Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components for vehicles. They play a vital role in ensuring that connections function properly, which is essential for the smooth operation of various car parts. Without these connectors, automobiles would encounter numerous electrical issues. It is worth noting that automotive connectors are more prone to failure compared to aircraft wires, underscoring their significance in vehicle functionality. There exists a wide range of automotive electrical connector types, each designed to cater to specific requirements and scenarios. These connectors facilitate the flow of electricity and provide protection against environmental elements, thereby ensuring optimal vehicle performance and long-term safety.

Basic Ideas of Car Wiring Connectors

What are wiring connectors?

Wiring connectors are important parts in cars. They link electrical circuits, letting electricity move easily between car parts. These connectors help lights, sensors, and control units work right. Without them, the car's electrical system might break down.

Why are they important in cars?

Cars need wiring connectors to work well. They make strong connections that handle shakes and weather, keeping things reliable. Connectors also make fixing easier for mechanics without much rewiring. This saves time and makes cars run better.

Common Materials Used

Metal connectors

Metal connectors, like copper or gold ones, carry electricity well. They have little resistance for good power flow. These connectors last long even in heat or rust. They're great for important jobs where trust is key.

Plastic connectors

Plastic connectors made from nylon or similar stuff are light and cheap. They stop electric shorts and keep things safe with good insulation. Plastic can be shaped easily to fit different designs. They're useful for many car uses.

Automotive Electrical Connectors Types

Car connectors come in many types. Car connectors come in many types. Each type has a special job in cars. Knowing them helps pick the right one for good car work.

Blade Connectors

Characteristics and uses

Blade connectors look like flat blades. They slide into slots easily. This makes them perfect for quick fixes, like in fuse boxes.

Advantages and disadvantages

Advantages:

Easy to use: Blade connectors are simple to put on and take off.

Versatile: They fit different parts, making wiring flexible.

Disadvantages:

Low current limit: They can't handle big power loads well.

Can disconnect: Shaking can make them come loose sometimes.

Pin Connectors

Characteristics and uses

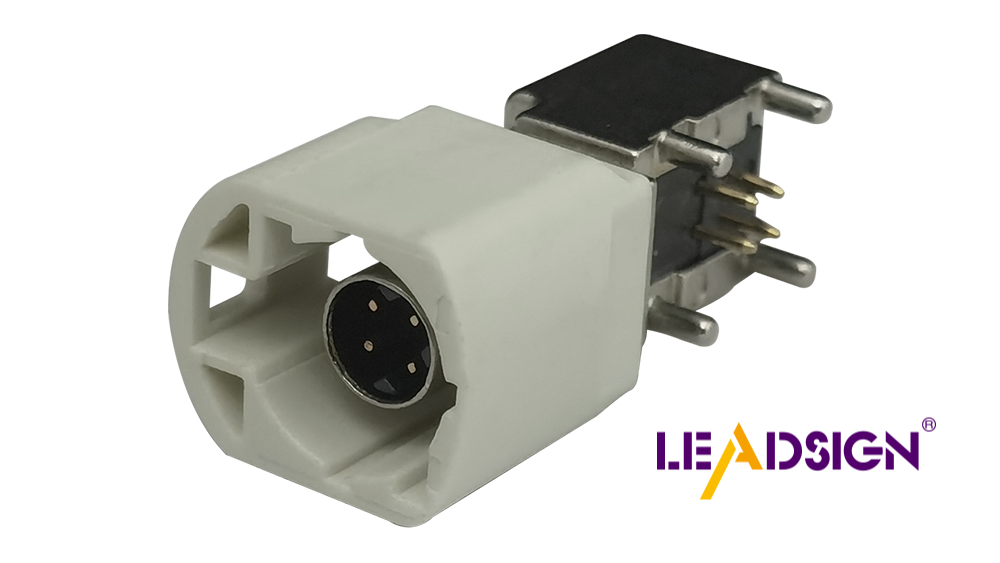

Pin connectors have pins that go into sockets. They're used where strong links are needed, like in engines.

Advantages and disadvantages

Advantages:

Strong link: Pins stay connected even if things move.

Many connections possible: They fit lots of wires in small spaces.

Disadvantages:

Hard to install: Lining up pins is tricky in tight spots.

Gets dirty easily: Dirt or water can mess up the connection.

Butt Connectors

Characteristics and uses

Butt connectors join two wires end-to-end. They're great for fixing or changing wires without soldering.

Advantages and disadvantages

Advantages:

Simple to use: Easy way to join wires with few tools.

Has insulation: Protects from weather problems.

Disadvantages:

Not flexible once joined: Can't separate wires without cutting.

Weak links possible if crimped wrong

Knowing these connector types helps fix cars better. Picking the right one keeps car systems safe and working well.

Ring and Spade Connectors

What They Are and How They're Used

Ring and spade connectors are important in car electrical systems. They keep connections safe and working well. Ring connectors have a round end with a hole. You can attach them tightly with a screw or bolt, so they don't come off by accident. They're used where you need a strong link, like for grounding wires or battery ends.

Spade connectors look like forks. They easily go on and off screws or bolts. This makes them good for places where you might need to disconnect often, like switches.

Good and Bad Points

Good Points:

Strong Links: Ring connectors hold tight, so things stay connected.

Easy to Use: Spade connectors are simple to put on or take off.

Can Fit Many Wires: Both types work with different wire sizes.

Bad Points:

Hard to Remove Quickly: Ring connectors need tools to take off.

Might Get Loose: Spade connectors can wiggle loose over time.

Knowing about ring and spade connectors helps pick the right one for cars. The right choice keeps car parts working well for a long time.

Picking Wiring Connectors

Choosing the right car connectors needs knowing electrical and mechanical needs. This makes sure they work well in different situations.

Electrical Needs

Current and Voltage

Connectors must handle the car's current and voltage levels. High-current jobs need connectors with low resistance to stop overheating. For example, ring terminals give a strong connection point, keeping wires attached even with high current. Picking connectors that fit the system's electrical needs stops problems and boosts performance.

Environment

Cars face tough conditions like moisture, dust, and temperature changes. Connectors should resist these to stay reliable. Sealed connectors block out dirt and water, ensuring they work long-term. Choosing connectors with good sealing and insulation keeps systems working well.

Mechanical Needs

Strength and Reliability

Connectors must handle vibrations and hits. Strong materials like metal or good plastics make them last longer. Ring and spade terminals, known for being tough, give strong connections that last through wear. Picking durable connectors cuts down on repairs and makes the car's electrical system last longer.

Easy to Install

Easy installation is key for quick fixes and maintenance. Connectors that attach fast save time and cut mistakes. Spade connectors, with their fork shape, make connecting easy where you need frequent access. Choosing easy-to-install connectors improves overall car service.

Practical Uses and Things to Think About

Best Ways to Install

Tools and How to Use Them

Putting in car wiring connectors right makes them work well. Workers need the right tools, like crimpers and wire strippers, for good connections. Crimpers press the connector tight on the wire. Wire strippers take off insulation without hurting wires. Using these tools stops loose wires or electrical problems.

Ways to Do It:

Crimping: Press hard for a strong hold.

Stripping: Take off just enough cover to show the wire.

Soldering: Soldering adds strength, especially where things shake a lot.

Mistakes People Make

Avoid mistakes when installing to save time and stop issues later. A common mistake is picking the wrong connector type. Each one has its job, so using the wrong one can cause trouble. Bad crimping makes weak links too. Also, keep connectors dry unless they are sealed types.

Mistakes Not to Make:

Wrong connectors used: Match connector type with its job.

Bad crimping: Make sure crimps are tight.

Wet connectors exposed: Use sealed ones in wet places.

Fixing and Checking Problems

Finding Bad Connectors

Regular checks find bad connectors before big problems happen. Signs of bad ones include flickering lights, rust, or damage you can see. Look at connectors for wear or broken parts like pins or loose bits. A multimeter helps check if they work right.

Signs of Bad Connectors:

Flickering lights or power loss: Look for loose parts.

Rusty spots: Check metal parts for rust.

Broken pieces seen: Look for bent pins.

Tips on Fixing or Changing Them

If a connector breaks, fix it or swap it out. For small issues, cleaning with contact cleaner might help it work again. If it's too broken, get a new one that matches old specs to keep things working well.

Fix and Swap Tips:

Clean up dirt and rust with cleaner

Get new ones matching old specs

Test after fixing to make sure it works

Knowing how car wiring connectors work helps them last longer and stay safe. By doing things right and avoiding mistakes, workers keep car electrical systems running smoothly.

Car wiring connectors are very important for car safety and working well. They keep electricity flowing, stopping big problems in important parts like steering and brakes. Picking the right connector means thinking about how it keeps circuits safe and stops contact problems. Handling them carefully and putting them in right stops damage, making sure they last long. Knowing these things helps people choose better, making cars work better and safer.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors