How to Use Automotive Wiring Connector Types Effectively

Selecting the appropriate auto wire connector types is crucial for maintaining the safety and reliability of your vehicle's electrical systems. These connectors facilitate communication between various components, such as the engine and radio, reducing the risk of failures. It's especially important in high-temperature environments, where a connector operating at 120°C is ten times more likely to fail than one at 20°C. Optimal connectors not only streamline car repairs but also expedite vehicle servicing, ultimately saving time.

Understanding Automotive Wiring Connector Types

When fixing car electrical systems, knowing wire connector types is key. These connectors help car parts talk and work right. Let's look at common and special connectors you might see.

Common Types of Connectors

Blade Connectors

Blade connectors are very popular in cars. They have a flat metal piece that fits into a slot. You use them to connect wires to switches or relays. They are quick to connect and disconnect, perfect for frequent changes.

Bullet Connectors

Bullet connectors look like bullets and join wires securely. They have male and female ends that snap together. Used in car lights, they stay connected even when the car moves.

Butt Connectors

Butt connectors join two wires end-to-end. They're great for extending or fixing broken wires. Insert stripped wire ends into each side and crimp them tight for a strong hold.

Ring and Spade Terminals

Ring and spade terminals attach wires to screws or studs. The ring forms a circle; the spade looks like a fork. Often used for grounding or battery connections, they stay secure.

Specialty Connectors

Weatherproof Connectors

Weatherproof connectors keep out water and dirt. Needed outside or where cars face weather, they have seals to stop leaks.

High-Temperature Connectors

High-temperature connectors handle heat well near engines or exhausts. Made from materials that don't melt easily, they keep connections safe in hot spots.

Knowing these connector types helps you pick the right ones for your car's electric parts, keeping everything safe and working well.

How to Use Car Wire Connectors

Knowing how to use car wire connectors helps your car work well. Follow these steps to get wires ready and connect them right.

Getting Ready

Collecting Tools You Need

Before you begin, gather tools. You need a wire cutter, crimper, and the right connectors. Having tools ready makes things easier and faster.

Staying Safe

Safety is very important with electric stuff. Always unplug the battery to stop shocks. Wear goggles for eye safety from flying bits. Make sure your area is dry and bright to avoid accidents.

Easy Steps Guide

Cutting Off Wire Cover

Start by cutting off the wire cover. Use a cutter to take off about half an inch of cover from the wire end. This shows the metal inside, which connects to the connector types. Be careful not to cut the wire itself.

Picking the Right Connector

Choose the right connector for your job. Think about where it will be used and how much power it needs. Use waterproof connectors outside and heat-proof ones near engines.

Squeezing on Connector

Put the bare wire in the connector. Use a crimper tool to hold it tight in place. Press hard so it's secure. A good squeeze stops wires from slipping out.

Checking Connection Works

After squeezing, check if it works. Plug back in the battery and turn on electric parts. See if everything works fine. If not, check again for loose or bad squeezes.

By doing these steps, you can use car connectors well for your car's electric parts. Good prep and work make safe connections that last.

Applications and Considerations

When using car wire connectors, think about some important things. This helps them work well and last long.

Picking the Right Connector for the Job

Choosing the right connector keeps your car's wires safe. Here are some things to think about:

Environmental Considerations

Where you use connectors matters a lot. If they get wet or dirty, they should be weatherproof. This stops rust and breaking. Studies show that weather changes can make connectors fail more often. So, always pick ones that can handle where they'll be used.

Electrical Load Needs

Each connector can carry only so much electricity. Make sure it can handle what your car needs. If not, it might get too hot and break. Good connectors help your car's electric parts work better by carrying enough power.

Common Mistakes to Avoid

Avoiding mistakes with connectors saves time and problems later.

Wrong Crimping

Crimping connects wires tightly to connectors. Doing it wrong makes loose connections, causing electric problems. Always use the right tool and way to crimp well. A study showed that good crimping stops wires from coming apart.

Using the Wrong Connector Type

Using a wrong connector can mess up everything. For example, if it's not weatherproof outside, it might rust and break. Always match the connector type with where you'll use it and how much power it needs.

