Vehicle Cable Installation: A Custom Wire Maker's Guide

Correct vehicle cable setup is very important. It keeps cars safe and working well. When wiring a race car or custom project, the wiring harness is key. It keeps cables neat and safe. This stops short circuits and fires. In tight car spaces, cables face heat, wetness, and chemicals. A good wiring harness makes things work better. It also keeps your car project safe. Careful cable management protects your car's use and life span.

Key Takeaways

A well-organized wiring harness is crucial for vehicle safety and performance, preventing short circuits and potential fires.

Invest in essential tools like wire strippers, crimpers, and a multimeter to ensure safe and effective wiring.

Choose the right car cables based on voltage, current needs, and environmental factors to enhance durability and functionality.

Prioritize safety by unplugging the battery and wearing protective gear before starting any wiring project.

Plan the cable route carefully to avoid heat sources and sharp edges, ensuring a long-lasting installation.

Regularly test your wiring with a multimeter to identify and fix issues before they escalate, maintaining your vehicle's reliability.

Proper cable management not only improves safety but also enhances the overall appearance and efficiency of your vehicle's electrical system.

Tools and Materials Needed

When starting a car project, having the right tools is important. This makes sure your wiring is safe and works well. Let's look at the tools and materials you need.

Important Tools for Car Wiring

Wire Strippers and Crimpers

Wire strippers and crimpers are must-haves for car wiring. Wire strippers take off the plastic cover from wires. This helps make clean connections. Crimpers attach connectors to wires tightly. Good tools help your wiring last longer and work better.

Multimeter

A multimeter is a handy tool. It measures voltage, current, and resistance in car wiring. It helps find electrical problems and checks if your wiring works right. Using a multimeter makes sure your car wires are safe and meet standards.

Heat Gun

A heat gun is needed for heat shrink tubing. This tubing protects your wire connections. You use the heat gun to shrink the tubing around connectors. This keeps moisture and dirt away from your wiring.

Needed Materials for Car Wire Harnesses

Car Cables

Car cables are the main part of your wiring. Choose cables based on your project's needs, like voltage and conditions. Good car wires make sure everything works well and lasts long.

Connectors and Terminals

Connectors and terminals join wires together. They come in different types and sizes. Picking the right ones is important for your wiring to work well.

Heat Shrink Tubing

Heat shrink tubing insulates and protects wire connections. Put it over connectors and shrink it with a heat gun. This keeps your wiring safe from moisture and other things.

With these tools and materials, you can do your car wiring confidently. A good workspace and the right tools are key to success.

Picking the Right Car Cables

Choosing the right car cable is very important. You need to know what your project needs. This keeps your car safe and working well.

Knowing Car Specs

Voltage and Current Needs

You must know how much voltage and current your car cable needs. Each car system has its own needs. Using the wrong cable can cause problems. Check what your project needs. Make sure cables can handle the power. This keeps your wiring safe and working well.

Environment Factors

Think about where the car cable will be used. Car cables face heat, wetness, and chemicals. Pick cables that can handle these things. This stops damage and makes cables last longer. Look for cables with good insulation. This helps them work well in tough places.

Matching Cables to Project Needs

Cable Types and Sizes

Pick the right type and size of car cable. Different cables do different jobs. Some are for power, others for data. Size affects how much power it can carry. Choose a cable that fits your project. This makes sure your car system works right.

Insulation and Strength

Insulation keeps the car cable safe from outside things. It also stops short circuits. Pick cables with good insulation. This makes them strong and safe. Strong cables last longer and need less fixing. They keep your wiring working well.

By knowing these things, you can pick the right car cable. This makes sure your car wiring meets car industry needs.

Getting Ready for Wiring Harness Setup

Before you start putting in a wiring harness, get ready. This makes sure everything is safe and works well. Let's see what steps you need to take.

Safety First in Car Wiring

Safety is most important when working with car wires. Being careful stops accidents and helps things go smoothly.

Unplugging the Battery

First, unplug the battery to stop electric shocks. This makes sure no electricity is in the wires while you work. Use a special tester to check there's no power. This step keeps you safe and protects your car's wires.

Wearing Safety Gear

Always wear safety gear when working with wires. Gloves keep your hands safe from sharp wires. Goggles protect your eyes from sparks. Using safety gear lowers the chance of getting hurt.

