What Are Auto Electrical Connectors Plugs Used For in Cars

Vehicle connectors are very important for electrical systems in cars. These small parts help send signals and power smoothly. This is needed for modern cars to work well. They affect how your car runs and stays safe. As cars get smarter and more electric, these vehicle connectors are now a must-have for everything to work properly.

Key Takeaways

Auto electrical connectors are essential for the smooth operation of a car's electrical systems, affecting performance and safety.

Different types of connectors, such as crimp, Weather Pack, and HSD connectors, serve specific functions and environments, ensuring reliable connections.

Proper installation of connectors is crucial; using the right tools and techniques can prevent electrical issues and enhance longevity.

Regular inspection and maintenance of connectors can identify potential problems early, saving time and money on repairs.

Cleaning connectors and applying protective grease can prevent rust and water damage, ensuring optimal performance in harsh conditions.

Understanding the role of connectors in critical systems like engine control and safety features is vital for maintaining vehicle safety.

Advanced connectors like HSD are increasingly important in modern vehicles, supporting high-speed data transfer for advanced technologies.

Types of Auto Electrical Connectors

When fixing car electrical systems, you’ll see different connectors. Each type has a job and ensures wires stay connected. Knowing about them helps you pick the right one for your car.

Crimp Connectors

Crimp connectors are very common in car wiring. To use them, you put a wire’s end into the connector. Then, you squeeze it tight with a crimping tool. This makes a strong connection for both holding and electricity.

People like crimp connectors because they’re easy to use. You don’t need heat or solder to attach them. They stay strong even with shaking or movement. This makes them great for tough car jobs. Many car experts trust them for their strength and ease.

Weather Pack Connectors

Weather Pack connectors work well in tough conditions. They have a plastic cover that handles heat, chemicals, and water. These are great for places like under the hood or outside the car.

You’ll see Weather Pack connectors in important car systems like engines. They can hold one to six wires, so they’re flexible. Their strong design keeps them working even in bad weather or rough spots.

Blade Connectors

Blade connectors, also called spade connectors, are flat and simple. They slide into matching slots to make a secure connection.

These connectors are easy to use and good for quick fixes. They’re often used in car systems where wires need to be unplugged often. Their plastic cover makes them last longer and work well in many car tasks. Blade connectors are handy for fast repairs or changes.

Pin and Socket Connectors

Pin and socket connectors are very dependable for car wiring. They have two parts: a pin (male) and a socket (female). When joined, they make a strong link for sending electricity. Their design keeps them tight, even with shaking or movement.

These connectors are used in important car systems like engine controls. They work well where accuracy and strength are needed. They can handle high electricity, so experts often choose them. Pin and socket connectors come in different sizes to fit various wires.

