How to Effectively Use Automotive Electrical Connectors Types in Your Projects

Good electrical connections are crucial in automotive projects. You may encounter issues such as loose wires or poor connections, which can disrupt the vehicle's electrical system. These problems can lead to inefficient operation and safety hazards. Different types of automotive electrical connectors play a vital role in addressing these issues. They ensure secure and reliable connections, enhancing the performance and safety of your automotive projects. Understanding the various automotive electrical connectors types can help prevent common wiring issues and improve the overall quality of your car projects.

Understanding Automotive Electrical Connectors Types

What are Automotive Electrical Connectors?

Automotive electrical connectors are key parts of a car's electrical system. They connect wires and cables to keep electricity flowing smoothly. These connectors help your car's electrical connections stay strong. Without them, your car might not work well often.

In car projects, these connectors are very important. They make sure connections stay tight even with shaking or bad weather. Using the right connectors makes your car's electrical system safer and more reliable. This keeps all electronic parts working well.

Types of Automotive Electrical Connectors

You will see different automotive electrical connectors types, each for special uses:

Blade connectors: These have flat, blade-like ends. You use them when you need to disconnect quickly. They give a good connection and are easy to put in.

Bullet connectors: Shaped like bullets, they fit into matching sockets. You use them where you unplug often. They fit tightly and are simple to handle.

Butt connectors: These join two wires end-to-end. You use them to extend or fix wiring. They hold strongly and are great for permanent setups.

Ring and spade connectors: These have ring or spade-shaped ends that attach to screws or bolts securely. They're used a lot for grounding jobs.

Choosing the Right Connector for Your Project

Picking the right connector means thinking about several things. You must check how much current and voltage your system needs. Make sure the connector can handle these numbers so it doesn't fail.

It's important that the connector fits your project needs too. Choose ones that match the wire size and type you're using. Think about what conditions your project will face, like moisture or heat changes.

Knowing these things helps you pick the best automotive electrical connectors types for reliable projects.

Tips for Using Connectors Well

Using the right ways with automotive electrical connectors types makes them work better. Let's look at some good tips.

Crimping or Soldering?

Pick crimping or soldering based on your project needs. Each has good and bad points.

Crimping: Good and Bad Points

Crimping squeezes a connector onto a wire. It's fast and doesn't need heat. With the right tools, it makes strong links. Use crimping when you need quick connections. But if done wrong, it can be weak. Always use the right tool for your specific automotive electrical connectors types.

Soldering: Good and Bad Points

Soldering melts solder to join wire and connector. It makes a strong bond that lasts under stress. It's great for long-term links but takes time and care to avoid damage. You need the right gear and skills to do it well.

Best Ways to Install Connectors

Installing automotive electrical connectors types correctly keeps your system working well.

Needed Tools

You need special tools like wire strippers, crimpers, and solder irons. These help you handle different automotive electrical connectors types easily.

Steps to Install

Get Wire Ready: Strip off some insulation with a stripper so enough wire shows.

Pick Connector: Choose the right type for your job based on wire size and use.

Attach Connector: For crimping, put the wire in and squeeze with a tool; for soldering, place wire, add solder, heat until it bonds.

Check Connection: Look for loose wires or weak spots; it should hold tight.

Test Connection: Use a multimeter to check if it's working properly.

Fix Common Connector Problems

Even using best practices, problems can happen with automotive electrical connectors types. Knowing how to fix them is key.

Bad connections cause flickering lights or parts not working right. Check for rust, loose wires, or broken coverings on connectors.

Bad connections cause flickering lights or parts not working right. Check for rust, loose wires, or broken coverings on connectors.

Fixes for Usual Issues

Rusty Parts? Clean them with contact cleaner then dry before reconnecting.

Loose Links? Re-crimp or re-solder so they're firm again.

Worn Parts? Swap out damaged ones with correct new ones to stop future trouble.

By knowing these tips and using them well, you make your car projects work better!

Choosing the right connectors is very important. It helps your car projects work well. Pick the correct connector types for strong connections. Use what you learned to make projects better. Good connectors can really help your project succeed. One happy customer said, "This is the best service ever!" This shows why good connectors and methods matter. Use these ideas to make your car projects great!

See Also

Enhancing Automotive Connectivity with HSD Connectors

Benefits of HFM Connectors for Automotive Applications

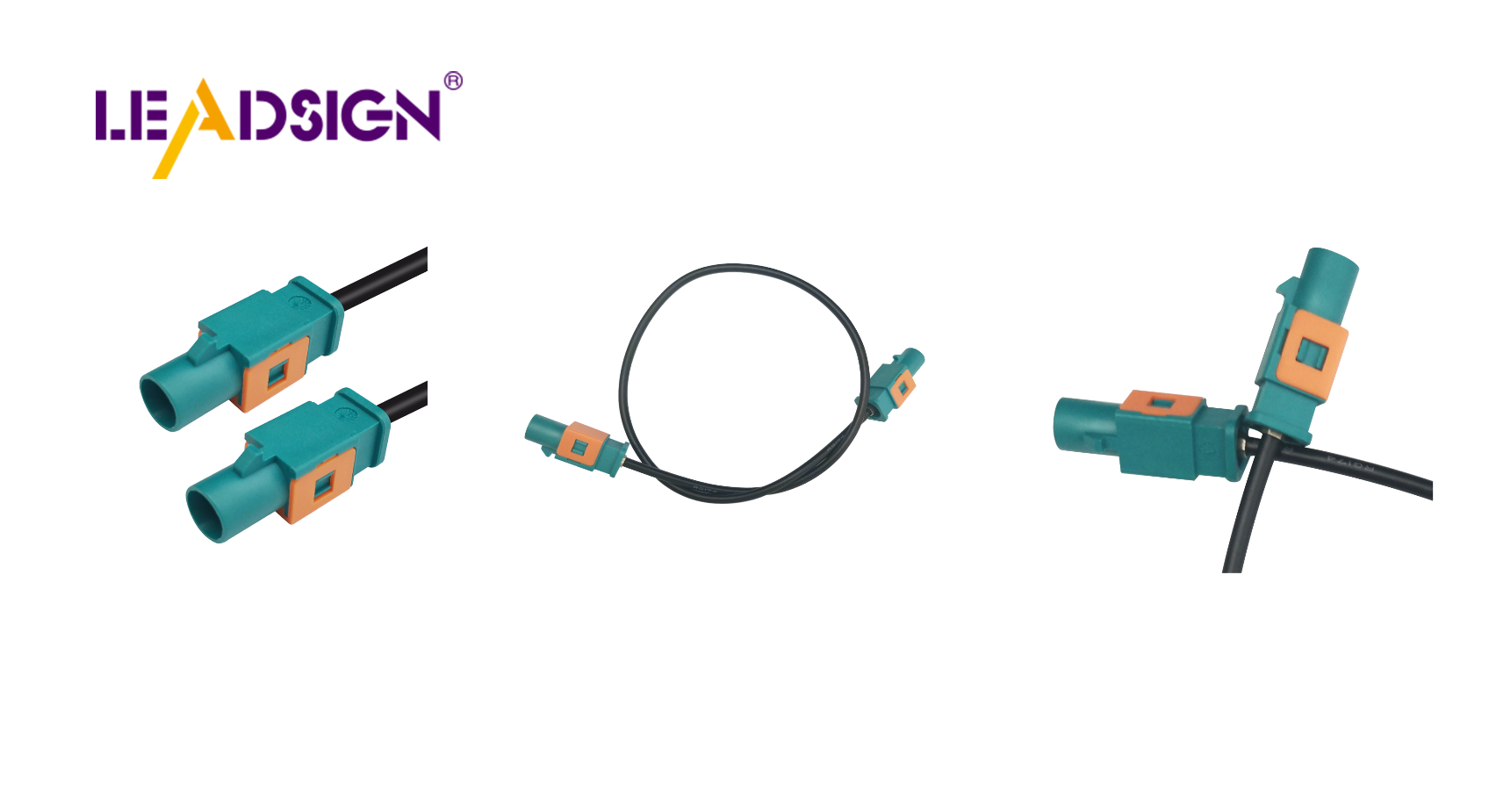

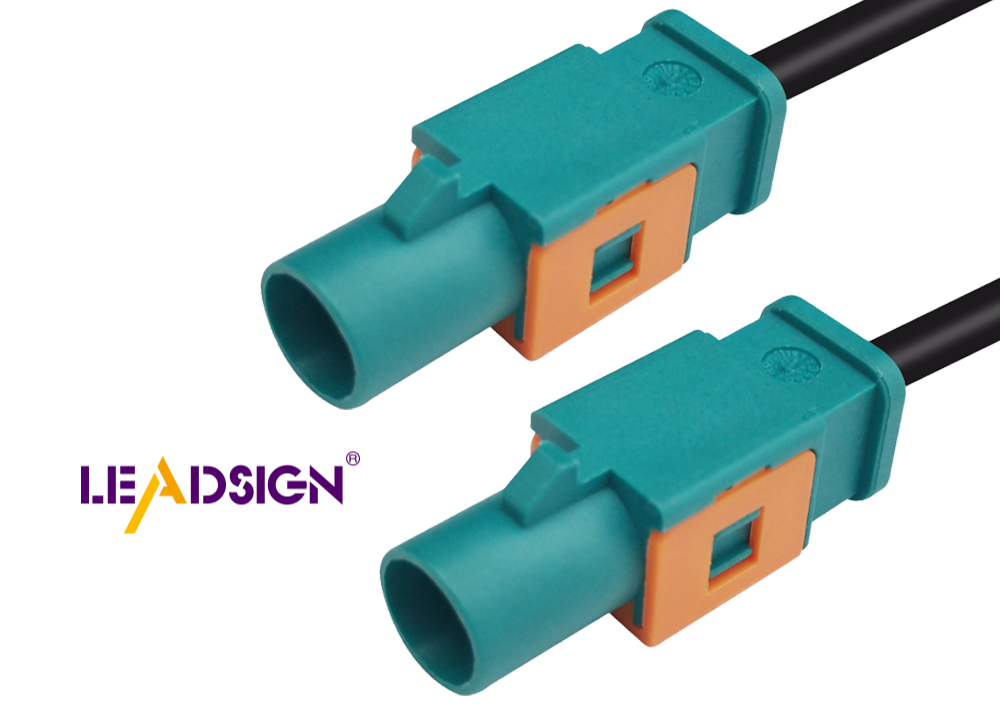

Significance of FAKRA Connectors in Auto Tech

Understanding HSD Connectors in Auto Engineering

Maximizing Auto Data Transfer: Cutting-Edge Connectors and Cables