Setting Up Your Workspace

A tidy workspace helps your wiring project go well. It makes work easier and stops mistakes.

Arranging Tools and Stuff

Put all your tools and materials in order before you start. Keep wire cutters, crimpers, and connectors close by. Being organized stops you from losing things and saves time. It also keeps your workspace safe.

Having Enough Light

Good light is needed for wiring work. Make sure your space is bright to see well and avoid errors. Good light helps you see wire colors and connections clearly. It also helps you focus better.

By doing these steps, you make wiring harness setup safe and easy. Safety and a neat workspace help you do your best in car wiring projects.

Step-by-Step Guide to Installing Custom Car Wire Harnesses

Making a good wire harness for your car needs some steps. This guide helps you put in custom car wire harnesses the right way.

Placing the Cables

Putting cables in the right place is very important. It makes sure your wire harness works well and safely.

Planning the Route

First, plan where your car cable will go. Find the best path that stays away from sharp things and moving parts. This is important for making safe and good wire harnesses. Use a wiring map to see the path. This helps you see the layout and stops problems when installing.

Staying Away from Heat

When placing cables, keep them away from hot places like the engine or exhaust. Heat can hurt the wire cover and cause problems. Make sure your wire harness is far from these hot spots to keep it strong and lasting.

Holding the Cables

After placing the cables, hold them tight. This stops them from moving and getting damaged later.

Using Ties and Clamps

Use ties and clamps to hold your wire harness. These tools keep cables still and stop them from moving. Space them evenly along the harness. This keeps cables safe and looking neat.

Allowing Movement

While holding cables, make sure they can move a bit. This lets them move without breaking connections. A flexible harness fits the car's moves better, lowering break risks.

Joining the Cables

The last step in making your wire harness is joining the cables. Good joins make sure your custom car wire harnesses work right.

Crimping and Soldering

Use crimping and soldering to join cables. Crimping is quick and strong, while soldering is more lasting. Pick the one that fits your project best. Both are important in a universal wire harness setup.

Covering Connections

After joining cables, cover the joins to keep them safe from water and rust. Use heat shrink tubing or tape for this. Good covering is key for a strong and safe DIY wire harness.

By doing these steps, you can wire a race car or any custom car project well. This guide helps you make your own wire harness with confidence, making sure your car wiring is up to standards.

Testing and Fixing Car Wiring

Testing and fixing car wiring is very important. It helps find and fix problems before they get worse.

Checking If It Works

Using a Multimeter

A multimeter is a key tool for checking wires. It measures voltage, current, and resistance. Set it to the right type. For voltage, connect the probes to the wire ends. This checks if the wire gives the right power. If numbers are wrong, you might need new wires or fix bad spots.

Checking Flow

Flow tests check if electricity moves well. Set the multimeter to flow mode. Touch probes to both wire ends. A beep or low number means good flow. No beep or high number means a break or bad spot. This keeps wires working well.

Fixing Common Wire Problems

Finding Bad Spots

Bad spots cause many wire problems. Look for loose or rusty connectors. Use a test light to check each spot. If the light stays off, the spot is bad. Tighten or clean connectors to fix it. This stops many wire issues.

Fixing Short Circuits

Short circuits happen when electricity goes wrong. This can hurt your car. To find one, use a multimeter to check flow to the car's ground. If it flows, there's a short. Look for broken covers or bare wires. Fix or change the bad part. Keeping wires in good shape stops shorts and keeps your car safe.

By doing these steps, you can test and fix car wiring well. This makes sure wires work right and keeps your car safe.

You have learned the key steps for car cable setup. By using this guide, your car's wiring will be safe and work well. A good wiring harness makes your custom project better and last longer. Try doing it yourself and use these tips for your car work. Proper wiring stops electric problems and keeps your car running well. With the right tools and know-how, you can handle any wiring task in your car projects.

What are cable management products that help a vehicle reach its fullest potential?

Cable management tools help cars work their best. They keep wires safe and stop electrical problems. These tools make sure connections stay strong. Good cable management helps cars perform better by reducing power loss. It also makes the car look tidy by keeping wires neat.

What is the importance of automotive cable management?

Car cable management is key for safety and efficiency. It stops fire risks and bad connections. Good management keeps wires in place, cutting down power loss over time. By managing cables well, your car becomes more reliable.

How does proper labeling in custom cable assembly benefit the installation process?

Labeling cables right is important to avoid mix-ups. It makes sure each wire connects correctly. This leads to safer and faster installation. Clear labels help find and fix problems easily, saving time during repairs.

Why is a wiring harness important in custom vehicle projects?

A wiring harness is like a backbone for custom cars. It keeps all wires organized and working. A good harness stops short circuits and failures. This boosts car performance and protects the electrical system, making it last longer.

How can you ensure the longevity of a wiring harness?

To make a wiring harness last, use good materials and install it right. Check it often for damage. Keep it away from heat and wet areas. Doing these things keeps your car's electrical system strong and lasting.

What are the common issues faced with wiring harnesses, and how can they be resolved?

Wiring harnesses can have loose connections or damaged insulation. Check them often for wear. Tighten loose parts and replace bad wires quickly. Use covers like heat shrink tubing to protect them and keep them working well.

How does a wiring harness improve vehicle safety?

A wiring harness makes cars safer by organizing wires. It stops wires from touching hot or moving parts, reducing fire risks. A neat wiring system ensures all parts get the right power, making the car safer.

Can you customize a wiring harness for specific vehicle needs?

Yes, you can make a wiring harness fit your car's needs. Customizing lets you choose the right wires and connectors. This helps your car's electrical system work better and fit your car perfectly.

What tools are essential for installing a wiring harness?

To install a wiring harness, you need wire strippers, crimpers, and a multimeter. Wire strippers remove insulation, crimpers attach connectors, and a multimeter checks voltage. These tools help you install the harness correctly.

How can you test the functionality of a wiring harness?

To test a wiring harness, use a multimeter. Check voltage and if electricity flows well. Test each connection to see if it gives the right power. These tests show if the harness works right and help fix any problems.

