Understanding Automotive Wiring Connector Types

Cars rely on various automotive electrical connectors types to function properly. These connectors play a crucial role in ensuring the car's electrical system operates efficiently, which is essential for both safety and performance. Malfunctioning connectors can lead to electrical components failing, posing potential hazards. There is a wide range of automotive electrical connectors types available, each designed for specific purposes and environments. Selecting the appropriate connector is key to ensuring optimal functionality, as factors like connector type and heat resistance can impact their reliability. Understanding the different types of connectors is vital for maintaining the overall health of cars.

Types of Car Electrical Connectors

Car electrical connectors help cars work well. Each types of car electrical connectors has special jobs and benefits. Knowing them helps pick the right one for car tasks.

Blade Connectors

What They Are and How They're Used

Blade connectors, also called spade connectors, are flat metal pieces that fit into slots. They're used in cars because they are easy to use and reliable. These connectors join wires to things like switches and relays. Their design makes connecting and disconnecting fast, which is good for places needing lots of fixing.

Good and Bad Points

Blade connectors have many good points. They connect well and are simple to put in without special tools. But they might not stay tight in shaky places as they can get loose over time. Also, they may not keep out water or dirt as well as other types.

Pin Connectors

What They Are and How They're Used

Pin connectors have pins that go into matching holes. They're used a lot in cars because they handle many connections in small spaces. You find them in engine parts where exact connections matter.

Good and Bad Points

Pin connectors make strong links for many wires, so they're useful. They resist weather changes, making them last longer. But putting them in can be tricky since the pins must match up right, which takes more time than other types.

Butt Connectors

What They Are and How They're Used

Butt connectors are tube-shaped pieces joining two wire ends together. They make strong links for car wiring that last long. You can get them with or without covers depending on what you need.

Good and Bad Points

Butt connectors easily join wires with a crimping tool for a solid link but aren't great if you need to unplug often. Ones without covers might let water in, causing rust later on.

Rules and Details

Knowing the rules for automotive electrical connectors is important. These rules make sure connectors are safe and work well. They also keep things the same in different car systems.

Industry Rules

Industry rules help design and use Industry rules help design automotive electrical connectors. They give a plan for makers to follow, so parts fit and work right.

ISO Rules

The International Organization for Standardization (ISO) makes world rules for many things, like cars. ISO rules for automotive electrical connectors make sure they are safe and good everywhere. For example, ISO 15031-3:2016 matches European car check needs. This rule changed a connector type for cars with 24 V systems. Such rules make sure connectors work well in all kinds of car places.

SAE Rules

The Society of Automotive Engineers (SAE) also makes rules for automotive electrical connectors. SAE rules ensure that these parts can handle tough car conditions. They talk about how long they last, how they handle electricity, and how strong they are against weather. By following SAE rules, makers create parts that are both strong and useful.

Connector Details

Details about automotive electrical connectors say what materials and electric features they need to work best. These details help makers build parts that meet what the industry wants.

Material Details

Material details tell what stuff to use so connectors stay strong in different weathers. Connectors should not rust or break from heat or pressure. Good materials keep them working well over time, lowering failure chances. Makers often pick copper or aluminum because they carry electricity well and last long.

Electrical Details

Electrical details show how automotive electrical connectors should perform with electricity. This includes how much power they carry, voltage limits, and resistance levels. Right electric details mean connectors can handle modern car power needs without problems like overheating or shorts.

By knowing the rules and details for automotive electrical connectors, makers and repairers can make sure these parts work right every time. This helps choose the best ones for each job, making cars safer and better.

Picking the Right Connector

Choosing the right car wire connectors is important. It helps the car's electric parts work well. Many things affect this choice, and knowing them helps make smart picks. Choosing the right car wire connectors is important. It helps the car's electric parts work well. Many things affect this choice, and knowing them helps make smart picks.

Things to Think About

Weather Conditions

Weather matters when picking car wire connectors. They must handle hot, cold, wet, and dusty places. For example, engine connectors need to be tough against heat and fluids. Copper or aluminum are good choices because they last long and don't rust easily. Strong connectors stop problems and keep systems working.

Power Needs

Power needs are also key. Different connectors handle different power levels. It's important to match the connector with the car's power needs. High-power spots need connectors that won't overheat. Knowing these needs helps pick safe and strong connectors. Different connectors handle different power levels. It's important to match the connector with the car's power needs. High-power spots need connectors that won't overheat. Knowing these needs helps pick safe and strong connectors.

Mistakes to Watch Out For

Ignoring Fit

A big mistake is ignoring fit. Not all connectors work everywhere in a car. Make sure they fit right with current systems. Wrong fits can cause bad links and failures. Always check if the connector matches what you have.

