How to Use Automotive Electrical Connectors Types Effectively

Automotive electrical connectors are crucial for your vehicle's systems, facilitating reliable connections between various electrical components. These connectors play a vital role in safety systems such as airbags and ABS brakes. Effective connections ensure that sensors and components communicate swiftly, maintaining passenger safety. Understanding the different automotive electrical connectors types is essential for keeping your vehicle operating efficiently and safely. By selecting the appropriate connectors, you ensure your car functions smoothly and securely under all conditions.

Understanding Car Electrical Connectors Types

In cars, knowing different connector types is important. These connectors help car parts talk to each other, keeping everything working well and safe.

Main Parts and Jobs

Each car electrical connector has key parts with special jobs:

Conductors

Conductors are the main part of a connector. They move electricity between parts. Choose conductors made from good materials like copper or aluminum for better power flow.

Insulators

Insulators cover conductors to stop unwanted contact with other car parts. They prevent short circuits and failures. Strong insulators make your car's electric system last longer.

Terminals

Terminals connect the conductor to outside circuits. They need to fit well to stay connected. Well-crimped terminals keep connections stable, which is important for your car's smooth running.

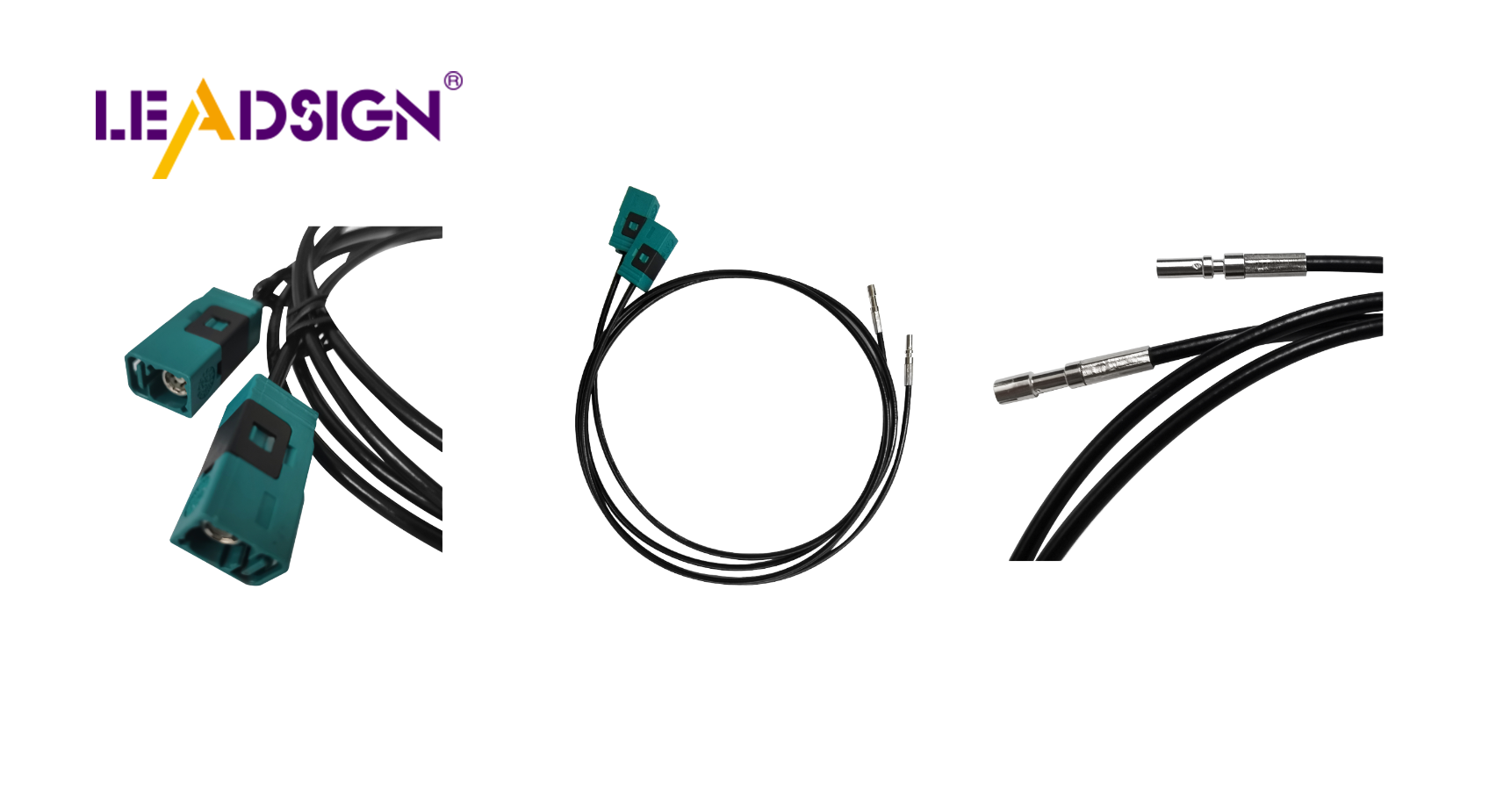

Common Car Electrical Connector Types

Cars use several common connectors, each for specific uses:

Blade Connectors

Blade connectors are in car lights and have a flat blade fitting into a slot. They're quick and easy, great for when you need frequent disconnections.

Pin Connectors

Pin connectors have round pins for connections. They're used in data and sensor areas where exact fit is needed. You see them in systems like infotainment and navigation.

Butt Connectors

Butt connectors join two wires end-to-end smoothly. They're used when splicing wires is needed. A good crimp on butt connectors keeps connections reliable.

Knowing these basic parts and common types helps you pick the right connectors for your car, making it safer and more efficient.

Choosing the right car connectors is very important. It helps your car work well and stay safe. You should think about a few things to pick the best ones.

First, check what your car needs for electricity. Different connectors handle different amounts of power. Pick ones that won't get too hot or break. This keeps your car's electric parts working safely.

Next, consider where you drive your car. Connectors must handle changes in weather, wetness, and shaking. If you drive in really hot places, choose connectors made for heat. This stops them from breaking down.

Also, make sure the connectors fit your car's systems. Not all connectors work with every car model. Check if they match your car to avoid problems.

