Ensuring Longevity of Vehicle Connectors with Proper Maintenance

Vehicle connectors are important for your car's electrical systems. They keep parts like engine controls, airbags, and lights working well. Installing them correctly and checking them often stops problems. This prevents loose wires, rust, and power issues. Taking care of vehicle connectors makes them last longer. It also helps your car work better.

Key Takeaways

Regularly check and clean your vehicle connectors to prevent issues like corrosion and loose connections, ensuring your car's electrical systems function smoothly.

Use the right type of connectors for your vehicle's needs, considering factors like current ratings and environmental conditions to enhance durability and performance.

Implement proper installation techniques, such as using strain relief and protective coatings, to extend the lifespan of connectors and avoid costly repairs.

Understanding Vehicle Connectors

Types of Automotive Connectors

Car connectors come in different shapes for various vehicle needs. Each type has a job to keep connections working well. Here are some common types:

Crimp Connectors: These attach to wires by squeezing them tightly. Examples include Bullet, Spade, and Butt Connectors.

Heat Shrink Connectors: These seal tightly to block water, great for outdoor use.

Weather Pack Connectors: These handle tough conditions like heat, cold, and chemicals.

Deutsch Connectors: Strong and durable, they keep out dirt and water.

Molex Connectors: These are flexible and used in engines and lights.

USB Connectors: These connect phones and entertainment systems in cars.

Each connector type helps your car's electrical parts work well. For example, connectors like Deutsch and Weather Pack are key for systems needing many connections.

Functions of Auto Electrical Connectors in Vehicles

Car electrical connectors are important for safe and smooth driving. They link circuits to power important parts of your car. These connectors join systems like lights, engine controls, and radios to keep them working.

For example, multi-pin connectors join many circuits in engine sensors or controls. They let electricity flow so lights and speakers work properly. Some connectors, like CPA connectors, protect your car's electrical system.

Using the right connectors helps your car run safely, even in tough conditions.

Common Problems with Car Electrical Connectors

Car electrical connectors are crucial for your car's performance. However, they can develop problems over time. Knowing these issues helps you prevent expensive repairs.

Checking for Damage

You should check car connectors often for signs of damage. Common issues include:

Loose Connections: Shaking or bad installation can make connectors loose. This causes power problems.

Corrosion: Water exposure can weaken connectors, leading to power loss or failure.

Burnt Connectors: Too much heat from overuse can burn connectors. These need quick replacement.

Finding these problems early helps you replace connectors before they completely fail.

How the Environment Affects Connectors

Weather and surroundings can harm car connectors. Water, temperature changes, and shaking are common causes.

Rain, especially acidic rain, can rust connectors over time.

Saltwater makes rusting happen faster, especially near oceans.

Hot and cold weather makes materials expand and shrink, loosening connectors.

Driving vibrations can also weaken or move connectors.

To protect connectors, use materials made for tough conditions. Adding protective coatings can stop rust.

Problems from Loose Connections

Loose connectors often cause electrical problems in cars. These include:

Random failures, making electronic parts act strangely.

Higher fire risk from heat caused by loose wires.

Bad performance in systems like radios or engine controls.

Taking care of connectors keeps them working well. Replace damaged ones quickly to keep your car reliable.

Proper Installation Techniques for OEM Wiring Connectors

Getting Connectors and Wires Ready

Getting connectors and wires ready makes installation easier and better. First, gather tools like wire cutters, crimpers, and covers. Work in a clean, bright area to avoid mistakes.

Here are some tips to prepare connectors and wires:

Tips for Preparing Connectors and Wires | What They Do |

|---|---|

Makes connections work well. | |

Use correct folding methods | Stops damage and keeps them strong. |

Add protection and reduce strain | Prevents wear and tear. |

Secure connectors tightly | Keeps them stable and connected. |

Cut wire ends to the right length and remove the cover carefully. Use crimpers to attach terminals firmly. Place terminals into the connector, making sure they fit right. Test the system to check it works and look for any problems.

Making Sure Connections Are Strong

Strong connections help connectors last longer. Use good tools like heat shrink tubes, wire cutters, and connector covers. Keep wires neat to stop tangling or breaking.

Make sure terminals fit tightly in the connector. Use locks to keep them in place and avoid disconnections. Add strain relief and covers to protect the connection. These steps help connections handle shaking and tough conditions.