Skipping Quality Checks

Skipping quality checks causes trouble too. Good connectors follow rules like ISO and SAE for safety and performance. Cheap ones might fail often, costing more later on repairs. Picking quality means safer, longer-lasting systems.

Picking good car wire connectors means thinking about weather and power needs carefully. Avoiding mistakes like wrong fits or low quality improves how long a car's electric system works well.

Choosing the right car wire connector is very important. It helps cars work well and stay safe. Each connector has a special job. Knowing these jobs helps you choose wisely.

OEM connectors are key parts that make cars work better and last longer.

Good connectors make cars safer and more efficient. Companies like Eigen use smart technology to keep quality high. They follow rules to make sure car parts are strong and reliable. Picking the best connectors not only makes cars perform better but also makes people trust their car's safety.

See Also

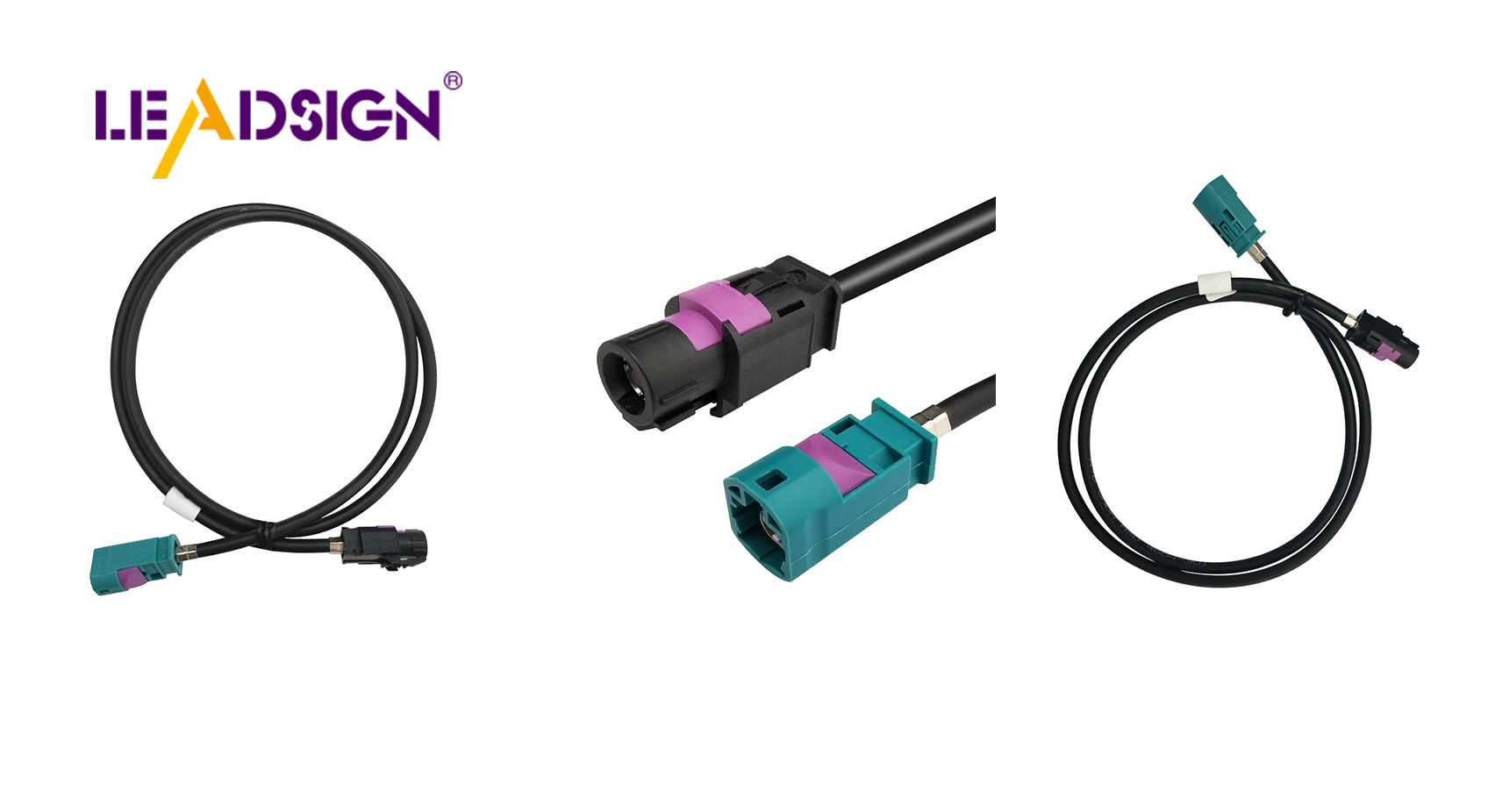

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors