Everything You Need to Know About Vehicle Connectors for Optimal Performance

Vehicle connectors are important for your car to work well. They create safe electrical links between key parts like lights and brakes. Without good vehicle connectors, problems such as electrical issues or system breakdowns can occur. Using high-quality connectors and checking them regularly ensures they function properly. Taking care of vehicle connectors helps your car stay safe and operate more efficiently.

Key Takeaways

Vehicle connectors are essential for safe and efficient car operation, linking electrical systems like lights and brakes.

Regularly check and maintain connectors to prevent electrical issues and extend the lifespan of your vehicle's systems.

Choose the right type of connector based on your vehicle's needs, such as crimp, multi-pin, or high-voltage connectors for electric cars.

Use high-quality materials and certified connectors to ensure safety and reliability in automotive applications.

Proper installation is crucial; follow guidelines and use the right tools to avoid common mistakes that can lead to failures.

Weatherproof connectors protect against moisture and dirt, enhancing the durability of your vehicle's electrical systems.

Address any signs of connector issues, such as rust or loose connections, promptly to maintain optimal vehicle performance.

Understanding Vehicle Connectors

What Are Vehicle Connectors?

Vehicle connectors are key parts that link electrical systems in cars. They help send power and data between parts like lights and brakes. These connectors come in many shapes and sizes to fit different car needs.

Modern cars depend on complex electrical systems to work well. Without good connectors, these systems can't share information properly. For instance, auto electrical connectors join sensors, cameras, and control units. This helps your car work as it should, whether it's gas-powered or electric.

Essen Deinki, an expert in car design, says, "Modern cars have advanced electrical systems. Connectors help these systems work together, improving how the car runs."

Why Are Vehicle Connectors Important in Cars?

Car connectors are crucial for keeping your vehicle safe and working. They make sure all electrical links are strong and reliable, avoiding problems. Weak connectors can cause big issues like system failures or even fires.

Strong electrical connectors are even more important in electric cars. These cars need precise and tough connectors for their high-voltage systems. Good connectors improve safety by stopping short circuits and other dangers.

Also, high-quality auto electrical connectors reduce damage over time. This helps your car's electrical systems last longer. Checking and maintaining connectors often can save money on repairs and keep your car running smoothly.

Types of Vehicle Connectors

Vehicle connectors have different designs for specific car needs. Knowing the types helps you pick the right one for your car's electrical system.

Crimp Connectors

Crimp connectors are popular because they are strong and easy to use. They work by squeezing the connector tightly around the wire. This creates a secure link that resists shaking and movement. These connectors are great for areas like engines where strength is needed.

Crimp connectors perform well in tough conditions. They are often used in automotive wiring harness systems to keep wires connected. For wiring harness repair, crimp connectors are a fast and reliable choice. They hold wires tightly, even with constant vibrations, ensuring they last a long time.

Multi-Pin Connectors

Multi-pin connectors are important for cars with advanced electrical systems. They let many wires connect in one place, keeping things neat and organized. You can find them in dashboards, lights, and engine systems.

These connectors make handling multiple wires easier and reduce mistakes. They are helpful in auto electrical connectors, where accuracy is key. Multi-pin connectors improve how your car works by helping parts communicate smoothly.

Tip: Check multi-pin connectors often for damage to keep them working well.

High-Voltage Connectors

High-voltage connectors are crucial for electric vehicles and high-power systems. They safely move power between parts like batteries, motors, and chargers. These connectors are built to handle high energy levels without problems.

Choose high-voltage connectors made for strong systems to stay safe. They help your car's electrical parts last longer and work better. Using good high-voltage connectors prevents overheating and short circuits.

Did You Know? High-voltage connectors are also used in telecom for heavy power needs.

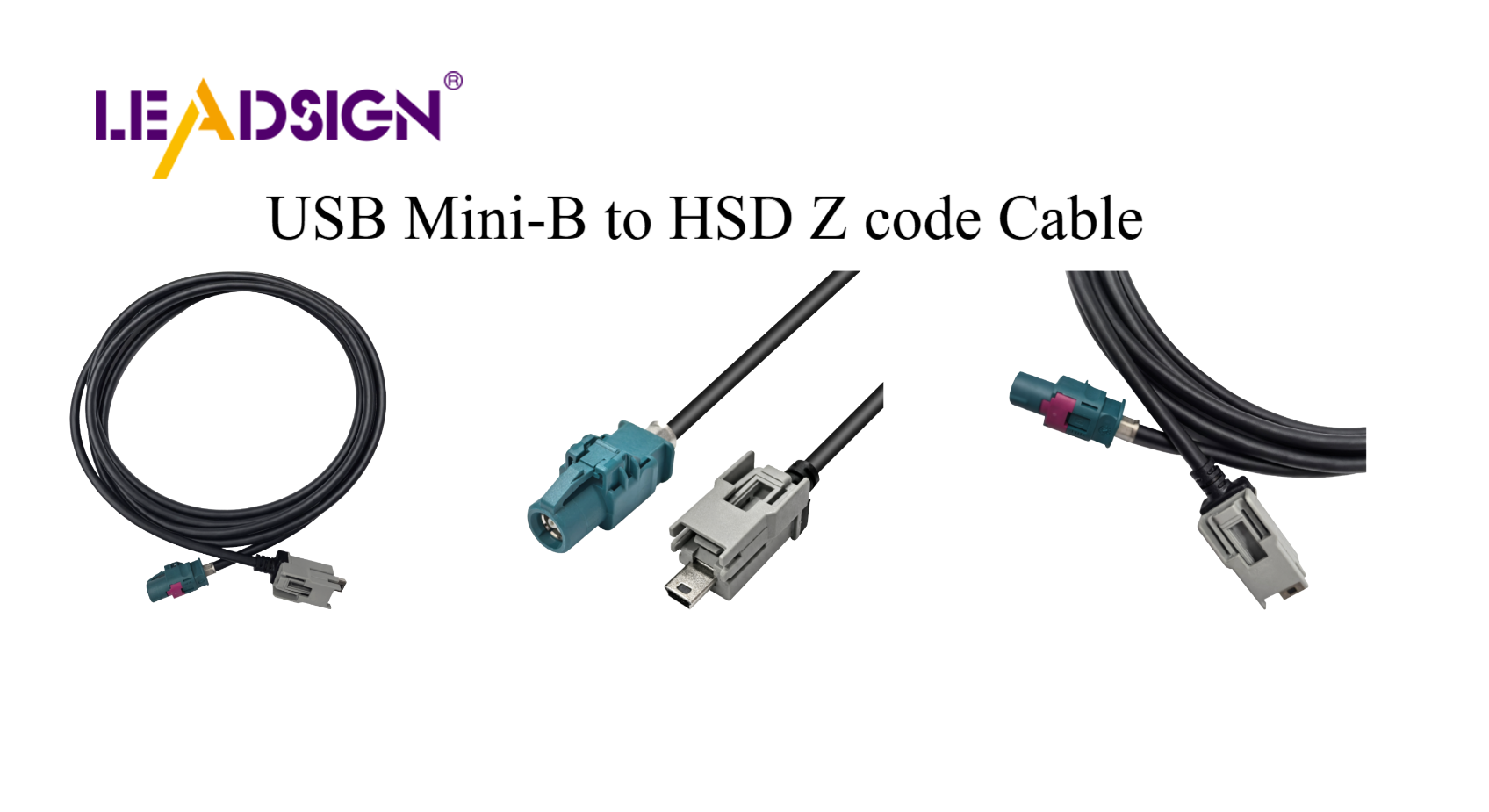

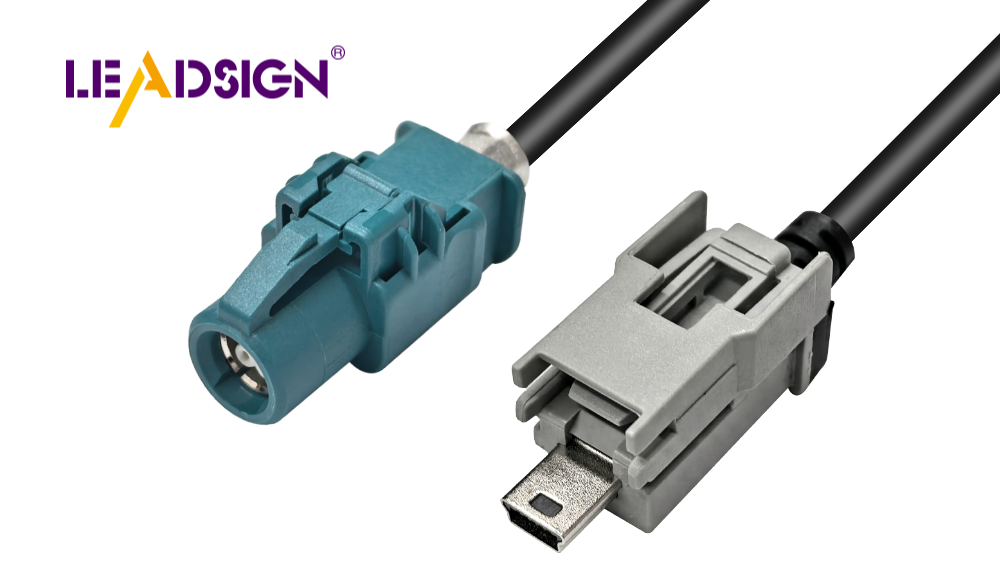

HSD Connectors for High-Speed Data Transmission

HSD connectors are important for cars needing fast data sharing. They help systems like cameras, sensors, and screens work together smoothly. By handling fast data, HSD connectors improve advanced car features.

These connectors are made to be strong and reliable. They have:

Primary and secondary locks to keep connections secure.

Crimp connections for steady and firm links.

High cable retention force to handle shaking.

Coding efficiency to avoid wrong connections.

HSD connectors are great for car electronics like infotainment systems. They support tools like USB 3.0, Ethernet, and LVDS for smooth data flow. Using HSD connectors helps your car's systems work better together.

Pro Tip: Check HSD connectors often for damage to keep them working well.

Specialized Connectors for Automotive Applications

Specialized connectors are made for specific car needs. They help cars run safely and efficiently. These connectors are used for power, data, or tough conditions.

Examples of specialized connectors include:

High-voltage connectors: These are key for electric cars. They safely move power between batteries, motors, and chargers. They handle high energy levels and last in tough conditions.

Multi-pin connectors: These group many wires into one unit. They are used in dashboards and engines to reduce mistakes and improve reliability.

Crimp connectors: These are strong against vibrations. They tightly hold wires, making them perfect for engines.

Specialized connectors are very useful for modern cars. They make electrical systems more reliable and work with new technologies. Picking the right connector can make your car last longer and perform better.

Did You Know? Specialized connectors can handle extreme heat, cold, and moisture, making them great for outdoor use.

Picking the Best Vehicle Connectors

Choosing the right electrical connectors is very important for safety. Wrong connectors can cause failures, expensive fixes, or even dangers. Focus on fit, strength, and certifications to make smart choices.

Matching with Vehicle Systems

Make sure the connectors match your car's systems. Cars have different setups, so not all connectors will work. For example, auto electrical connectors in regular cars won't suit electric cars. Electric cars need special high-voltage connectors.

Think about what your car parts need. For example, connectors in an automotive wiring harness must match the wiring and voltage. Using the wrong ones can stop power or data flow, causing problems. Always check your car's needs and match them to the connector's features.

Tip: Check your car manual or ask a mechanic to confirm fit before buying.

Strength and Material Quality

Good-quality connectors last longer and work better. They handle tough conditions like heat, water, and shaking. This is very important for automotive applications, where conditions can be rough.

Pick connectors made from strong materials like rust-proof metals or tough plastics. These materials keep connectors working well over time. For example, HSD connectors are strong and hold cables tightly, making them great for cars. Strong connectors lower the chance of problems and reduce replacements.

Did You Know? Strong connectors protect your car's systems from damage caused by weather or wear.

Certifications and Safety Standards

Certifications show that connectors meet safety and quality rules. Choose connectors with trusted certifications like ISO or SAE. These prove the connectors were tested and are safe for automotive applications.

For example, HSD connectors in systems like ADAS or Ethernet follow strict rules for smooth data sharing. Certified connectors also prevent problems like overheating or short circuits. Picking certified connectors ensures they are safe and reliable.

Pro Tip: Always check for certifications to make sure connectors meet your car's needs.

Environmental Factors (e.g., weather protection)

When picking vehicle connectors, think about how they handle weather. Cars face tough conditions like rain, snow, heat, and dust. Using connectors that resist these keeps your car safe and reliable.

Weatherproof connectors stop moisture, dirt, and heat from causing damage. They use strong materials and seals to block water or debris. For example, rubber gaskets or silicone seals keep moisture out. This lowers the chance of rust or short circuits. These features are key for outdoor parts like headlights or undercarriage wires.

Tip: Check connectors for cracks or broken seals often. Even small gaps let in water and cause issues.

Good weatherproof connectors also handle temperature changes well. In hot areas, heat-resistant plastics or metals stop melting or bending. In cold places, freeze-proof connectors stay strong and don’t crack. This helps your car work well in any weather.

For advanced systems like ADAS or Ethernet, HSD connectors are great in bad conditions. They send data fast without problems, even in harsh weather. Their tough design includes crimp links and strong cable grips, making them good for power and data.

Did You Know? HSD connectors are used in systems like CAN and LVDS because they handle rough environments well.

To keep connectors working long, pick ones with water and dust ratings like IP67 or IP68. These show they meet rules for strength and safety.

Pro Tip: Keep extra connectors in a clean, dry spot to avoid damage.

By focusing on weather protection, you can make your car’s electrical parts last longer. Weatherproof connectors protect against outside damage and improve your car’s safety and performance.

Installing Vehicle Connectors

Installing vehicle connectors the right way keeps your car safe. It also helps your car's electrical systems work well and last longer. Using proper tools and steps avoids problems and extends connector life.

Tools and Equipment Needed

Before starting, gather all the tools you need. Having the right tools makes the job easier and faster. Here’s what you’ll need:

Wire strippers: To remove wire covers without harming the wires.

Crimping tool: To tightly attach crimp connectors to wires.

Screwdrivers: To loosen or tighten screws on some connectors.

Heat shrink tubing: To protect connections from dirt and water.

Multimeter: To check if the connection works properly.

Electrical tape: To wrap and secure loose wires.

Pro Tip: Use good-quality tools to avoid damaging wires or connectors.

Step-by-Step Installation Guide

Installing connectors needs care and accuracy. Follow these steps to make sure the connection is strong and works well.

Preparing the Wires and Connectors

Check the wires: Look for damage like cuts or rust. Replace bad wires.

Strip the wires: Remove about 1/4 inch of the wire cover. Make sure the exposed wire is clean.

Clean the connectors: Ensure the connectors match your car's system. Wipe off any dust or dirt.

Tip: Confirm the connector type fits your car's needs, like crimp or multi-pin.

Securing the Connection

Insert the wire: Push the bare wire into the connector until it fits well.

Crimp the connector: Use a crimping tool to lock the wire in place. Press evenly to avoid damage.

Add protection: Slide heat shrink tubing over the connection. Use heat to seal it against dirt and water.

Did You Know? Crimp connectors are strong and handle vibrations well in cars.

Testing the Connection

Test with a multimeter: Check the connection for proper voltage and flow.

Inspect the connection: Look for loose wires or gaps. Fix them if needed.

Secure the wires: Wrap wires with electrical tape to keep them in place.

Pro Tip: Always test connections before finishing to avoid future problems.

Common Installation Mistakes to Avoid

Avoiding mistakes saves time and prevents expensive fixes. Here are common errors and how to avoid them:

Wrong connector type: Make sure the connector fits your car's system. For example, electric cars need high-voltage connectors.

Bad wire stripping: Removing too much or too little cover weakens the connection. Use a wire stripper for accuracy.

Skipping testing: Not testing can hide problems. Always use a multimeter to check.

Over-tightening or under-tightening: Too much force can break connectors. Too little can cause loose wires.

Tip: Follow the maker's instructions to tighten connectors correctly.

By following these steps and avoiding errors, you can install vehicle connectors successfully. Proper installation improves your car's safety and keeps its electrical systems working well.

Taking Care of Vehicle Connectors

Keeping vehicle connectors in good shape helps them last longer. Simple steps can keep your car's electrical parts working well and save money on repairs.

Checking and Cleaning Regularly

Check your connectors often to find any problems early. Look for cracks, faded colors, or loose wires. Focus on areas like under the car or near the engine, where damage happens more.

Clean connectors with a soft brush or air to remove dirt. For tough grime, use special electrical cleaners. Don’t use water or regular cleaners, as they can harm the connectors. Clean connectors stop dirt from causing electrical issues.

Tip: Check your connectors every three months to avoid big problems.

Stopping Rust and Corrosion

Rust is a common problem for electrical connectors. Wetness, salt, and chemicals can cause rust, making connectors weak. Keep connectors dry and safe from these elements to avoid rust.