See Also

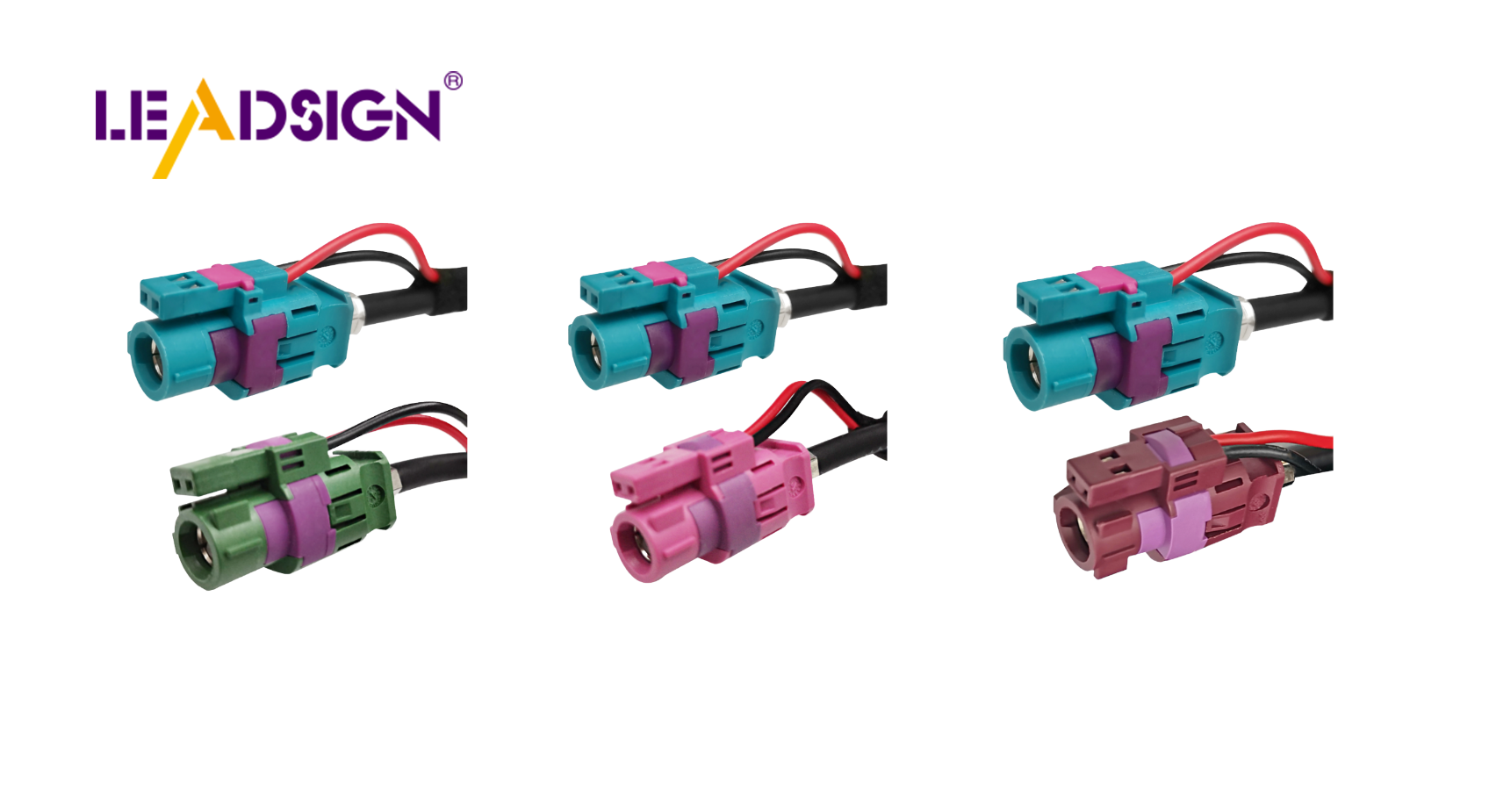

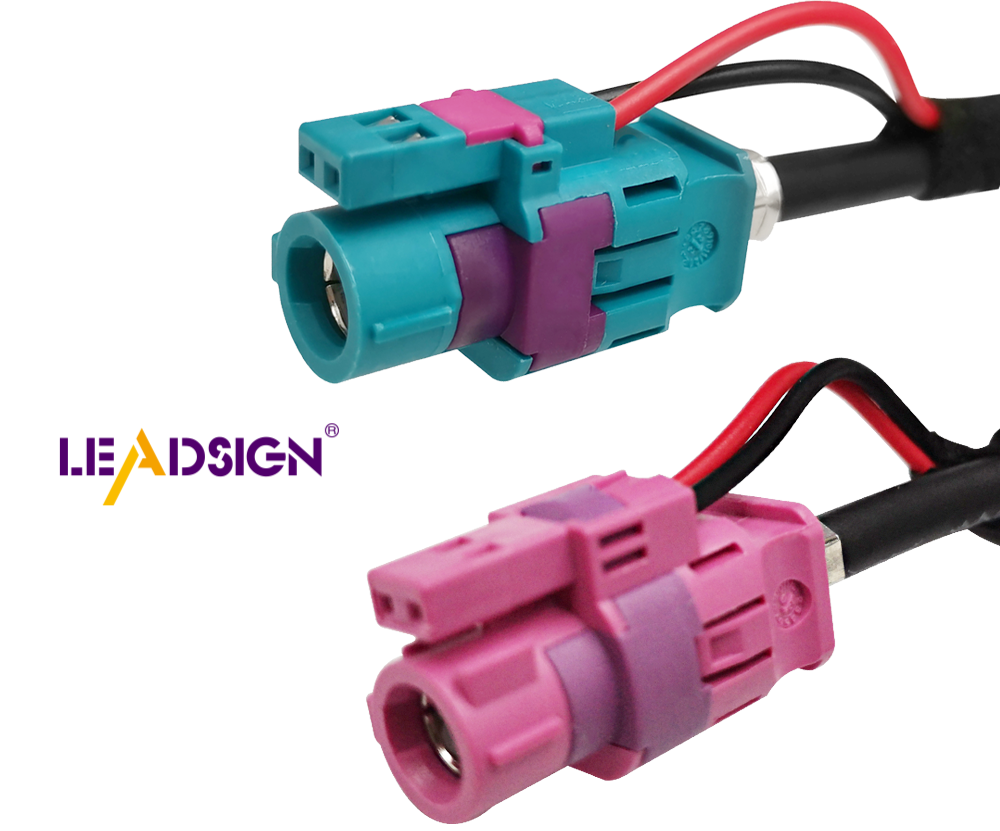

Understanding Fakra Cables: An In-Depth Overview

Harnessing the Potential of FAKRA Coaxial Connectors

Enhancing Automotive Data Flow: Superior Connectors and Cables

Exploring the Flexibility and Advantages of FAKRA Connectors