Mastering Vehicle Connectors Installation for Automotive Systems

Vehicle connectors are important in vehicle electrical systems. They help parts communicate well for smooth working. Knowing how to install them makes vehicles safer and better. It also saves money by avoiding future problems. Learning the right steps helps you make strong and good connections in any vehicle project.

Key Takeaways

Using the right tools, like wire strippers and crimping tools, is essential for making strong and reliable connections in vehicle electrical systems.

Regularly checking and cleaning vehicle connectors can prevent rust and ensure optimal performance, helping to avoid costly repairs in the future.

Proper installation steps, including sealing connections and testing with a multimeter, are crucial for maintaining safety and functionality in automotive systems.

Tools and Materials for Vehicle Connectors Installation

Tools You Need

To install connectors, you need the right tools. Use a wire stripper to remove wire covers without harm. A crimping tool helps make strong wire connections. A multimeter checks if electricity flows correctly. A heat gun shrinks tubing to protect wires. Keep screwdrivers and pliers nearby for small fixes. These tools make your work easier and more accurate.

Materials That Last

Pick strong materials to make connectors last longer. Copper alloys are great because they carry electricity well and don’t rust. Special plastics like PEEK handle heat and stay strong in engines. Gold or nickel coatings stop wear and keep connections working. Lubricants help parts move smoothly and prevent rust. These materials make connectors work better and last longer.

Staying Safe

Safety is very important when installing connectors. Wear gloves to avoid electric shocks. Use safety glasses to protect your eyes. Work in a bright area to see clearly. Check your tools to make sure they work well. Always disconnect the car battery before starting. These steps keep you safe and help you do a good job.

Step-by-Step Guide to Installing Vehicle Connectors

Getting Ready and Finding the Right Connectors

Before starting, set up your workspace and find the connectors. Follow these steps for an easy process:

Use a wire stripper to remove the wire cover. This shows the metal inside for connecting.

Use a crimping tool to attach male pins to wires. This keeps them tightly connected.

Add a seal to the wires. This keeps out water and dirt.

Match the terminals to the correct connectors. Make sure they are tight to avoid loose connections.

Keep your tools and materials in a clean, bright space. Label the connectors to match their terminals. This helps avoid mistakes and saves time.

