Guide to Vehicle Cable Assemblies for Custom Wire Makers

Vehicle cable assemblies are important for wire makers. They join many cables into one unit. This helps keep things neat and saves space. The design makes sure power, data, and signals move well. Using these assemblies makes your projects last longer. They can handle heat and wet conditions. These assemblies help vehicles work better and stay safe. They make sure electronic equipment works well. They are key to keeping vehicles strong and efficient.

Key Takeaways

Vehicle cable assemblies streamline multiple cables into one unit, enhancing organization and saving space in automotive applications.

Using high-quality cable assemblies improves performance by ensuring efficient power and data transmission, reducing signal loss.

Safety is paramount; cable assemblies secure connections, protecting against electrical risks and environmental factors like heat and moisture.

Customization is key—tailor cable assemblies to specific lengths and connector types to meet unique project requirements and enhance functionality.

Choosing the right suppliers is crucial; look for experienced manufacturers with good reviews and industry certifications to ensure quality.

Regular quality checks and compliance with industry standards are essential for maintaining safety and performance in cable assemblies.

Emerging technologies, such as electric and self-driving cars, require specialized cable assemblies to handle increased power and data demands.

Understanding Vehicle Cable Assemblies

What They Are and Why They Matter

A cable assembly is a bunch of wires in a cover. This cover keeps power and signals moving safely. They help electricity or signals travel between parts. In vehicles, they connect parts for power and signals. They are used in cars, planes, and hospitals.

Important Parts

To know cable assemblies, learn their main parts:

Cables

Cables are the main part. They carry power and data. They can be made of copper or fiber optic.

