Understanding and Identifying Vehicle Connectors in Cars

Understanding vehicle connectors is crucial for your car's electrical system. These connectors facilitate the power supply to components like lights and radios. If you mix them up or use them incorrectly, significant problems can arise, potentially affecting your car's performance. Regularly inspecting them helps identify issues early, saving you money on repairs. By learning to recognize and properly utilize these connectors, you ensure your car remains safe and reliable.

Key Takeaways

Understanding vehicle connectors is essential for maintaining your car's electrical system and preventing performance issues.

Regularly inspect and identify connectors to catch potential problems early, saving you money on repairs.

Familiarize yourself with different types of connectors, such as blade, pin, and butt connectors, to ensure proper usage.

Always use the correct connector for each application to avoid electrical failures and enhance safety.

Equip yourself with essential tools like a multimeter and connector pin removal tool to manage connectors effectively.

Avoid common mistakes, such as mixing up connectors or ignoring labels, to maintain a reliable electrical system.

Follow a step-by-step process for changing connectors, including testing them afterward to ensure they function correctly.

Basics of Vehicle Connectors

What Are Vehicle Connectors?

Vehicle connectors are important for your car's electrical system. They connect different parts, letting power and data flow easily. Think of them as the quiet helpers that keep your car's lights, radio, and electronics working well. Without these connectors, your car would have a mess of wires with no clear way for electricity to move.

These connectors come in many shapes and sizes, each made for specific jobs. Some are simple like blade connectors; others are complex like high-speed data ones. The Triton Series connectors are special because they seal well and resist shaking, perfect for electric cars. This variety makes sure every part gets the right power and data it needs to work right.

Why Correct Identification Is Crucial

Knowing vehicle connectors is key to keeping your car safe and working well. Using the wrong one can cause bad connections, leading to electrical problems or damage. You don't want flickering headlights or a cutting-out radio, do you? That's why it's important to know which connector fits where.

Also, safety is very important in cars today. High-quality connectors meet strict safety rules and what people want in safe cars. By using the right ones, you help make your car safer and more reliable. This keeps you and others safe while making your car's electrical system last longer.

Types of Vehicle Connectors

Knowing the different types of vehicle connectors is important for your car. Each type has special features and jobs. Let's look at some common ones you might see.

Blade Connectors

What they look like and how they're used.

Blade connectors are simple vehicle connectors. They have a flat metal piece that fits into a slot. You often find them in cars because they are easy to use and work well. They come in many shapes and sizes, so they can be used for different things.

What They Look Like:

Flat metal piece.

Many sizes and strengths.

Easy to plug in and out.

How They're Used:

Used in lights.

Good for tight spaces.

Great when you need to unplug often.

Blade connectors give a strong link without needing soldering, making them popular in cars.

Pin Connectors

What they are and where they're used.

Pin connectors are another kind you might see. These have pins that fit into sockets, making a strong connection. They are used where a tough connection is needed.

What They Are:

Have pins and sockets.

Make strong connections.

Come in different setups.

Where They're Used:

In engine control units (ECUs).

For sensors.

Good for places with lots of shaking.

Pin connectors handle tough conditions, perfect for important car parts.

Butt Connectors

Their features and uses.

Butt connectors join two wires together end-to-end. They're easy to use and make a strong link without soldering. This makes them great for quick fixes or new setups.

Features:

Simple design to join wires.

No need for soldering.

Come insulated or not insulated.

Uses:

Fix broken wires easily.

Found in car wiring harnesses.

Good for tight spaces too.

Butt connectors keep wires connected well, which is key for your car's electrical health.

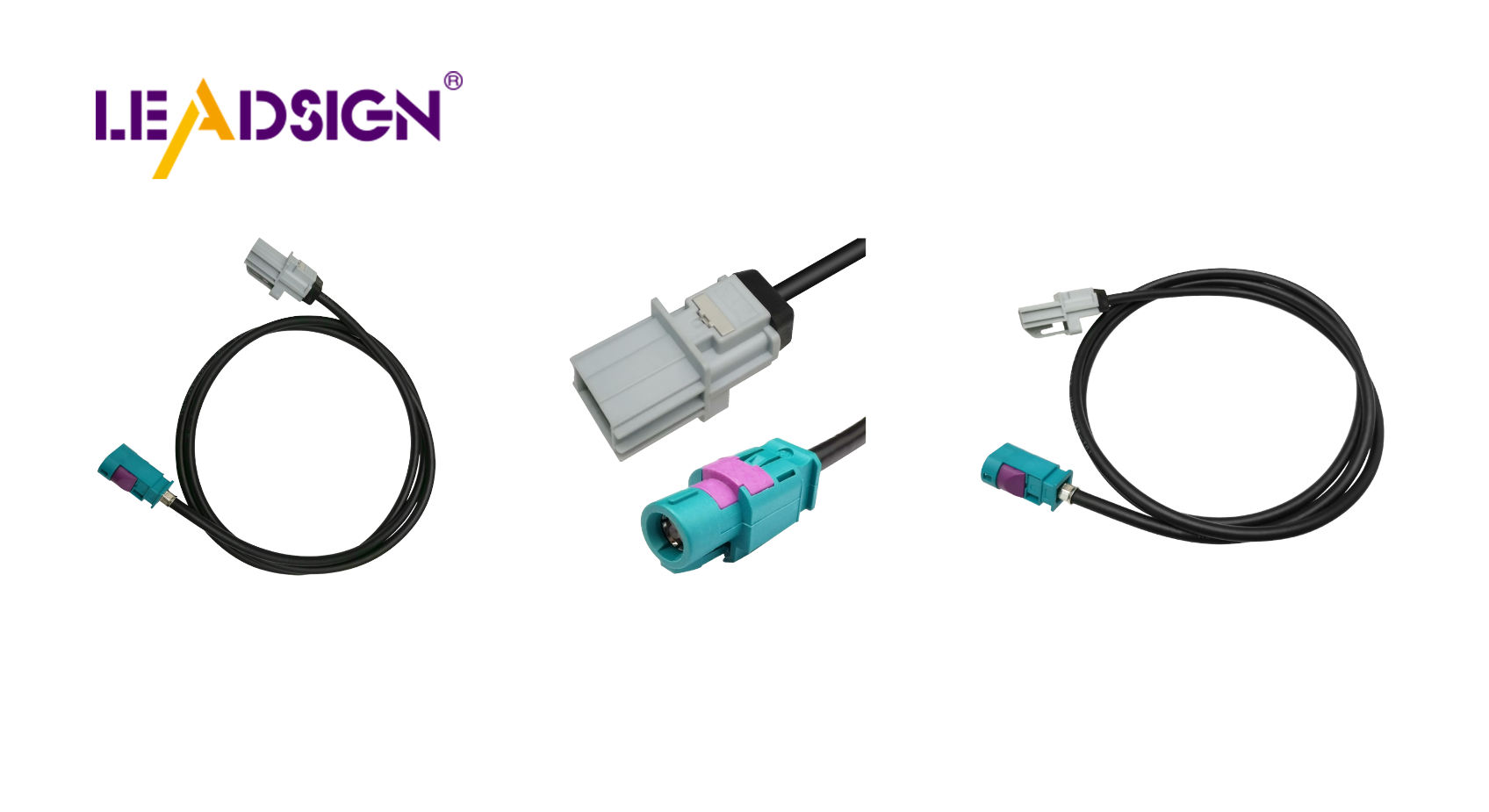

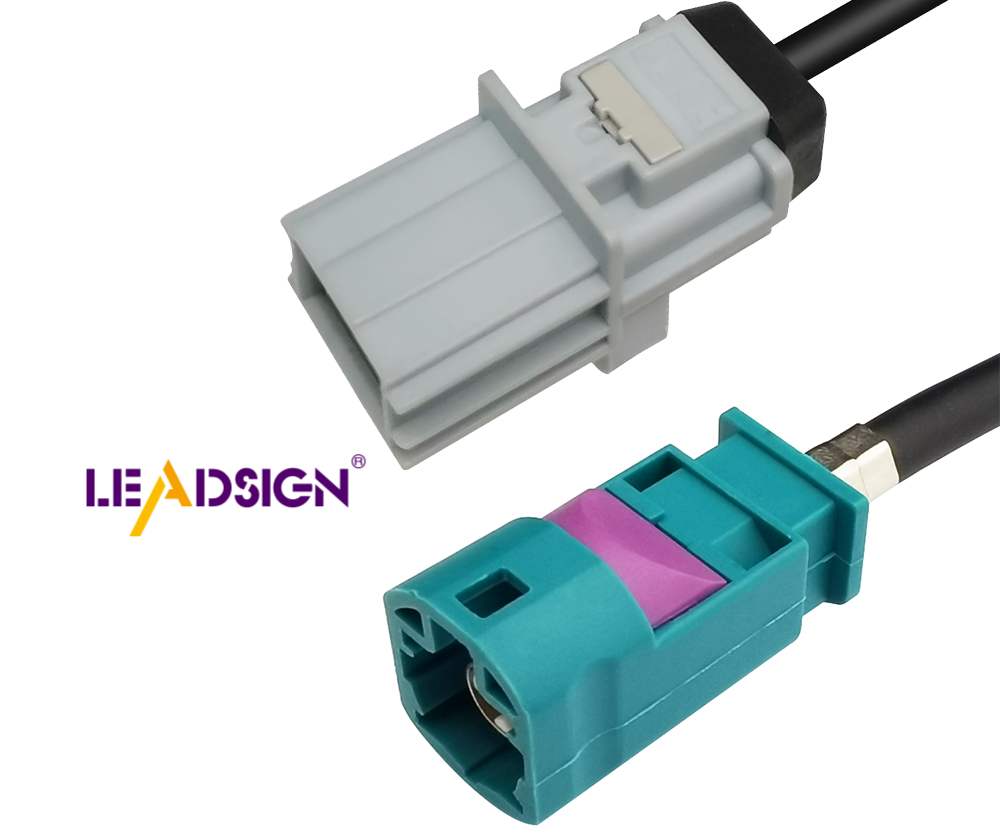

Fast Data Connectors

Fast data connectors are important in today's car electronics. They help your car's screens, cameras, and other digital parts talk to each other well. These connectors move lots of data quickly, which is needed for modern cars.

Uses and Benefits in Car Electronics

Uses:

Screens and Sound Systems: Fast data connectors make sure your music and videos play smoothly while you drive.

Cameras and Sensors: They link cameras and sensors that give real-time info for maps and safety tools.

Digital Networks: These connectors help different electronic systems in your car work together easily.

Benefits:

Quick Data Movement: They send data fast, which is key for car systems needing quick communication.

Strong Build: Made to last in tough conditions, they keep working even when it's rough outside.

Many Uses: Used in things like GPS and driver help systems, they offer design choices.

Clear Signals: They keep signals clear so video and sound stay good quality.

Good Value: Balancing cost with performance, these connectors fit both new cars and upgrades.

Adding fast data connectors makes your car's electronics better. Knowing their uses helps you see how they make driving safer and more fun.

Helpful Tips for Finding Connectors

Finding the right vehicle connectors can save you time and stress. With the right tools and know-how, you can spot and manage these connectors easily. This keeps your car's electrical parts working well.

Tools to Help You

Important tools for finding connectors.

To find vehicle connectors correctly, you'll need some key tools. These help you see details and pick the right connector for each task.

Multimeter: This tool checks if electricity flows in connectors. It shows if a connector is working fine.

Connector Pin Removal Tool: Use this tool to take out pins safely without breaking them. It's useful when changing or checking connectors.

Magnifying Glass: A magnifying glass helps you look at tiny details on connectors. It's good for reading small labels or spotting connector types.

Label Maker: Use a label maker to tag connectors. It helps remember which goes where, especially in tricky systems.

These tools make finding connectors easier and more exact. They help avoid errors and keep your car's electric parts running smoothly.

Mistakes to Watch Out For

Common mix-ups with connectors.

When handling vehicle connectors, mistakes happen easily. Here are some common ones to avoid:

Mixing Up Connectors: Some look alike but do different jobs. Mixing them up can cause bad connections or harm things. Always double-check before connecting them.

Ignoring Labels: Many have labels or marks on them. Ignoring these can confuse you. Always read and follow labels for correct connections.

Forgetting to Test: After connecting, always test it out. Use a multimeter to see if it's working right. This step makes sure everything works as it should.

Skipping Notes: Writing down what you've done helps remember later on. Take notes or pictures of where each connector goes; it's helpful if fixing is needed later.

Avoiding these mistakes keeps your car's electric system steady and reliable by being careful with identifying and using vehicle connectors properly.

Changing Vehicle Connectors

Changing vehicle connectors might seem hard, but you can do it. Let's break it into easy steps to make it simple and stress-free.

Getting Ready

Collecting needed tools and items.

Before starting, gather all tools and items you'll need. This makes the process smooth without stopping.

Tools You'll Need:

Multimeter: Checks if electricity flows in connectors.

Connector Pin Removal Tool: Safely takes out pins without breaking them.

Wire Strippers: Prepares wires for new connectors.

Crimping Tool: Secures new connectors to wires.

Heat Shrink Tubing: Insulates and protects new connections.

Materials to Have:

New connectors matching old ones' specs.

Electrical tape for extra insulation if needed.

Having these ready makes changing connectors fast and easy.

Taking Off and Putting On

Steps to safely remove old connectors.

Now you're ready, let's take off old connectors and put on new ones safely:

Disconnect Battery: Always disconnect the car battery first to avoid shocks or shorts.

20 2. Find the Connector: Use your connector knowledge to find the one to change. Double-check to avoid errors.

Take Off Old Connector:

Use pin removal tool gently on pins.

Pull connector apart carefully, don't harm wires.

Prepare Wires:

Strip wire ends with strippers for fresh wire.

Slide heat shrink tubing over wires before attaching new connector.

Put On New Connector:

Attach new connector using crimping tool.

Ensure it's tight so no loose connections happen.

Secure with Heat Shrink Tubing:

Slide tubing over connection, apply heat for a snug fit.

Follow these steps for safe and effective connector changes.

Testing New Connectors

Ways to test they work right.

After putting them on, testing is key to ensure they work well:

Reconnect Battery: Once done, reconnect car battery.

Use Multimeter:

Set multimeter for voltage or continuity check.

Test new connectors for proper electricity flow.

Check Workability:

Turn on car, test parts linked to new connectors.

Make sure everything works smoothly without flickers or stops.

Testing ensures your car's electrical system stays in great shape with new connectors working fine.

45 You now know how to find and use vehicle connectors. Regular checks keep your car's electrical parts working well. Use these tips for better car performance and safety. Remember, testing connectors can be tough. LEADSIGN-AUTO, a specialist in car connectors, says, "It's hard to know if the issue is with the wire or the connector." Always check your work twice. Stay careful, and your car will run smoothly.

See Also

Why Fakra Connectors Are Essential for Today's Vehicles

Understanding HSD Connectors Within Automotive Applications

A Comprehensive Overview of Ford's Fakra Connectors