and self-driving cars. This shows how important connector types and standards are in making cars better.

See Also

Significance of HSD Connectors within the Auto Sector

Fundamentals of HSD Connectors in Automotive Sector

Significance of Fakra Connectors within Auto Sector