Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles, ensuring reliable electrical connections that are essential for systems to operate smoothly. These connectors prevent issues by maintaining stable connections even under challenging conditions. The failure rates of different automotive electrical connectors types vary depending on factors such as temperature and the power they handle. For instance, a four-pin connector with rubber inserts can manage specific power levels, reducing the likelihood of failure. Understanding these automotive electrical connectors types aids in selecting the appropriate one for each task, enhancing the safety and efficiency of car systems.

Types of Car Electrical Connectors

Knowing different car electrical connectors is important for fixing or designing cars. These connectors help car systems work well and safely. They are grouped by what they do, how they look, and what they're made of.

By What They Do

Power Connectors

Power connectors move electricity in a car. They handle big currents and voltages, so they connect batteries and other strong parts. High-voltage connectors for EVs help charge electric cars fast. They focus on safety and better performance.

Signal Connectors

Signal connectors send small electric signals in a car. They are key for sensors and controls to share data correctly. Bullet connectors are used in car radios to keep signals steady. Their parts fit together tightly.

Data Connectors

Data connectors are more needed now with new tech like infotainment systems and ADAS in cars. High-speed data connectors make data move fast, helping with car networks. They keep new tech working well.

By How They Look

Male and Female Connectors

Male fits into female parts to make many car connections secure. This design is common in wire connectors, which join circuits in a car's system.

Sealed and Unsealed Connectors

Sealed ones block water and dust, good for tough spots. Unsealed ones go where it's not as harsh. Choosing depends on where they'll be used.

By What They're Made Of

Plastic Connectors

Plastic ones are light and don't rust, good for many uses in cars needing less weight but still protect from the environment.

Metal Connectors

Metal ones like copper or brass are strong with great electricity flow, used where strength is key against stress or heat.

Knowing these types helps pick the right connector for each job, keeping cars safe and working well.

Characteristics of Automotive Wiring Connectors

Knowing about car wiring connectors is important. It helps cars work well and safely. These features show how good connectors are for different jobs.

Electrical Properties

Current Rating

Connectors need to handle different currents. The current rating shows the most current a connector can carry safely. Picking the right one stops electrical problems and keeps things working well.

Voltage Rating

Voltage rating tells us how much voltage a connector can take. High-voltage ones are key in electric cars for fast charging and power transfer.

Mechanical Properties

Durability

Durability matters a lot for car connectors. They must handle stress, shaking, and being unplugged often. New designs make them last longer and work better.

Temperature Resistance

Connectors face hot or cold temperatures in cars. They need to resist these to work right in all weather.

Environmental Properties

Water Resistance

Water resistance is needed where there’s moisture or water. Sealed ones stop water from causing short circuits or rusting.

Corrosion Resistance

Rust can hurt connectors' performance. Using special metals or coatings helps them last longer without rusting.

Scientific Research Findings: Studies say picking connectors that handle heat, wetness, and dirt is important for long-lasting use in cars.

Choosing the right connector based on these traits makes cars safer and better performing. Understanding these helps pick the best fit for modern car systems.

How to Install Car Wiring Connectors

Installing car wiring connectors right is important. It makes sure electricity flows well and safely.

Tools You Need

You need special tools for this job:

Crimping Tools

Crimping tools press connectors onto wires. This makes them stay together strong. Different connectors need different crimping tools.

Soldering Tools

Soldering tools join wires with melted metal. This makes a strong link that lets electricity pass. You use soldering irons and solder wire for this.

Steps to Install Connectors

Follow these steps to do it right:

Getting Wires Ready

Take Off Insulation: Use a tool to strip off some plastic from the wire ends. This shows the metal inside.

Twist Wire Ends: Twist the metal strands so they don’t come apart. This keeps them neat and tight.

Putting on Connectors

Pick a Connector: Choose one that fits your wire size and needs.

Crimp or Solder: Use crimpers if you want to crimp, or heat up the solder iron to melt solder for joining.

Check Connection: Look at it closely to see if it's tight with no loose parts.

Testing Your Work

Look Closely: Check if everything looks good and lined up right.

Test Electricity Flow: Use a multimeter to see if electricity moves through well without problems.

Pro Tip: Check connectors often so they don't wear out or get damaged by weather.

By doing these steps and using the right tools, you can make sure car wiring works well for a long time.

Industry Trends and FAQs

New Trends

Smaller Connectors

In cars, making connectors smaller is a big trend. Tiny connectors save space and make cars lighter. This is important for new cars. They let more parts fit in small spaces without losing power. As cars get smarter, we need more small automotive electrical connectors types. These tiny ones work like big ones but are better for design.

Smart Connectors

Smart connectors are another cool trend. They use tech to make car systems better. They can check themselves and tell if there's a problem right away. This helps fix things before they break down. Smart connectors keep car systems safe by making sure connections stay strong.

Common Questions

How to pick the right connector?

To pick the right connector, know what your car needs. Connector Experts say choosing the best automotive electrical connectors types keeps your car working well and safely. The right one moves power and signals smoothly in your car. Think about things like current, voltage, weather, and what it's made of when picking one. A good choice makes your car last longer.

What problems do connectors have?

Common problems with automotive electrical connectors types are rust, bad links, and wearing out over time. Rust happens from water or weather, making them work less well. Bad links come from wrong setup or using the wrong type, causing electric issues sometimes. Checking often can stop these troubles. Connector Experts say to swap old parts with correct ones for a strong link in your car's system to avoid breakdowns.

Choosing the right car connectors is very important. They help cars work well and stay safe. Connectors link different parts, like radios and engines. Using the right ones makes cars last longer and work better. As cars get more advanced, connectors must improve too. This needs ongoing research and new ideas. The future for car connectors is bright, with a focus on being reliable and efficient. Checking them often stops problems, keeping cars safe and working well.

See Also

Exploring HSD Connectors in the Automotive Sector

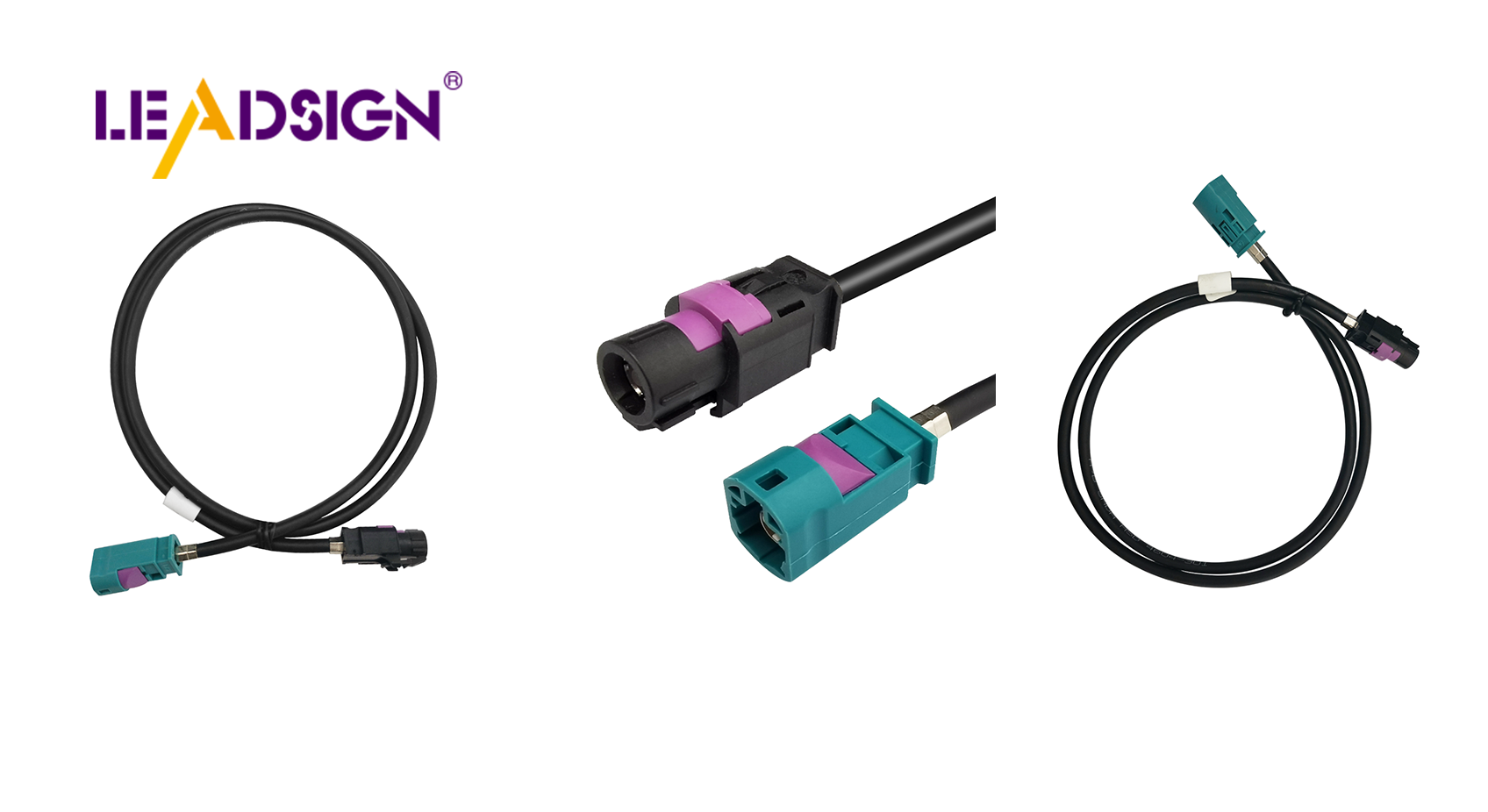

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors