Understanding H-MTD Compliance Test Specifications

H-MTD represents a significant advancement in automotive networking. This connector system supports frequencies up to 20 GHz and can transmit data at rates up to 56 Gbps. Compliance test specifications are crucial to ensure that H-MTD adheres to industry standards, guaranteeing its reliable performance and compatibility with other systems. Compliance ensures that the technology functions correctly and safely. The ability to transmit both data and power through a two-wire system enhances energy efficiency, which is vital for emerging automotive technologies such as camera systems and autonomous driving.

Introduction to H-MTD

What is H-MTD?

Definition and background

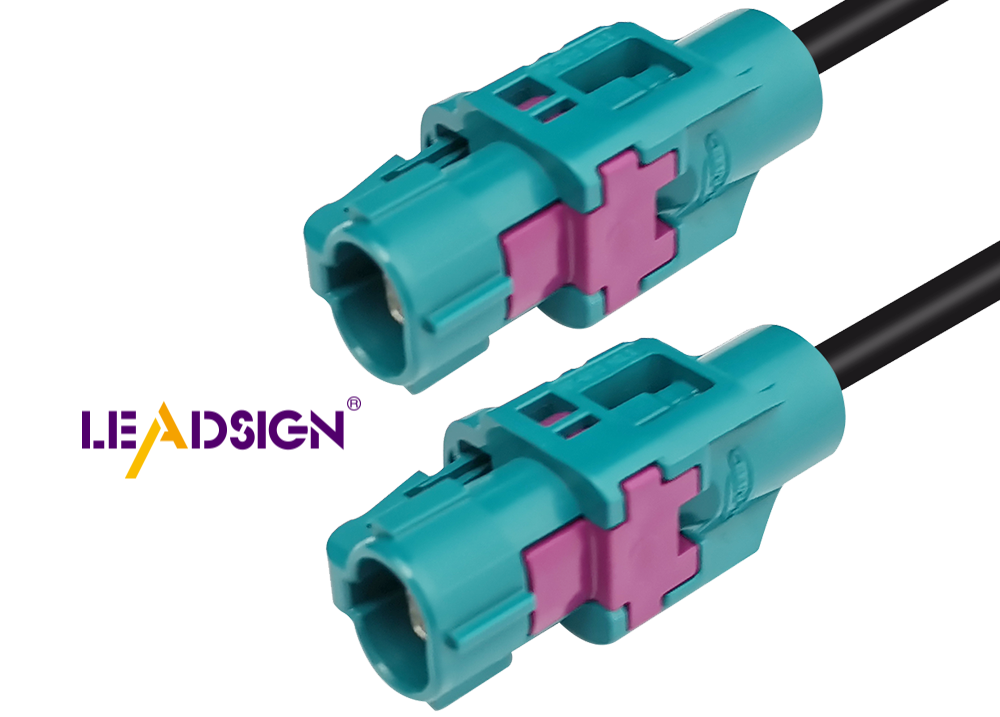

H-MTD means High-Speed Modular Twisted-pair Data. The H-MTD Connector Series is used in cars and factories. It helps with future automation for industrial Ethernet. H-MTD can handle high frequencies up to 20 GHz. It sends data fast, up to 56 Gbps. This makes H-MTD great for modern car networks.

Key features and benefits

The H-MTD system has many important features. The connectors are strong and last long in tough places. They work with different car Ethernet standards like 100BASE-T1 and 1000BASE-T1. The H-MTD connectors send data quickly and reliably. The cable system works well even after tests. These features make H-MTD useful in cars and factories.

Importance in the industry

Current industry standards

Cars need to meet strict rules. H-MTD follows all common car standards, ensuring it works well in cars. Technica Engineering’s switch shows this compliance with strong AVB/TSN abilities and gigabit ports, fitting into current car networks.

Role of H-MTD in innovation

H-MTD is key for new ideas. It supports tech like cameras, driver help, and self-driving cars. Fast data sending and a strong build help these work well. The H-MTD connectors easily add new tech to old car systems, boosting innovation and network function.

Challenges Solved by H-MTD

Common Problems in the Industry

Safety Worries

Keeping car networks safe is hard. Many systems can be hacked. This means bad people might see private stuff. Car makers need strong ways to keep info safe. Checking how well cables and connectors block signals helps with this. Tests by SPE System Alliance show why good blocking is key for safe data.

Working Together Issues

Car Ethernet networks often don't work well together. Different parts must fit perfectly. If not, they can't talk or might break down. Technica Engineering's Enhanced Ethernet Switch H-MTD helps fix this. It supports time sync and AVB functions, solving these problems.

How H-MTD Fixes Things

Better Safety Steps

H-MTD makes car networks safer. Its connectors use special shielding to keep data safe. This stops hackers and keeps data flowing right. Strong H-MTD connectors are great for tough car places.

Better Teamwork

Teamwork between systems is important for cars to work well. H-MTD helps different techs talk easily by supporting many standards. It fits old and new tech together smoothly, helping cars get better with new ideas.

H-MTD Compliance Test Specifications

Overview of Compliance Test Specifications

Purpose and scope

H-MTD tests make sure connectors meet car standards. They check how well H-MTD works in real life. Tests look at data speed, frequency, and strength. Engineers use these to see if connectors work in tough places.

Key components

H-MTD tests have important parts. They check if connectors send data up to 56 Gbps. Frequency support up to 20 GHz is tested too. Strength tests see if connectors last in hard car conditions. They also check if they work with different car Ethernet types.

Testing Procedures

Step-by-step process

H-MTD testing follows steps. First, engineers set up connectors right. Then, they test how fast data moves and frequency support. Next, they test strength under stress. Finally, results show if they meet standards.

Tools and technologies used

Many tools help with H-MTD testing. Special gear checks data speed and frequency support. Chambers create tough conditions for strength tests. Software looks at data and makes reports. Engineers use these for good test results.

Making and Working Together

Using H-MTD in Factories

Best Ways to Do It

Factories need good ways to use H-MTD systems. Engineers should make sure H-MTD connectors fit with car Ethernet rules. This makes sure all car parts talk well. Regular checks are needed to see if connectors meet data and strength standards.

Production teams must keep quality high. They should watch how connectors work during making. Engineers use special tools to check data speed and frequency help. This keeps the H-MTD system working well in different places.

Real-Life Examples

Example: Enhanced Ethernet Switch H-MTD

The Enhanced Ethernet Switch H-MTD works great in cars. It helps manage data better with TSN features like 802.1Qav, Qci, Qbv, and Qbu. The switch shows how well it fits with H-MTD connectors for better performance.

Example: SPE System Alliance Standards

The SPE System Alliance made standard connector faces using IEC 63171-2 and IEC 63171-5 rules. This helps Single Pair Ethernet (SPE) tech work in cars. Their work shows why global rules are important for new ideas.

Teaming Up

Working Together Chances

Working together is key for better H-MTD tech. Car makers and tech companies should team up to make systems better. Joining forces can solve big problems and help put H-MTD into old car designs easily.

Teaming up with research groups gives new ideas about tech changes. These teams help improve data sending and system talking together well. Talking with rule-makers makes sure H-MTD matches new industry needs.

Winning Stories

Winning Story: Technica Engineering

Technica Engineering worked with partners to make car Ethernet better. Their Enhanced Ethernet Switch H-MTD shows what teamwork can do for fast data sending and strong connections.

Winning Story: Global Rule Success

Global rule efforts like those by the SPE System Alliance show teamwork power. These projects helped SPE tech grow in cars and factories worldwide, making things work together everywhere.

H-MTD is important for car networks. It sends data fast and connects well. Technica Engineering’s Enhanced Ethernet Switch shows what H-MTD can do. The future of H-MTD is bright with new SPE tech. These changes will make things quicker and more reliable. Companies should use H-MTD to stay ahead. Working together will help create new ideas. Using H-MTD helps add new tech to cars easily.

See Also

Exploring the World of HSD Connectors

Enhancing Performance with HFM Connectors in Cars

Essential Knowledge on HSD Connectors in Auto Sector