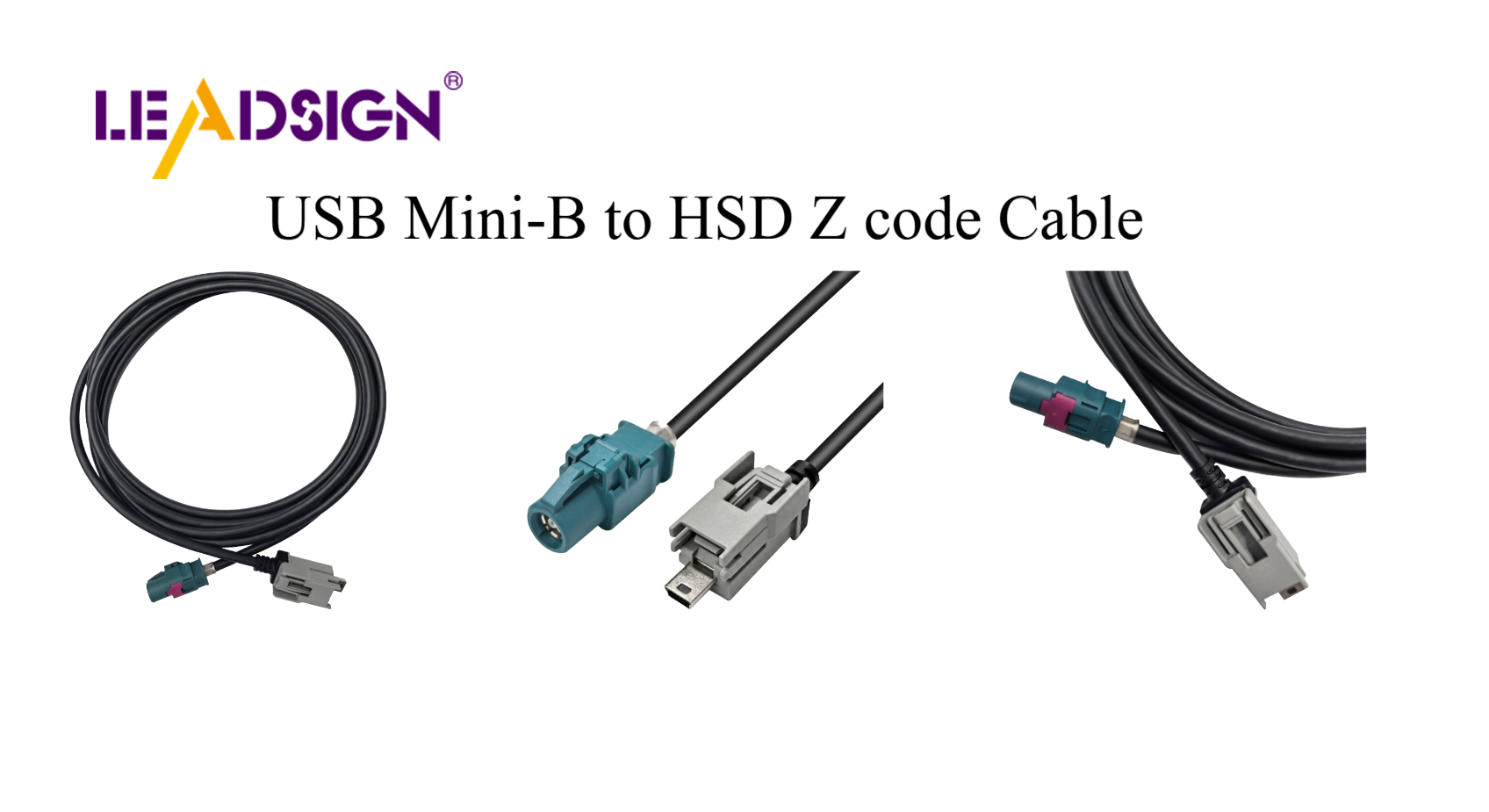

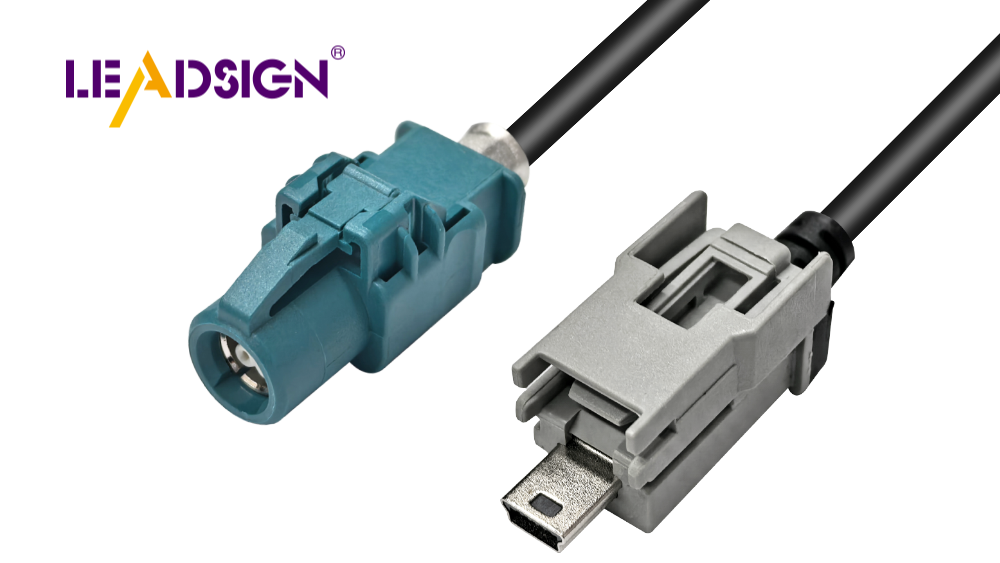

High-Speed Data (HSD) Connectors

High-Speed Data (HSD) connectors are key for modern cars. They are made to send data quickly, perfect for cameras and screens. They support USB, Ethernet, and other technologies for smooth communication.

HSD connectors are tough and have strong locks to stay secure. They hold cables tightly and prevent wrong connections. You’ll find them in car screens, networks, and wireless systems. If your car has advanced tech, HSD connectors help it work well.

Key Uses in Car Systems

Engine Control Systems

Your car's engine control needs connectors to work well. These systems handle fuel, ignition, and emissions. 2-pin connectors link sensors and parts to the engine control unit (ECU). This helps the ECU read data and keep the engine running smoothly. Without good connectors, engines can't work as precisely as they should.

For tough jobs, connectors must handle heat and shaking. Strong connectors keep the engine system working, even in hard conditions.

Lighting and Signal Systems

Car lights and signals need strong connectors to work right. These include headlights, brake lights, and turn signals. Connectors send power to these parts, helping you drive safely in bad weather or at night.

2-pin connectors are often used because they are simple and strong. They keep power steady for important lights like brakes and hazards. For heavy-duty cars, connectors must block water, dirt, and damage. Their tough build keeps lights working in rough places.

Infotainment and Communication Systems

Modern cars have infotainment systems for a better driving experience. These include screens, music, maps, and Bluetooth. HSD connectors send data fast between these parts, making them work smoothly.

Infotainment systems use many connectors to link devices. HSD connectors help with USB and Ethernet, letting screens and cameras connect well. This is important for tools like parking sensors and backup cameras.

As cars get smarter, infotainment needs real-time data. Good connectors make sure these systems work fast, giving you accurate info and entertainment.

Safety Features