Avoiding Mistakes During Installation

Avoiding mistakes saves time and stops future problems. Follow these steps to do it right:

Check pins for rust or damage before starting.

Use tools made for car connectors to avoid harm.

Look for damaged wires to stop short circuits.

Test the system after installing to find issues early.

By following these steps, you can install connectors easily and keep your car's electrical system working well.

Maintenance Tips for Car Connectors

Cleaning and Checking Car Connectors

Taking care of car connectors starts with cleaning and checking. Dirt, rust, and water can make them work poorly over time. Follow these steps to keep them in good shape:

Use a small brush to clean off rust and dirt.

Spray electrical cleaner to remove grime completely.

Add grease to improve connections and block air and water.

Clean more often if you live in a humid place.

Make loops in cables to stop water from reaching connectors.

Checking connectors is just as important. Gently move the wires while the car is on. Watch for flickering lights or strange smells. These signs may mean your connectors have problems.

Keeping Connectors Safe from Rust and Water

Rust and water can damage car connectors easily. Protecting them helps them last longer. Try these tips:

Use strong materials like stainless steel for outdoor connectors.

Add grease after cleaning to keep out air and water.

Use seals like o-rings to block water from getting in.

Pick parts made for tough weather if used outside.

Check connectors often, especially in wet or salty areas.

Adding coatings and using weatherproof parts can make connectors stronger. These steps help them survive bad weather.

Using Coatings and Sealants

Coatings and sealants protect car connectors from damage. Different oils work for different conditions:

Oil Type | Temp Range | Works With Materials |

|---|---|---|

Petroleum | -20 to 100°C | Okay |

Synthetic Hydrocarbon | -60 to 125°C | Good |

Fluoroether (PFPE) | -80 to 250°C | Excellent |

Polyphenyl Ether (PPE) | 20 to 225°C | Good |

Pick an oil based on your car's needs. For example, synthetic hydrocarbon is good for most weather, while fluoroether is best for very hot or cold places. Adding these during cleaning or setup keeps connectors safe and working well.

Picking the Right OEM Automotive Connectors

Things to Think About for Fit and Strength

Choosing the right connectors keeps your car's electrical system working. You need to check a few things to match OEM systems and ensure they last.

Current and Voltage Ratings: Make sure they handle power safely.

Number of Contacts: Pick connectors with enough points for good signals.

Environmental Conditions: Use ones that resist heat, cold, and moisture.

Mechanical Features: Find connectors with locks to stop them from loosening.

Material: Plastic is good for light use; metal is for tough jobs.

OEM connectors are made for specific cars. They use strong materials to handle heat, water, and shaking, making them last longer.

Knowing Connector Ratings and Rules

Connector ratings help you pick the best ones for your car. These ratings show if they meet safety and performance needs.

Temperature Ratings (T1-T5): Show the range of temperatures they can handle.

Sealing Ratings (S1-S3): Tell how well they block dust and water.

Vibration Ratings (V1-V5): Check if they stay strong in shaky conditions.

Also, look for labels like TUV, CE, or UL. These prove the connectors are safe and strong, meeting your car's needs.

Choosing Strong Connectors for Special Uses

Good connectors make cars safer and easier to fix. They also work with new tech.

Factor | Why It Helps |

|---|---|

Stops overheating and keeps things safe. | |

Voltage rating | Prevents sparks and keeps systems safe. |

Environmental Conditions | Works well in bad weather. |

Mechanical factors | Stops wires from breaking or coming loose. |

Material | Makes connectors strong for different uses. |

OEM connectors are tested to work well. They are made for modern cars, helping them stay reliable and fit with OEM systems.

Installing and taking care of car connectors is very important. Simple steps, like using heat-shrink tubes or zip ties, can stop expensive repairs. Checking and testing connectors often helps them work well. This makes them last longer and keeps your car running better.

FAQ

How often should you check car connectors?

Check them every three months to find problems early. Regular checks can stop issues like rust or loose wires.

What tools are needed for connector care?

You need a brush, cleaner, and grease for maintenance. These tools help clean and protect your car's connectors.

Can any connector work for your car?

No, only use connectors that fit your car's needs. Wrong connectors can cause electrical problems or safety issues.