Sometimes, special connectors are needed for certain jobs.

High-temperature connectors are good for hot places. They don't melt or get damaged by heat.

Waterproof connectors are great if your car gets wet often. They stop water from causing rust or electric problems.

Picking the right connectors means knowing what your car needs and where it goes. By thinking about electricity, weather, and fit, you keep your car running well. Special connectors like those for heat or water can make it even safer and better.

Best Ways to Use Connectors Well

To keep your car's electric system working, use connectors right. These tips help keep connections strong and stop problems.

How to Install

Crimping Right

Crimping is key when adding connectors. Use the right tools for crimping. A good crimp makes wires and ends stick well. Don't use pliers; they can break things. Buy a good crimp tool made for your connector type. This helps press right, making sure it's tight and works well.

Keeping Connections Tight

After crimping, check if it's tight. Pull the wire gently to see if it stays put. Loose wires can cause electric problems or fires. Make sure the connector fits in its spot fully. This stops it from coming loose and keeps things running fine.

Checking and Fixing

Look Often

Check your car's connectors often. See if they're worn out, rusty, or broken. These can mess up connections and how your car works. By checking often, you find problems early and fix them before they get worse.

Spotting Problems and Fixing Them

Common connector problems are rust, loose wires, or broken ones. If rusty, clean with cleaner and add a coat to stop more rust later. Tighten loose wires and change bad ones fast. Doing this keeps your car's electric system lasting long.

"Connector reliability means they work under set conditions for some time." By following these tips, you make sure your car's connectors last long and work well.

By using these tips, you keep your car's connectors working great. This not only makes your car's electric parts last longer but also makes them work better overall.

To use automotive electrical connectors well, keep these tips in mind:

Know the Types: Learn about different connectors and what they do. This helps you pick the right one for your car.

Use Good Methods: Install them correctly by crimping and checking often. This keeps your car's electric parts working longer.

Learn More: Ask experts or read more to know better. Some say, "Deutsch and Weatherpak connectors are top picks," showing why good choices matter.

By following these steps, your car's electric system will work safely and well.

See Also

The Significance of FAKRA Connectors in Auto Industry

The Role of HSD Connectors in Auto Sector

The Benefits of HFM Connectors in Auto Sector

The Fundamentals of HSD Connectors in Auto Sector

The Significance of Fakra Auto Connectors in Contemporary Cars