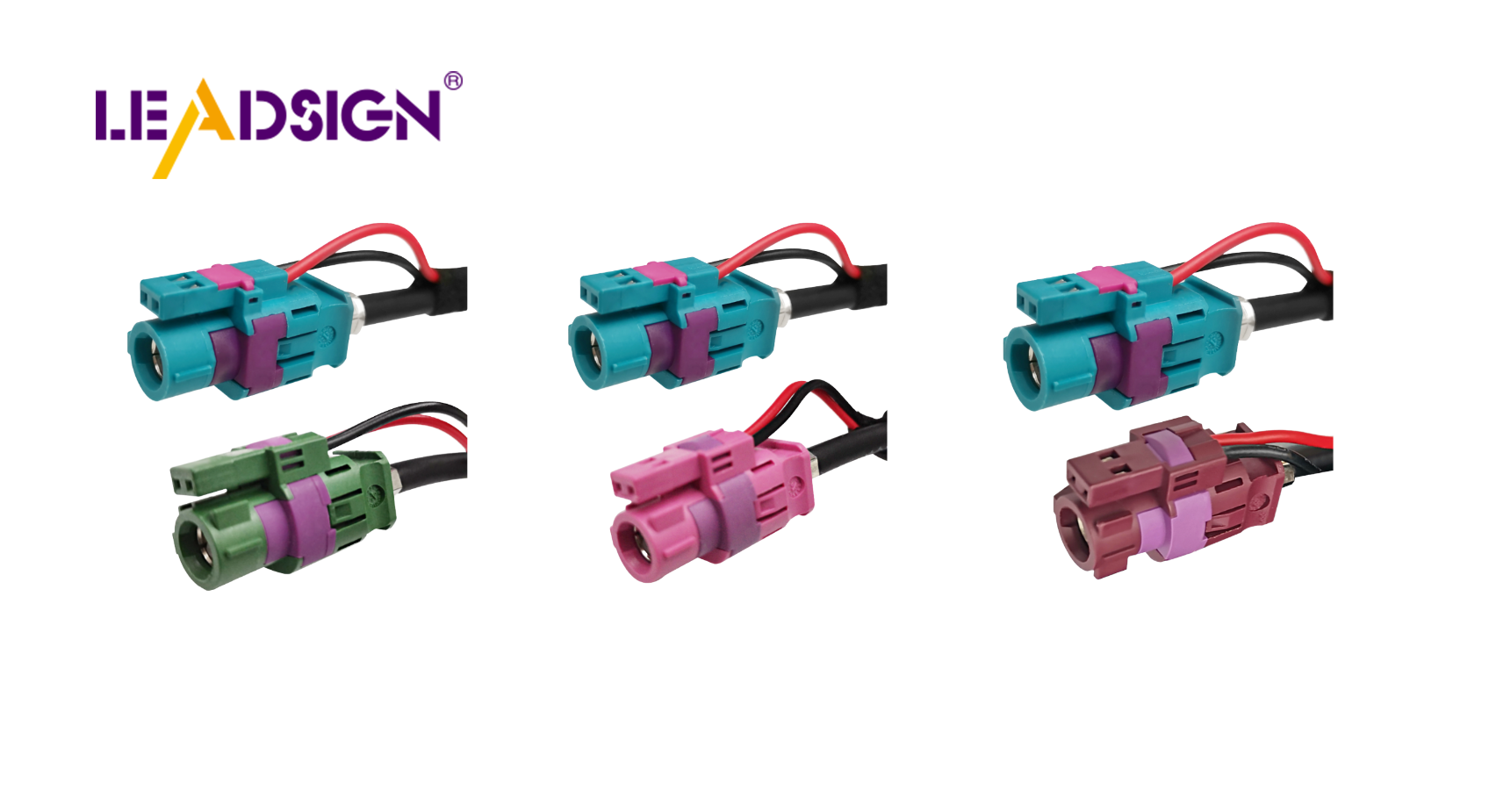

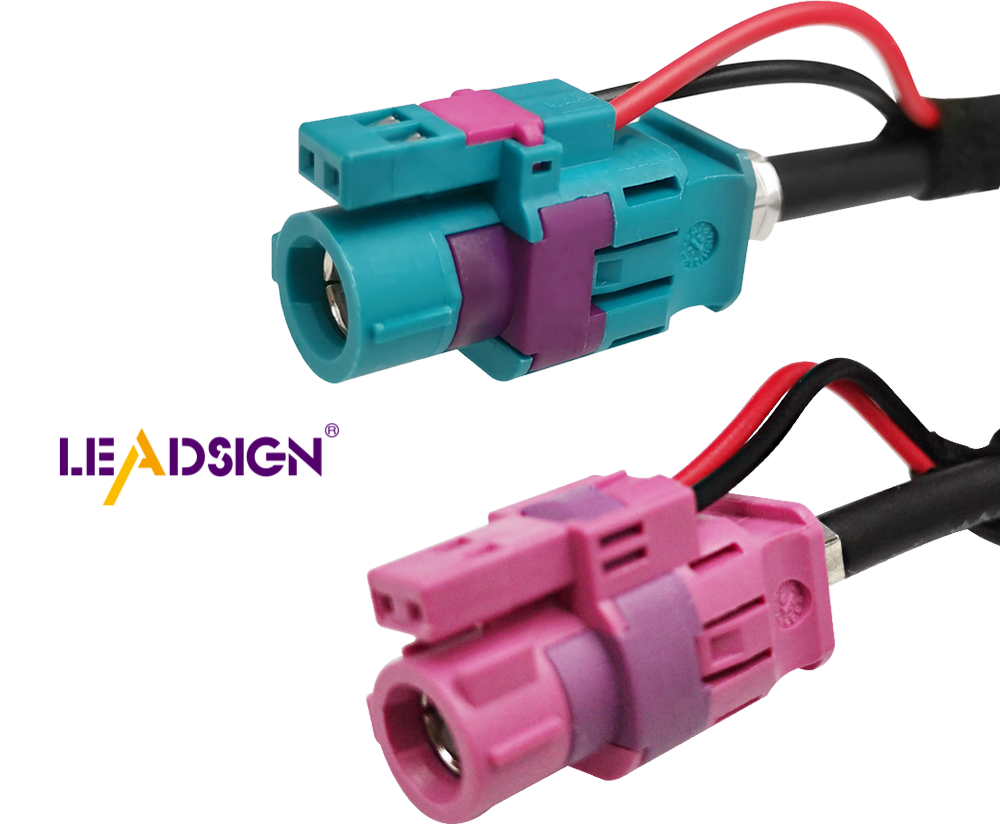

Connectors

Connectors link cables to devices. They keep connections strong. Good connectors stop signal loss.