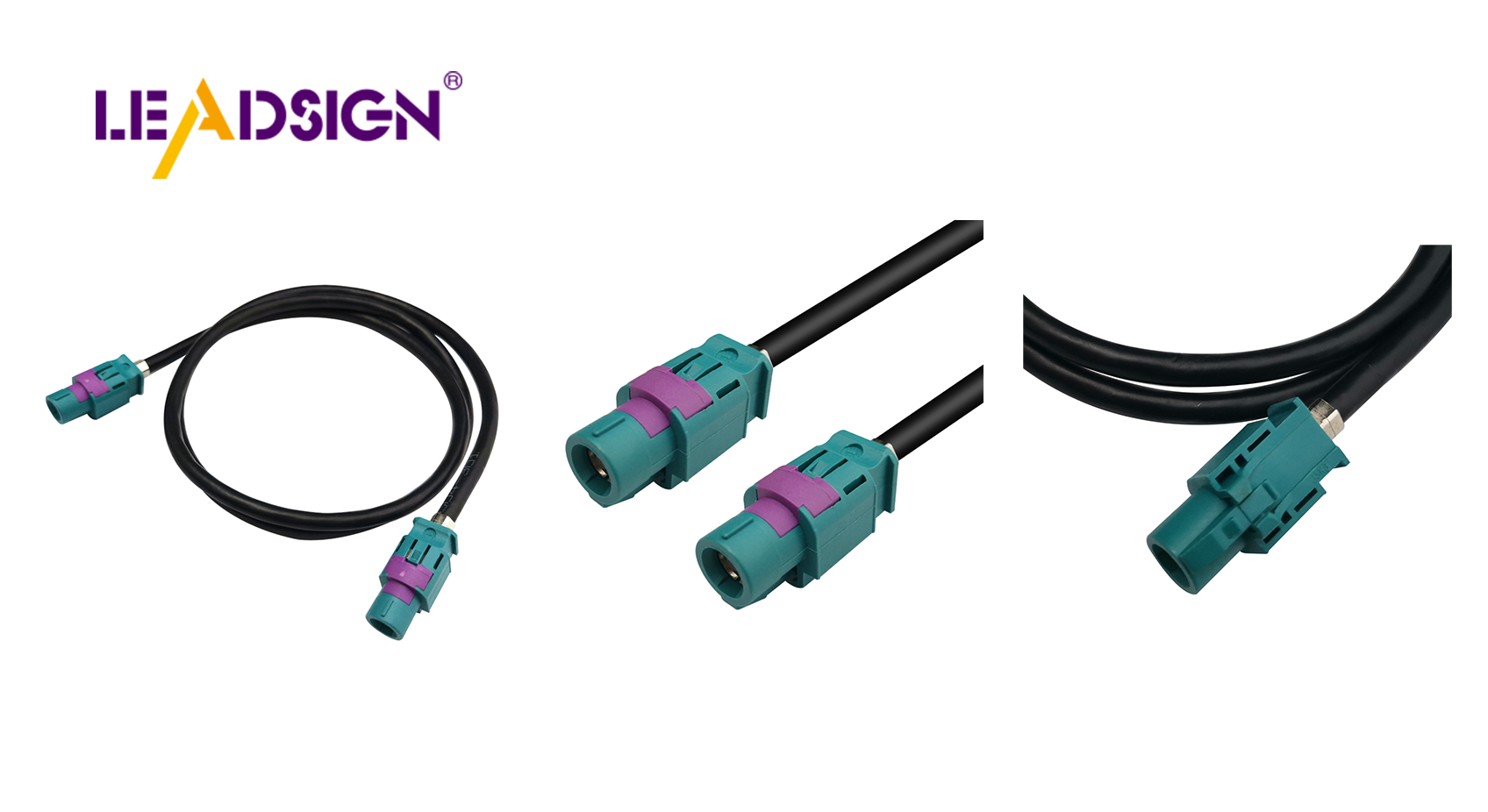

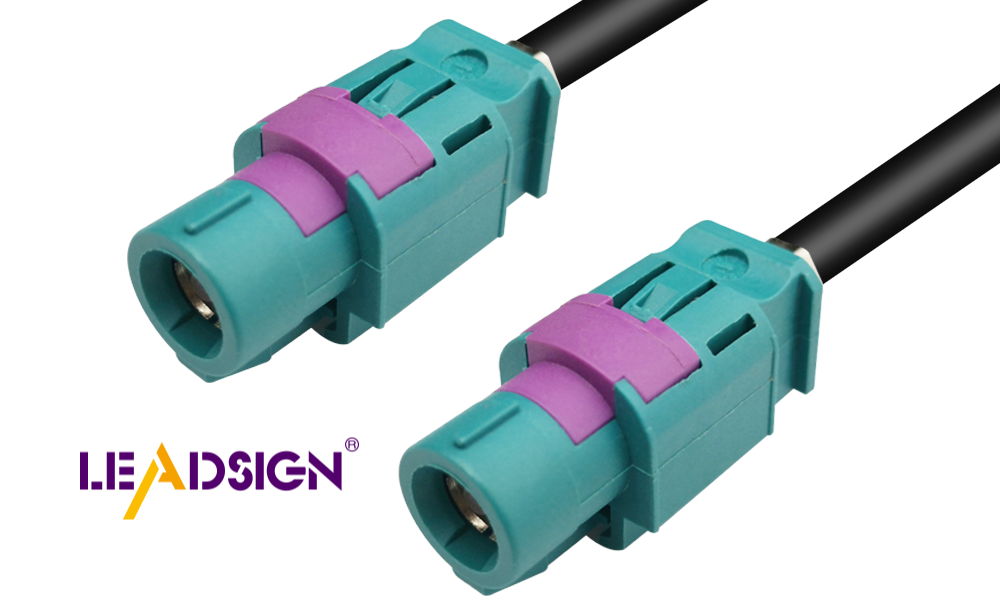

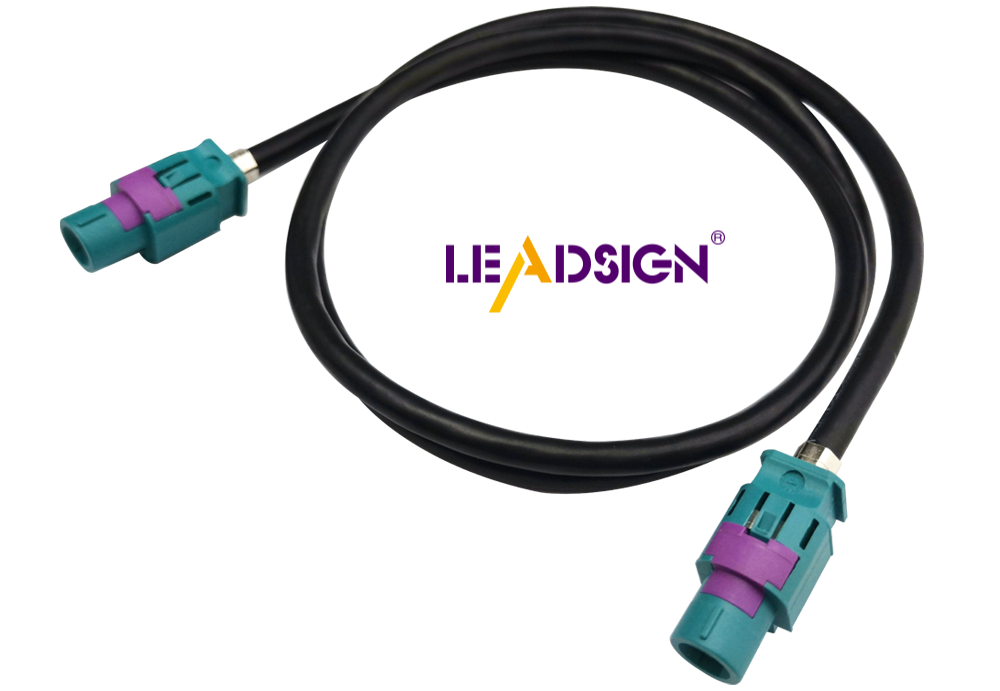

Tip: Check the type of connector before starting. For example, HSD connectors work well for car audio or charging systems.

Wiring and Crimping Steps

Good wiring and crimping make strong connections. First, cut the wires to the right length. Carefully strip the wire cover. Use a crimping tool with ratchets to press firmly. This stops damage from pressing too hard.

Cover the crimped part with heat-shrink tubing for safety. Use a heat gun to shrink it tightly. Tie the wires with zip ties to keep them neat. Keep wires away from sharp edges or hot areas to protect them.

Note: Strong crimping stops gas or water from getting in. This helps prevent rust over time.

Securing and Checking Connections

After installing, secure the connectors in place. Use clamps or grommets to hold wires tightly. This stops vibrations from loosening them. Test the connections with a multimeter. Make sure electricity flows without breaks.

Look at the connectors to check for damage or loose parts. Fix any problems right away to avoid future issues. Testing makes sure your work is safe and works well.

Reminder: Reconnect the car battery after finishing and testing everything.

Troubleshooting and Maintenance of Vehicle Connectors

Fixing Loose or Bad Connections

Loose or bad connections can cause electrical problems in cars. First, check the connectors for damage or if they are not lined up. If a connection is loose, tighten it gently with pliers or a screwdriver. For bad connections, take out the connector and check the wires. Fix damaged wires by stripping and crimping them again. Always use a multimeter to test if electricity flows properly.

If the problem continues, look at the connector housing. Dirt or small particles inside can block the connection. Clean it with a soft brush or compressed air. For advanced systems like those with HSD connectors, make sure the terminals match correctly to avoid mistakes.

Tip: Label your connectors when installing to make future fixes easier.

Stopping and Fixing Rust

Rust is a common problem for vehicle connectors. Stop it by using dielectric grease on connectors and terminals. This grease keeps water out. Check battery terminals often and clean them with baking soda if rust appears. Use a spray to protect parts from bad weather.

To lower rust risks, park your car in a garage to avoid road salt. Wash your car often to remove salt and dirt that cause rust. Use special lubricants to protect connectors from water and make them last longer.

Regular Checks and Cleaning Advice

Checking your vehicle connectors often keeps them working well. Clean connectors with a soft cloth and mild soap to remove dirt. For rusty connectors, scrub them with a wire brush. After cleaning, add a coating to stop future rust.

Look at wires often to keep electricity flowing well. Use a small brush to clean connectors you can see. Add dielectric grease to keep them working better. Be careful with wires when testing voltage to avoid breaking them. These steps help your connectors stay safe and reliable.

Reminder: Check your connectors every few months to find problems early.

Learning to install vehicle connectors keeps cars safe and working well. Using the right tools and steps avoids many problems.

Attach male pins tightly to the wires.

Add seals to keep out water and dirt.

Connect terminals to connectors for a snug fit.

Check your connectors often to keep them working properly. Regular checks help find and fix problems early. This care prevents breakdowns and improves how systems work.

Follow these steps to make your car projects better. Strong connections mean better performance and lasting success.

FAQ

Why use HSD connectors in car systems?

HSD connectors send data quickly in car electronics. They work well for cameras, entertainment systems, and digital networks. This makes systems faster and more reliable.

How can you keep vehicle connectors working longer?

Wipe connectors often with a soft cloth to clean them. Use dielectric grease to stop rust. Check wires and terminals for damage to keep electricity flowing.

Are vehicle connectors good for electric car charging?

Yes, some connectors, like HSD connectors, work for electric car charging. They move data fast and make strong connections for advanced car systems.

Tip: Always pick connectors that fit the job for best results.

See Also

Understanding HSD Connectors Essential for Automotive Applications

Enhancing Data Transfer in Vehicles with Advanced Connectors

Exploring High-Speed FAKRA-Mini Connectors for Automotive Innovation

Benefits of HFM Connectors for Modern Automotive Solutions

Transforming Vehicle Connectivity with HFM Connector Benefits