Modern car safety features need strong connectors to work well. These include airbags, ABS, and stability control. Connectors help these systems talk to each other quickly. For example, during a crash, connectors send signals to activate airbags fast. Without good connectors, these systems might not work properly.

2-pin connectors are often used in safety systems. They link sensors and control units for smooth communication. Their tough design handles shaking and harsh conditions. This makes them perfect for important safety tasks. Strong connectors help protect you and your passengers on the road.

Autonomous Vehicles

Self-driving cars are the future, and connectors are key. These cars use LiDAR, cameras, and radar to drive safely. Connectors join these parts to the main computer for data sharing. This helps the car avoid obstacles and follow traffic rules.

High-Speed Data (HSD) connectors are very important in self-driving cars. They connect cameras, sensors, and screens with fast data transfer. Their locks keep cables secure, even on bumpy roads. They also stop wrong connections, which is vital for accuracy.

As self-driving cars improve, they need more advanced tech. Electric cars with self-driving features need connectors for power and data. These connectors are strong, light, and easy to use. By linking parts smoothly, connectors help self-driving cars become safer and better.

Installation and Maintenance Tips

How to Install Connectors Correctly

Installing connectors the right way helps your car work well. First, pick the correct connector for the job. Match the wire size and type to the connector. Use a good crimping tool to secure the wires tightly. Don’t use pliers or other random tools, as they can weaken the connection.

When stripping wires, be careful not to damage them. Push the wire fully into the connector before crimping it. Make sure the connection is tight and secure. If the connector has a lock, check that it clicks in place. This stops wires from coming loose while driving.

Good installation lowers the chance of electrical problems. It also makes connectors last longer, keeping your car running smoothly.

Checking Connectors for Damage

Check your connectors often to find problems early. Look for frayed wires, loose connections, or broken parts. Pay extra attention to areas near heat, water, or shaking, as these wear out faster.