Insulation Materials

Insulation keeps cables safe from heat and water. It stops electrical problems and keeps things working well.

Why Use Cable Assemblies

Cable assemblies have many good points:

Better Performance

They make power and data move well. This stops signal loss and helps systems work better.

More Safety

Safety is very important. Cable assemblies make things safer by keeping connections secure.

Easier Setup

Putting in many cables can be hard. Cable assemblies make it easy by putting cables together. This saves space and makes fixing things simpler.

How Cable Assemblies Help Cars Work

In cars, cable assemblies are very important. They help cars run well and safely. These cables link different parts inside a car. They are needed for modern car design.

Where They Are Used in Cars

Cable assemblies are used in many parts of cars:

Engine Parts

In engines, cable assemblies move power and data between parts. They keep the engine running well by linking sensors and controls. This helps the engine work smoothly and saves energy.

Entertainment Systems

Entertainment systems need cable assemblies for sound and video. They connect screens, speakers, and controls. This makes sure passengers have fun without messy wires. It also makes the car look nice inside.

Safety Systems

Safety systems in cars use strong cable assemblies. They link airbags, brakes, and stability controls. This helps keep the car safe and protects people inside.

New Ideas and Tech

As cars change, new ideas affect cable assemblies:

Electric Cars

Electric cars need special cable assemblies. They handle high power and data. These cables must be tough for batteries and chargers. Using new materials helps them work well in electric cars.

Self-Driving Cars

Self-driving cars use smart cable assemblies. They connect sensors and cameras. This helps the car make quick decisions and drive itself. As more self-driving cars come, we will need better cable assemblies.

Cable Assemblies vs. Wire Harnesses

Knowing the difference between cable assemblies and wire harnesses is important. Both connect electrical systems but have different uses.

What They Are

A cable assembly has many cables in a cover. This cover keeps power and signals safe. They are used in big projects to save time. They are good for high power, like in cars and computers.

A wire harness assembly is a group of wires. They send power or signals. They don't always have a cover. They use connectors to join parts. Wire harnesses became popular in cars in the 1920s. They help keep wires neat and easy to fix.

When to Use Them

Pick a cable assembly for strong power and data needs. They are good where protection from heat and water is needed.

Choose a wire harness assembly to organize wires in small spaces. They are great for saving space and easy setup. They are used in cars and machines.

Both are useful in cars. Knowing their differences helps you choose the best one for your project.

Designing and Customizing Cable Assemblies

When you start designing a cable assembly, think about many things. These help make sure your custom cable assemblies work well for your projects.

Things to Think About

Environmental Conditions

Think about where the cable assembly will be used. Will it be very hot, wet, or near chemicals? These can change what materials you use. For example, if it's in a hot engine, use heat-proof insulation. This keeps the assembly working and safe.

Electrical Needs

Know the electrical needs. Find out the voltage and current levels. This helps pick the right cables and connectors. Good choices stop overheating and make things work better. It also makes sure the assembly can handle the power without breaking.

Customization Choices

Customization lets you make the cable assembly fit your needs. This is important for the best performance.

Custom Lengths and Shapes

Custom cable assemblies can be made to the right length and shape. You can choose the exact length needed, cutting down extra cable. This makes setting up and fixing easier. It also makes your project look neat by removing extra loops.

Special Connectors

Picking special connectors is another choice. These connectors fit well and keep connections strong. They stop signal loss and keep connections good. By choosing the right connectors, you make your custom cable assembly work better.

Expert Testimony: Custom Cable Assembly Experts say it's smart to let experts handle custom cable assembly needs. They say, "Companies are letting experts do their custom cable assembly to get good quality and more output."