See Also

Boosting Data Transfer: Significance of Fast Automotive Connectors

Improving Vehicle Data Flow: Cutting-Edge Connectors and Wires

Increasing Performance Using HFM Connectors in Vehicles

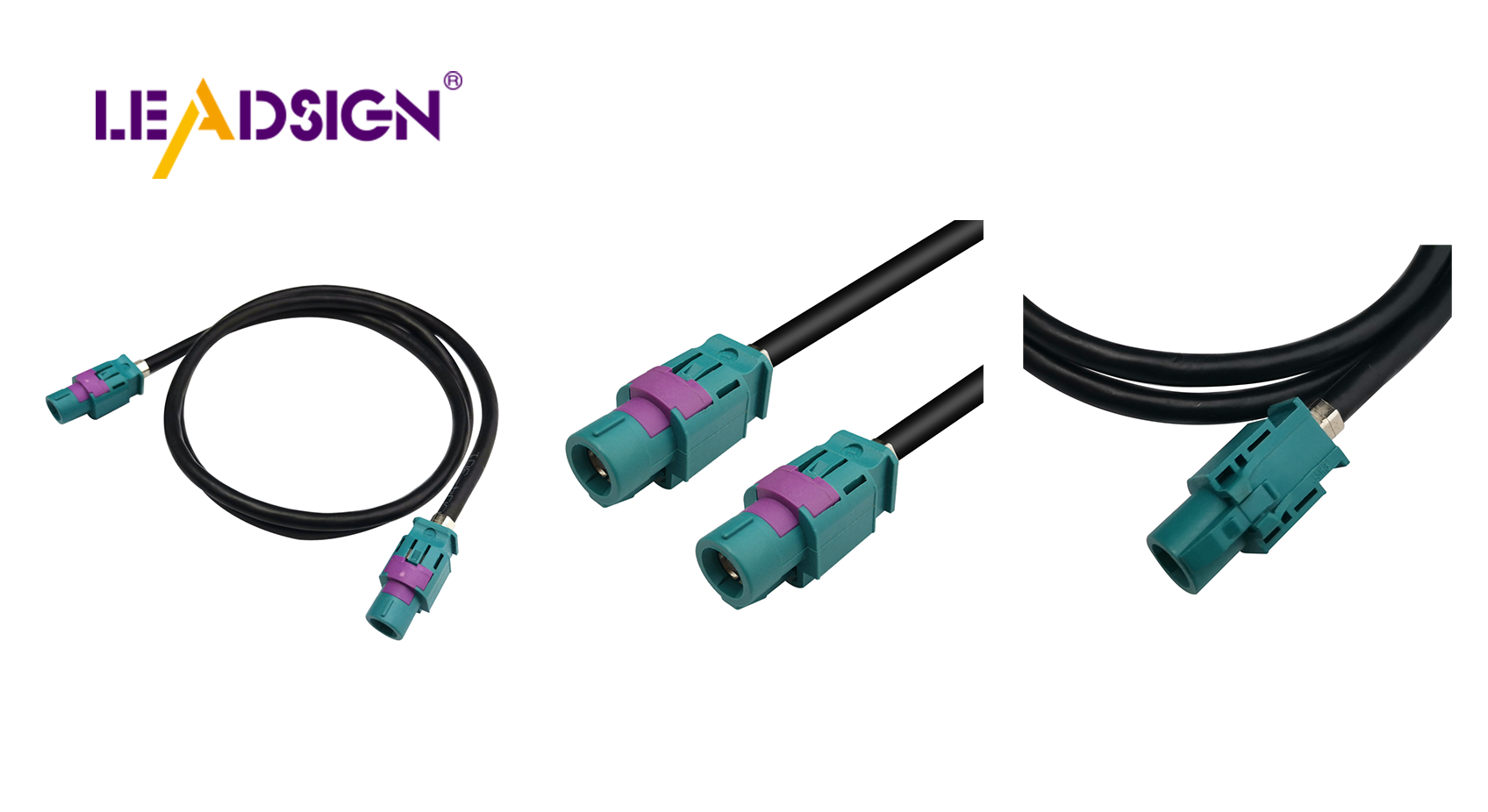

Significance of Fakra Connectors in Today's Automotive Technology