Watch for discoloration or melting around connectors. These could mean overheating or short circuits. Test the locks to see if they still work well. Loose locks can cause bad connections and poor system performance.

Regular checks keep your car’s electrical parts working well. They also save money by fixing small issues before they get worse.

Cleaning and Protecting Connectors

Corrosion can harm your car’s electrical connectors. To clean them, use a soft brush and contact cleaner. Don’t use water or rough tools, as they can cause more damage. Gently scrub until the corrosion is gone.

After cleaning, add dielectric grease to protect against dirt and moisture. This grease keeps connectors safe from rust. For tough conditions, use covers or seals to protect connectors from damage.

Clean and protected connectors keep electricity flowing properly. This also helps your car’s electrical systems last longer and work better.

Using the Right Tools for Repairs

Using proper tools keeps your car’s connectors working well. The right tools make fixing easier and stop damage to wires.

Crimping Tools

Crimping tools secure wires tightly in connectors. They apply the right pressure for a strong hold. Don’t use pliers or random tools, as they can cause loose wires. A good crimping tool ensures the connection lasts.Wire Strippers

Wire strippers remove the plastic cover from wires safely. They keep the metal inside undamaged for better electricity flow. Pick one that fits your wire size for clean results.Multimeters

Multimeters check electrical problems in your car. They measure power, helping find bad connectors or circuits. This tool shows if a connector is working properly.Contact Cleaners

Contact cleaners clean dirt and rust from connectors. Clean connectors improve electricity flow and stop short circuits. Use cleaners made for electrical parts to avoid harm.Heat Guns

Heat guns shrink tubing around connectors for extra protection. They guard against water and shaking. Use the right heat setting to avoid melting wires.Connector Removal Tools

These tools help take out connectors without breaking them. They are great for tight spots or fragile connectors. Using the right tool avoids damage during repairs.

The growing use of advanced car tech shows why tools matter. Good tools save time and money while keeping your car safe. Always use tools made for cars to get the best results.

Common Problems and Fixes

Loose or Broken Connectors

Loose or broken connectors can mess up car systems. If connectors don’t hold tight, power and signals won’t pass well. This can cause blinking lights, faulty sensors, or system failures. Broken connectors, like cracked covers or bent pins, may cause random problems.

To fix this, check connectors often. Look for bent pins or loose locks. Replace broken connectors right away. For loose ones, make sure wires are crimped tightly. Also, check that locks click into place. Using strong, good-quality connectors can stop these issues from happening again.

Rust and Water Damage

Rust and water can harm car connectors badly. Water, salt, and humidity can make metal parts rust. Rust blocks electricity, causing poor performance or failures. Water inside connectors can lead to short circuits or more damage.

To fix this, clean connectors with special contact cleaner. Don’t use water or rough tools, as they can make it worse. After cleaning, add grease to protect against rust and water. In wet areas, use waterproof connectors or seals to keep them safe.

Overheating or Short Circuits

Overheating and short circuits are big problems for car systems. Overheating happens when connectors carry too much power or are poorly installed. This can melt plastic or damage metal parts. Short circuits occur when wires touch each other or metal, causing sparks or failures.

To fix overheating, use connectors that can handle the power load. Use proper tools to make tight connections and reduce resistance. For short circuits, check wires for damage or exposed parts. Cover these with heat-shrink tubing or replace them. Regular checks and good installation can stop these problems.

By knowing these common problems and fixes, you can keep your car working well. Strong connectors improve performance and keep your car safe and efficient.

Fixing and Changing Bad Connectors

Bad connectors can mess up your car’s systems. This might cause problems or even make driving unsafe. Finding and fixing these connectors keeps your car running well. Follow these steps to fix and change bad connectors.

1. Find the Problem

First, notice any signs of a bad connector. Check for flickering lights, broken sensors, or power cutting out. Look closely at connectors for damage like:

Cracked or broken housing: This lets dirt or water inside.

Bent or corroded pins: These stop electricity from flowing properly.

Loose connections: Wires that don’t stay tight can cause problems.

Use a multimeter to check if electricity flows right. If the reading is off, the connector or wire might be bad.

Tip: Check connectors near engines or moving parts. These areas wear out faster.

2. Take Out the Bad Connector

After finding the bad connector, remove it carefully. Use a special tool to avoid breaking wires or parts. If it has a lock, unlock it before pulling.

For crimp connectors: Cut the wire close to the connector to remove it cleanly.

For pin and socket connectors: Use the right tool to gently take out the pins.

Warning: Don’t pull too hard. This can break wires or other parts.

3. Pick the Right Replacement

Choose a new connector that matches the old one. Think about:

Material strength: Plastic should handle heat and chemicals.

Electric power: Make sure it works with the needed voltage.

Weather protection: Use weatherproof ones for outdoor or engine areas.

Good connectors last longer and work better. New ones like HSD connectors are strong and send data fast, perfect for modern cars.

4. Put in the New Connector

Strip the wire ends carefully. Place the wires into the new connector and secure them. Use a crimping tool for crimp connectors. For pin and socket connectors, line up the pins before locking them.

Check if the connection is tight.

Test the system to see if it works.

Tip: Add grease to the connector before installing. This stops rust and keeps it working longer.

5. Stop Future Problems

To keep connectors working well:

Check them often for damage.

Clean them with contact cleaner to remove dirt.

Use covers or seals in rough areas.

Fixing bad connectors quickly keeps your car safe and working well. Good connectors help systems run smoothly, especially in cars with advanced tech.

Car connectors are important for making systems work smoothly. They help with engine control, entertainment, and safety features in cars. Special connectors like HSD ones send data quickly for new tech like self-driving cars. Installing them correctly and checking them often keeps them working well. Fixing broken connectors right away stops problems and keeps you safe. As cars get more advanced, strong connectors are needed to handle the changes.

FAQ

What are auto electrical connectors?

Auto electrical connectors are small parts that link wires in cars. They send power and signals between systems to keep things working. These connectors are important for engines, lights, entertainment, and safety.

Why are reliable connectors important for my car?

Good connectors help your car's systems work well. They stay strong even in heat, shaking, or wet conditions. Strong connectors make systems like airbags and engines safer and better.

How do I identify the right connector for my car?

To choose the right connector, check the wire type and size. Look at the connector style, like crimp or blade types. Use tools like multimeters to test if it fits. Online guides can also help you pick and replace connectors.

Can I replace a damaged connector myself?

Yes, you can fix a bad connector if you have the tools. Use a crimping tool, wire stripper, and removal tool to do it. Follow step-by-step instructions to install it right. If unsure, ask a professional for help.

How do I protect connectors from rust and water damage?

Clean connectors often with contact cleaner to stop rust. Add grease to block dirt and water. Use waterproof covers for areas that get wet. These steps keep connectors safe and working.

What tools do I need for connector repairs?

You need these tools for fixing connectors:

Crimping tools to hold wires tightly.

Wire strippers to remove wire covers.

Multimeters to check electricity flow.

Contact cleaners to clean dirt and rust.

Heat guns to seal connectors safely.

Using the right tools makes repairs easier and safer.

How often should I inspect my car's connectors?

Check your car's connectors every few months or during service. Focus on spots near the engine or exposed to weather. Regular checks help find loose wires, rust, or heat damage early.

What should I do if a connector overheats?

If a connector gets too hot, turn off the car and check it. Look for melted plastic or burnt wires. Replace it with one that handles more power. Install it properly to avoid future problems.

Are advanced connectors like HSD connectors necessary for modern cars?

Yes, advanced connectors like HSD connectors are needed for new cars. They send data fast for cameras, screens, and self-driving tech. Their strong locks and durability make them perfect for modern systems.

Can bad connectors affect my car's safety?

Yes, bad connectors can make your car unsafe. Broken connectors can stop airbags or brakes from working. Regular checks and quick fixes keep these systems safe for you and your passengers.

See Also

Understanding HSD Connectors Essential for Automotive Applications

Why Fakra Connectors Are Crucial for Today's Vehicles

Significance of FAKRA Connectors in Vehicle Technology