Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components in modern vehicles. They play a vital role in connecting various electronic components securely. These connectors ensure the proper functioning of systems such as lighting, audio, and engine controls. There exist various types of connectors, each designed for specific purposes. Some connectors allow for easy disconnection, while others provide protection against water ingress. Understanding the different automotive electrical connectors types is essential for maintaining the safety and optimal performance of vehicles.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car systems. They link electrical circuits, allowing electricity to flow smoothly. These connectors come in different types like pigtail connectors, terminal blocks, and bullet connectors. Each type has a special job connecting wires, sensors, switches, and modules in cars.

Importance in Automotive Systems

In cars, wiring connectors are very important. They make sure electronic parts work well. Without them, things like lights, music systems, and engine controls wouldn't work right. By keeping connections secure, they help keep cars safe and working well.

Basic Components of Connectors

Terminals

Terminals are the main part of any connector. They carry electricity between wires and parts. Common ones include crimp connectors and spade terminals. These terminals keep the electrical connection steady for car systems to work efficiently.

Housings

Housings shield the terminals and wires from outside elements. They stop moisture and dirt from messing up the electrical link. Housings also give support so that connectors stay together when cars move. Different shapes like square or round fit different uses.

Seals

Seals make connectors last longer by adding extra protection. They stop water and dirt from getting to the terminals. This is crucial in tough conditions where exposure can harm connections. Seals help keep connectors reliable over time, aiding car system durability.

Types of Automotive Electrical Connectors

Automotive electrical connectors types are important for cars to work well. They help electricity move between parts, keeping the car running. Knowing about these connectors is key for fixing or taking care of cars.

Blade Connectors

Features and Applications

Blade connectors, also called spade connectors, are flat and thin. They connect wires easily and can be disconnected fast. Their shape keeps them secure, so they don't come apart by accident. Blade connectors are used when you need to disconnect often.

Common Uses in Vehicles

In cars, blade connectors link things like headlights and tail lights. They're also in audio systems and dashboards. Because they're simple to use, both mechanics and DIY fans like them.

Pin Connectors

Features and Applications

Pin connectors have pins that fit into sockets. They give a strong connection and are used in complex systems. Pin connectors handle many connections at once, good for tricky wiring.

Common Uses in Vehicles

Pin connectors are in engine control units (ECUs) and other key systems. They make sure signals go right between car parts. Their tough build works where there's lots of shaking.

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end safely. They keep water out by being insulated well. You crimp them onto wires for a tight hold.

Common Uses in Vehicles

In cars, butt connectors fix or extend wires. They're vital for keeping the car's electric system safe from problems.

Expert Testimony: An expert said, "Connectors let electricity flow between electronic parts." This shows why picking the right automotive electrical connectors types is important.

Knowing different automotive electrical connectors types helps anyone working with car electronics do their job better.

Specialty Connectors

Features and Applications

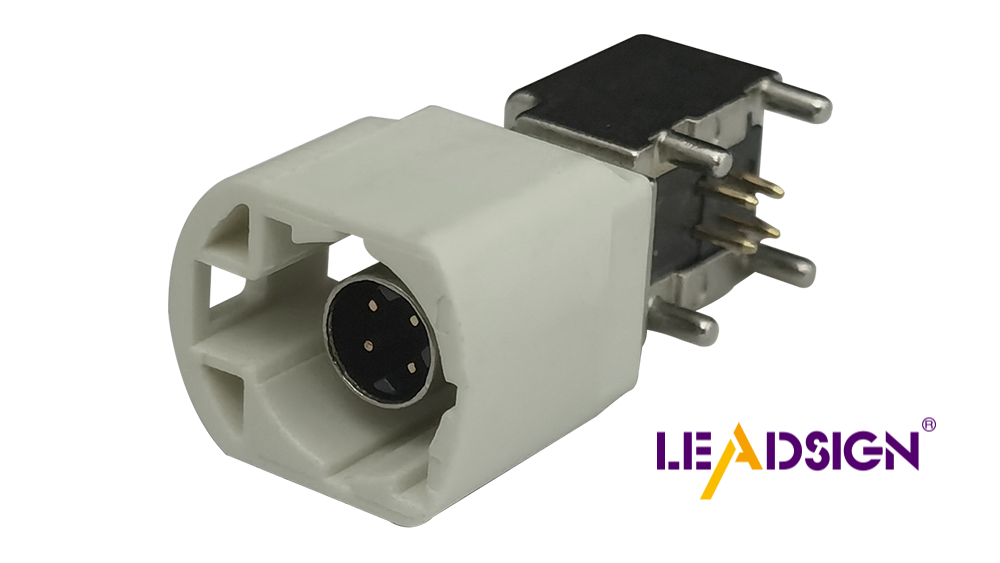

Specialty connectors are unique among automotive electrical connectors types. They have special features for certain car needs. Some handle fast data, perfect for fancy screens and maps. Others are tough, resisting heat or rust.

Expert Testimony:

An electronics expert says, "Connectors let signals move between parts." This shows how specialty connectors keep car systems working well.

These connectors often lock tightly to stay connected in rough spots. They might also have codes to stop wrong hookups. They're key in modern cars where being exact is important.

Common Uses in Vehicles

In the world of automotive electrical connectors types, specialty ones are used a lot. They're needed for fast data, like with cameras and sensors. Fast data connectors help safety systems work quickly.

Specialty connectors are also common in electric cars. These need to handle lots of power safely. They connect parts inside the battery system, helping the car run safely and well.

How to Install Connectors Right

Tools You Need

Crimping Tools

Crimping tools are important for strong wire connections in cars. They squeeze the connector onto the wire tightly. Mechanics use them to keep electrical systems working well. A good crimping tool can change settings for different sizes.

Soldering Equipment

Soldering equipment makes wires and connectors stick together forever. It melts metal to join parts. This is good where shaking might loosen other connections. Soldering irons and solder wire are part of this setup.

Easy Installation Steps

Getting Wires Ready

Take Off Insulation: Use a stripper to remove half an inch of insulation from wire ends. This shows the metal core for connecting.

Twist Wire Ends: Twist the bare strands together so they don't fray. This helps make a neat connection.

Connecting Wires

Pick the Right Connector: Choose a connector that fits the wire size and job. Special connectors might be needed for some tasks.

Put in Wire: Insert stripped wire into connector snugly, with no loose strands.

Crimp or Solder: Use crimper or solder iron to secure it. Crimp by squeezing; solder by melting metal to bind.

Making Sure Connections Are Safe

Look at Connection: Check for loose wires or bad crimps. A strong connection should not come apart easily.

Test Circuit: Use a multimeter to check if electricity flows right.

Mistakes People Make

Too Much Crimping

Too much crimping can hurt wires and connectors, making them break or weak. Always use correct pressure for each type.

Wrong Wire Stripping

Wrong stripping leads to bad connections—too much exposes wires, too little stops proper linking. Measure and strip just right length.

Expert Insight: "Good installation keeps car electrical systems lasting long," says an expert, showing why following steps is key in wiring work.

Picking the right connector is key for car safety and performance. Each connector has a special job, making sure systems work well. Using good methods during setup makes them last longer. Correct steps stop problems like squeezing too hard or stripping wires wrong.

Connector Maker says, "Ask experts to find the right fit for cars." This shows why expert help is important when choosing connectors.

Good wire connections greatly affect how a car works. They help electronic parts run smoothly, boosting overall car efficiency and safety.

See Also

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System