Use weatherproof connectors with seals to block water and dirt. Add a small amount of grease to the pins to protect them. If you see rust, clean it quickly with a rust remover to stop it from spreading.

Did You Know? Connectors with IP67 or IP68 ratings are great for wet or dusty places.

Keeping Connections Tight

Loose connectors can stop electricity from flowing properly. This can cause systems to fail. Check that all connectors are tight and wires are secure. Gently pull wires to ensure they don’t come loose. Tighten any loose ones with the right tools.

For connectors in vibrating areas, like engines, pick ones with strong cable grips. These stay tight even when the car shakes. Check these spots often to make sure everything stays connected.

Pro Tip: Don’t tighten connectors too much, as this can break them. Follow the maker’s instructions for best results.

By doing these simple tasks, you can make your vehicle connectors last longer. Regular checks, cleaning, and care keep your car’s electrical parts safe and working well.

Replacing Broken Connectors

Fixing broken connectors keeps your car's electrical parts working well. Broken connectors can stop power, cause problems, or even be unsafe. Follow these steps to replace them and keep things running smoothly.

1. Find the Broken Connector

Check your car's connectors for damage. Look for cracks, rust, or faded colors. Focus on areas like under the car or near the engine. Broken connectors may have loose pins, melted parts, or rust. Finding the problem early stops bigger issues later.

Tip: Use connectors with IP67 or IP68 ratings. These handle water and dust better in tough spots.

2. Get the Right Tools

Before starting, gather tools to make the job easier. Using proper tools helps create a strong connection. You’ll need:

Wire strippers to remove wire covers.

Crimping tools to attach new connectors.

Heat shrink tubing to seal connections.

Multimeters to test if it works.

Electrical tape to secure wires.

Pro Tip: Good tools prevent damage to wires or connectors during fixing.

3. Take Out the Broken Connector

Carefully remove the broken connector from the wires. Don’t pull the wires directly, as this can break them. Use a screwdriver or release tool if needed. After removing, check the wires for rust or damage. Cut and strip wires to expose clean ends if necessary.

Did You Know? Metal connectors last longer in tough conditions than plastic ones.

4. Put in the New Connector

Pick a connector that fits your car’s needs. Make sure it matches the wire size, voltage, and conditions. Follow these steps to install it:

Push the stripped wire into the connector.

Use a crimping tool to lock it tightly.

Cover the connection with heat shrink tubing and seal it with heat.

Test it with a multimeter to ensure it works.

Tip: For electric cars, use high-voltage connectors that handle tough conditions like water and chemicals.

5. Check and Secure the Connection

After installing, test the connector to see if it works. Use a multimeter to check voltage and signals. Make sure the connection is tight and stable. Wrap wires with tape or ties to keep them neat and safe.

Scientific Research Findings: Regular checks and care for connectors stop wear and keep them working longer.

Replacing broken connectors makes your car safer and more reliable. By following these steps, you can fix your car’s electrical system and avoid expensive repairs later.

Troubleshooting Common Issues

Vehicle connectors can have problems as they age. These issues can affect how your car works. Finding and fixing them early keeps your car's electrical systems reliable. Below are ways to spot and fix common connector problems.

Spotting Connector Problems

Loose Connections

Loose connections can cause electrical parts to fail sometimes. You might see flickering lights or sensors not working right. Power may also stop and start. This happens when connectors are not tight or engine vibrations loosen them. Check your automotive connectors often to find loose ones before bigger problems occur.

Rust or Corrosion

Rust or corrosion happens in wet or salty areas. Look for green or white buildup on connectors. You may also notice trouble connecting or total system failure. Corroded connectors block electricity flow, so fixing them is very important for cars.

Electrical Issues

Electrical problems often come from broken or bad-quality connectors. Signs include headlights not working, dashboard errors, or ignition trouble. In electric cars, bad connectors can harm high-voltage systems and be unsafe. Spotting these issues early can save you from expensive repairs.

Fixing Common Problems

Cleaning Rusty Connectors

Cleaning rusty connectors helps them work again. Follow these steps:

Turn off the power to stay safe.

Use a soft brush or sandpaper to clean off rust.

Spray electrical cleaner to remove tough buildup.

Dry the connectors and add a protective layer to stop future rust.

Tip: For an automotive wiring harness, make sure all wires are clean before putting them back together.

