Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles, ensuring that electrical components function seamlessly together. If these connectors are faulty, they can cause sparks and lead to damage. Automotive electrical connectors types must withstand harsh conditions such as heat and moisture. Poor-quality connectors can result in unreliable connections and system malfunctions. Therefore, selecting the appropriate type of connector is essential for maintaining vehicle safety and optimal performance.

Overview of Automotive Electrical Connectors Types

Automotive connectors are important for a car's electrical system. Each type has its own job and benefits. Knowing about them helps pick the right one for cars. automotive connectors are important

Blade Connectors

Characteristics and Applications

Blade connectors, also called spade connectors, have a flat end. This end fits into a matching slot easily. They are made from copper or brass, which conduct electricity well. These connectors are used where wires need to be unplugged often, like in fuse boxes.

Common Uses in Vehicles

In cars, blade connectors are found in lights and sensors. They help connect headlights and tail lights. Their simple use makes them liked by car makers and repairers.

Ring Connectors

Characteristics and Applications

Ring connectors have a round end that goes over bolts. They make strong connections using copper alloy, which lasts long. The ring shape keeps them tight even when things shake.

Common Uses in Vehicles

Ring connectors are used on car batteries and grounding spots. They stay attached even in tough conditions, making them key for important connections.

Butt Connectors

Characteristics and Applications

Butt connectors join two wires together at their ends. They create a lasting link between wires. Made from materials like copper, they resist rusting well.

Common Uses in Vehicles

In cars, butt connectors fix or extend wire harnesses. They ensure signals pass through without stopping. Mechanics use them to add new parts or fix broken wires.

Pin Connectors

Characteristics and Applications

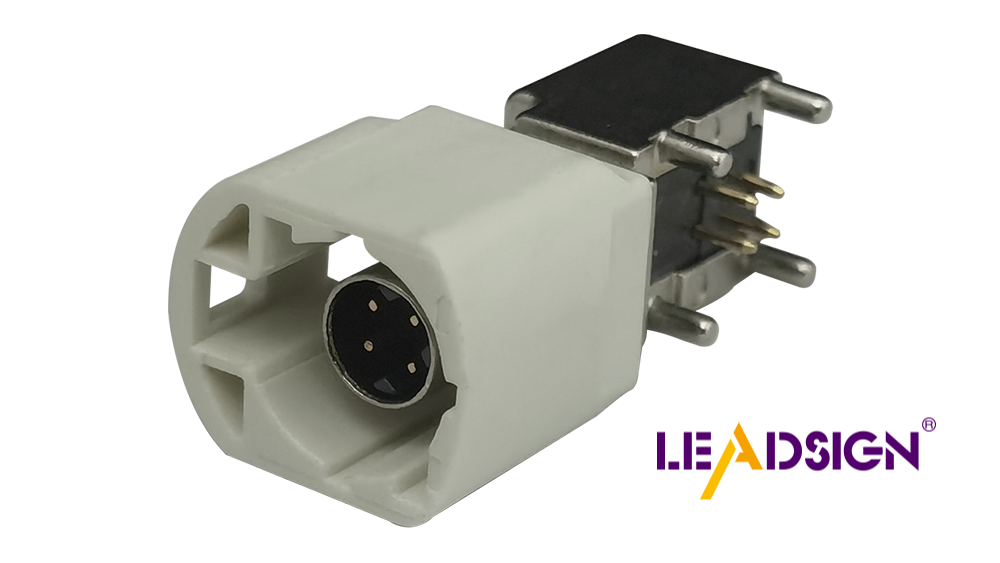

Pin connectors are important in car electrical systems. They have a round pin that fits into a matching hole, making a strong connection. These connectors often use copper alloy, which is tough and resists problems like bad contact or getting too hot. Bimetallic connectors are pin connectors that fight rust well. By mixing materials like copper and aluminum, they stop rust better than regular ones.

Common Uses in Vehicles

In cars, pin connectors are used where many wires need to connect safely. They are key in engine systems and electronic control units (ECUs). Pin connectors help signals and power move well between parts, keeping the car working right. Their strong build makes them good for rough places with shaking and heat changes. Mechanics trust pin connectors to keep important car systems connected.

Things to Think About When Picking Connectors

Picking the right car connectors needs knowing some important things. These make sure connectors work well and safely in cars.

Electrical Needs

Current and Voltage Levels

When picking connectors, check current and voltage levels. Each connector type handles certain electric loads. For example, Pin Connectors manage different currents, making them good for many car uses. Matching the connector to the system's electrical needs stops overheating and problems.

Environment Factors

Connectors should handle changes like temperature shifts, wetness, and chemicals. VH Connectors show why matching with the environment matters. Picking connectors made from rust-proof materials ensures they last long. This is key in cars where connectors face tough conditions.

Mechanical Needs

Strength and Material

A connector's strength comes from its building materials. High-Voltage Aerospace Connectors show why strong materials are needed for lasting use. In cars, connectors made from tough stuff like copper alloys resist damage. This strength keeps connections safe over time.

Size and Fit

Size and fit are big parts of choosing connectors. They must fit into the system without causing trouble. VH Connectors show why picking matching plugs is important to avoid contact issues. Making sure connectors fit right prevents setup problems and boosts system work.

Best Ways to Install Connectors

Installing car connectors right makes them work well and safely. Doing it the best way stops problems like bad contact or system breaks. Here’s how to install them properly.

How to Crimp Right

Crimping is key when putting in connectors. It means pressing a connector onto a wire with a tool. Good crimping makes sure the connection is strong and works well.

Tools You Need

To crimp well, use the correct tools. Important ones are:

Crimping Tool: Pick one that fits your connector type. A ratchet crimper gives even pressure.

Wire Stripper: This tool takes off insulation without hurting wires.

Heat Gun: For heat shrink connectors, this gun seals tightly.

Easy Steps to Follow

Strip the Wire: Take off about 1/4 inch of insulation with a wire stripper.

Insert the Wire: Put the bare wire into the connector barrel.

Crimp the Connector: Place it in the crimper tool and squeeze hard.

Check the Crimp: Make sure it's tight and won't let go easily.

Use Heat: If using heat shrink, warm it evenly until it seals.

Keeping Connections Strong

Strong connections make car systems last long and work well. Testing and care help keep them strong. Fix connection problems.

Test and Check

After installing, test to see if connections are good. Use a multimeter for continuity checks and resistance levels. Make sure they meet needed specs to find weak spots early.

Care Tips

Regular care keeps connectors working great. Try these tips:

Look Often: Check for wear, rust, or damage on connectors.

Clean Contacts: Use cleaner to get rid of dirt on surfaces.

Tighten Up: Keep all connections tight over time.

Swap Bad Parts: Change out worn or damaged connectors to avoid issues.

Research Findings: Picking good connectors is key for safe electric systems in cars. Think about material, size, cable type, and rust effects.

By following these tips, car connectors will work reliably, keeping vehicles safe and efficient electrically.

Choosing the correct connector is important for keeping car electrical systems working well. Each connector has a special job to make sure parts work together smoothly. Regular inspection and maintenance help stop problems like rust or metal damage. Experts say to use connectors that fight these issues, such as bimetallic ones. By following good installation and care tips, people can make their car's electrical systems last longer and work better. Focusing on quality and taking care of them keeps cars safe and efficient on the road. Maximize wire functionality.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System