By knowing these tips, you can use car wire connectors safely in your vehicle's electric systems. Choosing and putting them on right makes them last longer and work well.

FAQs and Troubleshooting

Common Questions

How to Know Connector Types

Finding connector types can be hard. Focus on main parts. Look at the shape and size. Blade connectors are flat metal pieces. Bullet connectors look like bullets with two ends. Butt connectors join wires straight. Ring and spade terminals go on screws or studs. Use these clues to tell them apart.

Tips for Taking Care of Connectors

Taking care of car connectors helps them last longer. Check them often for damage or wear. Clean with a soft brush to remove dirt. Use special grease to stop rusting. Make sure they stay tight by checking now and then. These tips keep your car's electric system working well.

Fixing Usual Problems

Loose Connections

Loose connections can cause trouble in your car's electric parts. To fix, first unplug the battery for safety. Then gently pull wires to check if loose. If loose, use a crimper tool to make it tight again. Plug back the battery and test if everything works right.

Rust Problems

Rust can hurt connectors and stop electricity flow. To fix, unplug the battery and look for rust spots on connectors. Clean rusty areas with a wire brush or sandpaper gently. Put special grease on to stop more rust later on. Plug back the battery and see if all works fine.

Using the right car wire connectors keeps your car safe. Good connectors help parts talk well, stopping problems. Cars today need better connectors because they are more complex.

To use them well, follow good steps. Pick connectors that fit the place and power needs. Install them right and check often to stop loose wires and rust.

By doing this, you make sure your car's wires work well for a long time, keeping it running smoothly.

See Also

Exploring the Benefits of HFM Connectors in Automotive Sector

Understanding the Fundamentals of HSD Connectors in Auto Sector

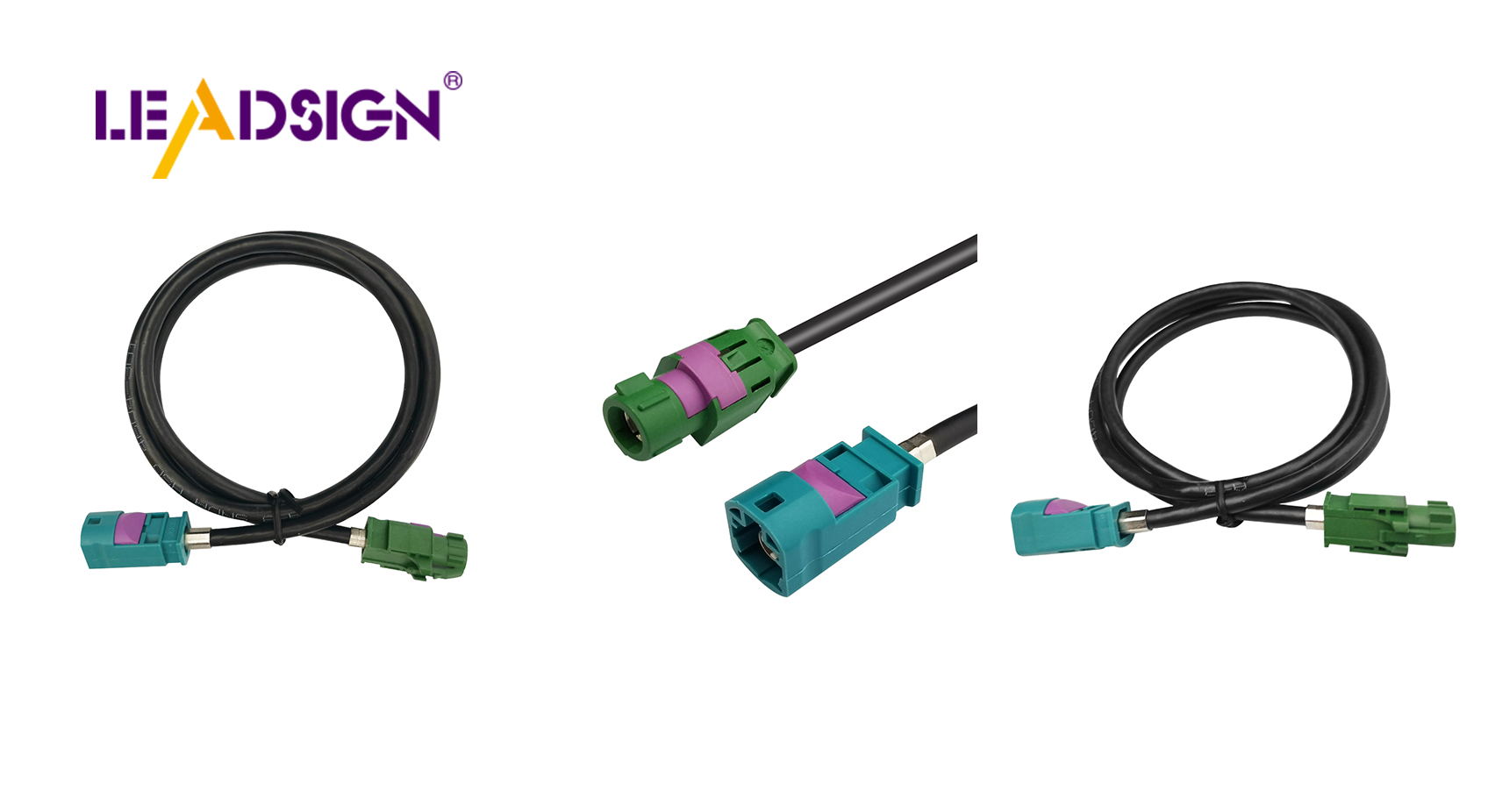

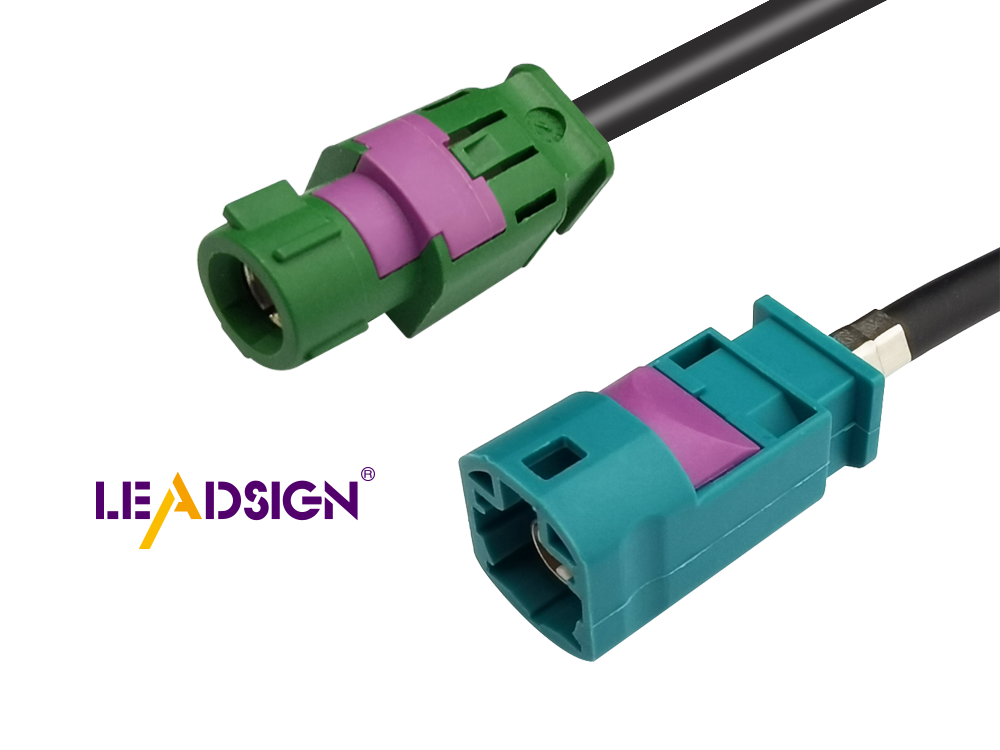

Significance of Fakra Auto Connectors in Contemporary Cars