Understanding FAKRA Connectors for Automotive Wire Applications

FAKRA connectors play a crucial role in automotive wire systems, ensuring that connections remain robust and efficient across various applications. These connectors are integral to GPS, music, and safety systems, supporting high-frequency operations up to 6 GHz. Most vehicles are equipped with at least 15 of these connectors, highlighting their importance in maintaining seamless functionality. FAKRA connectors are designed to withstand rigorous use and harsh weather conditions, making them a durable choice for auto wire applications.

What are FAKRA Connectors?

Definition and Purpose

Overview of FAKRA connectors

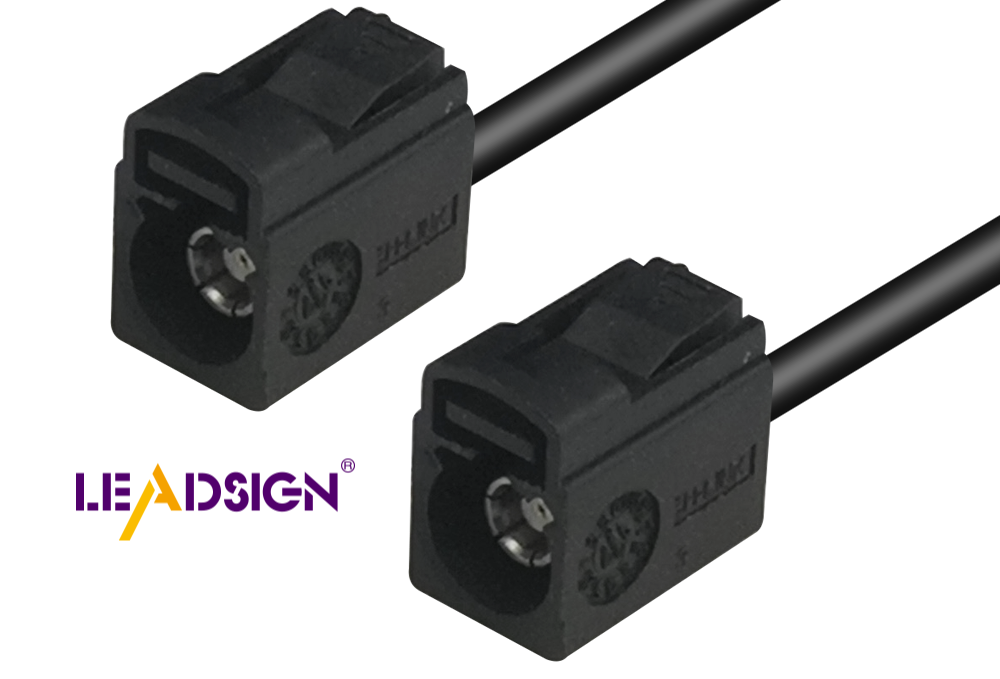

FAKRA connectors are important in car wire systems. They make sure connections work well everywhere. These connectors come from SMB coaxial RF connectors. Rosenberger made them, and later, German car makers standardized them. FAKRA means Working Group Automobile in German. For over 20 years, they have been key in cars.

Key functions in automotive applications

FAKRA connectors help connect many car parts. A typical car has at least 15 of them. They link to GPS, music systems, Bluetooth, and more. They also connect to safety and sensor systems for self-driving features. Their flexibility makes them vital for car wires.

Design and Features

Color coding and mechanical keying

FAKRA connectors use colored plastic covers. This matches the industry rules for color codes. There are 13 different colors and keys to avoid mistakes when connecting. This ensures each connection is safe and works well.

Compatibility with automotive standards

FAKRA connectors meet tough car industry rules. They perform well electrically and mechanically even in bad conditions found in cars. Because they fit these standards, they are a top choice for reliable car communication systems.

Types of FAKRA Connectors

Different Categories

Single connectors

Single FAKRA connectors are used in car wires. They connect one part to another easily. These have a plug and jack inside plastic. This keeps connections safe in cars. Single ones are for simple setups needing just one link.

Multi-pin connectors

Multi-pin FAKRA connectors work in complex car systems. They let many signals go through one spot. This design helps with different car wire uses, making things efficient. Multi-pin ones cut down on many single links, organizing car wires better.

Applications of Each Type

Use in infotainment systems

FAKRA connectors help in entertainment systems. Single ones join radios and speakers. Multi-pin ones handle many signals for big systems. This makes sure everything works well in car wires. Their strong build handles tough car conditions.

Use in safety and navigation systems

Safety and maps need FAKRA for good links. Single ones do jobs like GPS signals. Multi-pin ones help with big systems needing many inputs. This boosts safety features in car wires. Color codes stop mix-ups, making sure links are right.

Benefits of Using FAKRA Connectors

Strong and Lasting

Tough Against Weather

FAKRA connectors are very strong in bad weather. They work well in hot and cold places, from -40°C to +105°C. They keep working even when it's wet, dusty, or shaky. This makes them great for car wires.

Long Life in Cars

FAKRA connectors last a long time in cars. They can be used over 25 times without breaking. Good materials make sure they stay strong for years. This helps important car parts like GPS work all the time.

Easy to Set Up

Simple Plug Design

FAKRA connectors are easy to use in cars. They have colors and shapes that stop wrong connections. Workers can put them in fast without much training or tools.

Fast Setup with Less Mistakes

Putting FAKRA connectors in is quick and easy. Colors and shapes help avoid mistakes when connecting wires. This saves time and money for car makers, making car systems work better.

Installation and Maintenance

Installation Guidelines

Step-by-step installation process

Handle FAKRA connectors carefully. First, find the right color-coded connector. This makes sure it fits correctly. Next, line up the connector with the port. Push it until you hear a click. This locks it in place. Proper alignment stops pin damage and keeps it working well.

Common installation mistakes to avoid

Mistakes can cause connection problems. Don’t force connectors into wrong ports; this can break them. Always check color codes to avoid wrong links. Use gentle force when connecting or disconnecting to keep the lock safe.

Maintenance Tips

Regular inspection and cleaning

Regular checks help FAKRA connectors last longer. Look for wear or damage on plastic and metal parts. Clean with a soft brush or air to remove dust, avoiding strong chemicals that harm materials.

Troubleshooting common issues

To fix problems, find out what's wrong first. If connections fail, check for loose or broken parts. Re-seating might fix small issues. For bigger problems, test signals with special tools and replace bad parts for reliability.

Challenges and Future Trends

Current Challenges

Compatibility with New Technologies

FAKRA connectors struggle with new tech. Cars now use 5G and fast data systems. These need connectors for higher speeds. Old FAKRA handles up to 6 GHz, which might not work. Car makers want better connectors that still fit old ones.

Cost Issues

Cost is a big deal for FAKRA use. Makers try to keep quality cheap. Good connectors cost more to make. The trick is making strong ones without high prices. Car companies look for ways to save money but keep them good.

Future Trends

New Connector Ideas

New ideas in connectors fix problems now. FAKRA-mini is a big step forward. They handle up to 20 GHz and 28 Gb/s data rates. People expect USCAR-49 rules soon for mini coax connectors. These changes help with new car tech needs.

Electric and Self-Driving Cars

Electric and self-driving cars change connector needs. They need lots of data for safety and running well. FAKRA must change for these complex systems in cars. The move to electric pushes the industry to create better ones.

FAKRA connectors are key in car systems. They make sure connections are strong and follow rules. FAKRA connectors are built tough for hard conditions. This makes them a must for high-tech car uses. They can be used in more than just cars. Future car wires will still need these connectors. New ideas will make them even better. FAKRA connectors will help cars talk to each other well in the future.

See Also

Exploring the Significance of FAKRA Connectors in Auto Sector

Unveiling the Role of FAKRA Connectors in Auto Uses

Discovering the Advantages of FAKRA Auto Connectors

The Significance of FAKRA Auto Connectors in Contemporary Cars