Replacing Broken Connectors

If cleaning doesn’t help, replace the connector. First, find the broken one. Use tools like wire strippers and crimpers to remove it. Attach a new connector that matches your car’s system. For electric cars, use high-voltage auto electrical connectors.

Pro Tip: If unsure, ask a mechanic for help. Experts like EZ Connector suggest professional installation for best results.

Installing Correctly

Good installation stops many problems. Use the right tools and follow the maker’s instructions. Tighten connectors well to avoid loose ones. Test with a multimeter to ensure everything works. For complex systems like an automotive wiring harness, check each connection carefully.

Did You Know? Bad installation can cause repeated problems, so it’s important to do it right.

Fixing these issues helps your vehicle connectors last longer. Regular checks and quick fixes keep your car running safely and smoothly.

Vehicle connectors are important for keeping your car safe and working well. Using good-quality connectors lowers the chance of electrical problems. It also helps your car's systems last longer. Installing them correctly and checking them often can stop expensive fixes. Look for problems early and fix them quickly during inspections. Clean and secure connectors work better and keep your car running smoothly. This is true for both regular and electric cars. Taking care of connectors improves how your car works and protects your money over time.

FAQ

What are automotive connectors, and why are they important?

Automotive connectors link electrical parts in vehicles. They help electricity flow between systems like lights and sensors. Without good connectors, your car might stop working or need costly repairs. High-quality connectors make your car safer and more reliable.

Quick Fact: Modern cars use advanced connectors for electronics like screens and safety tools.

How do I choose the right connector for my vehicle?

To pick the right connector, think about these points:

Compatibility: Make sure it fits your car's system.

Durability: Choose materials that resist rust, heat, and shaking.

Pin Density: More pins allow more connections and upgrades.

Certifications: Look for safety standards like ISO or SAE.

Pro Tip: High-density connectors handle power, signals, and data all at once.

Can I use the same connectors for electric and gas-powered vehicles?

No, electric cars need special connectors. EVs use high-voltage connectors to move power between batteries and motors. These connectors are made for high energy levels. Gas cars use regular connectors for lower power needs.

Did You Know? High-voltage connectors are small but strong, perfect for tight spaces in EVs.

How often should I inspect my vehicle connectors?

Check your connectors every three months. Regular checks help find loose wires, rust, or damage. Focus on areas like under the car or near the engine.

Tip: Clean connectors during checks to stop dirt and rust.

What tools do I need to install or replace connectors?

You’ll need these tools:

Wire strippers to remove wire covers.

Crimping tools to secure wires.

Heat shrink tubing to block moisture.

Multimeters to test connections.

Electrical tape to hold wires in place.

Pro Tip: Use good tools to avoid damaging wires or connectors.

How can I prevent rust and corrosion on connectors?

Use weatherproof connectors with seals to block water and dirt. Add a little grease to the pins for extra protection. If you see rust, clean it quickly and add a protective layer.

Quick Fact: Connectors with IP67 or IP68 ratings resist water and dust well.

What are the signs of a faulty connector?

Watch for these signs:

Flickering lights or electrical problems.

Rust or discoloration on the connector.

Loose wires or weak connections.

Dashboard errors or ignition trouble.

Tip: Fix these problems quickly to avoid bigger issues.

Can I repair a broken connector, or should I replace it?

You can fix small problems like loose wires or light rust. For big damage, like cracks or melted parts, replace the connector. Always use one that matches your car's needs.

Pro Tip: For electric cars, use certified high-voltage connectors for safety.

Are high-density connectors worth the investment?

Yes, high-density connectors are very useful:

They connect many parts in a small space.

They offer backups for safety.

They prepare your car for future upgrades.

Did You Know? High-density connectors are key for systems like ADAS and Ethernet in modern cars.

Why is proper installation crucial for vehicle connectors?

Proper installation keeps connections safe and strong. Bad installation can cause loose wires, failures, or even fires. Always follow the maker’s instructions and use the right tools.

Tip: Test connections with a multimeter to ensure they work.

By learning these FAQs, you can take better care of your vehicle connectors. Regular checks and correct installation will keep your car safe and running well.

See Also

Improving Vehicle Data Flow With Innovative Connectors And Cables

Boosting Data Transfer: Significance of Fast Automotive Connectors

Fakra Connectors: Essential Components for Today's Vehicles