Designing a wire harness assembly needs careful thought about these things and customization choices. By focusing on these, you make a custom wire harness that fits your needs and works well.

Buying Choices and Things to Think About

When buying cable assemblies, knowing your choices is key. This part helps you find good suppliers, check quality, and manage costs.

Finding Good Suppliers

Finding good suppliers is important for your projects. Look for suppliers with a good history in cars. They know what cars need.

Research and Reviews: Search online for suppliers. Read reviews from other buyers. This helps you know if they are good.

Certifications: See if the supplier has certifications. This shows they follow rules and do good work.

Experience: Check how long the supplier has made cable assemblies. Experienced ones give better products.

OEM Procurement Manager: "Picking suppliers who cut costs but keep quality is smart."

Checking Quality and Rules

Quality and rules are very important for cable assemblies. Make sure products meet standards.

Quality Checks: Do regular checks to see if assemblies are good. Test for strength, work, and safety.

Compliance with Standards: Ensure assemblies follow industry rules. This is crucial for car safety and work.

Supplier Audits: Check suppliers to ensure they make things well. This finds problems early.

Cost and Budgeting

Managing costs is key for success. Balance quality and price.

Bulk Purchasing: Buy many assemblies at once. This can save money and make work easier.

Budget Planning: Make a budget for all costs like materials and shipping.

Negotiation: Talk to suppliers for better prices. Good relationships can help get better deals.

By focusing on these buying choices and thoughts, your projects can be successful and save money. Picking the right makers is key for the best results.

Picking the right cable assembly is very important. It helps your car projects work well. These assemblies connect different parts. They make things safe and easy to set up. Good cable assemblies improve your car's systems. They help power, data, and signals move smoothly. This is very important today. Buying good cable assemblies makes things work better. It also makes your car systems last longer.

FAQ

What are Cable Assemblies?

Cable assemblies are groups of cables and connectors in one unit. They save space and give power that one cable can't. You can change them to fit needs like voltage and length. They can be made from copper or fiber optic.

What are Cable Assemblies Used For?

Cable assemblies do many jobs. They send electricity or signals between devices. They power electronics, help computers talk, and connect car parts. They are important in telecom, cars, planes, and hospitals.

How Can You Procure Cable Assemblies?

You can buy cable assemblies from many sellers. For special orders, talk to a skilled maker. Tell them what you need, and they will make the right assembly for you.

Why Choose Custom Cable Assemblies?

Custom cable assemblies fit your needs exactly. You pick the length and connectors for best performance. This helps your projects work better and last longer.

What Materials are Used in Cable Assemblies?

Cable assemblies use materials like copper and fiber optic. The choice depends on what you need, like fast data or protection from weather.

How Do Cable Assemblies Enhance Safety?

Cable assemblies keep connections safe and lower electrical risks. They protect from heat and water, stopping damage and danger.

What is the Difference Between Cable Assemblies and Wire Harnesses?

Cable assemblies and wire harnesses both link systems but are different. Cable assemblies have many cables in a cover for strong power. Wire harnesses are grouped wires without a cover, good for small spaces.

Can Cable Assemblies Be Used in Harsh Environments?

Yes, cable assemblies can work in tough places. With the right materials, they stay safe and work well in extreme conditions.

How Do Cable Assemblies Improve Automotive Performance?

In cars, cable assemblies help by moving power and signals well. They keep engines, entertainment, and safety systems working, making cars run better.

Are There Any Emerging Trends in Cable Assemblies?

New trends in cable assemblies include solutions for electric and self-driving cars. These cars need special assemblies for high power and data, ensuring smooth and safe operation.

See Also

Why HSD Cable Assemblies Are Crucial for Today’s Tech

Enhancing Automotive Data Flow with Superior Connectors and Cables

Harnessing High-Speed FAKRA-Mini Connectors for Automotive Innovation

Understanding the Role of Fakra Connectors in Automotive Systems

Benefits of High-Speed FAKRA-Mini Connectors for Automotive Applications