Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in modern vehicles. They facilitate the seamless transfer of power and signals between components, ensuring optimal functionality. A typical car may contain around 40 harnesses, 700 connectors, and over 3,000 wires, highlighting the complexity of these systems. Each type of automotive electrical connector is designed for a specific purpose, providing robust connections and rapid data transmission. This is essential for both conventional and autonomous vehicles.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in cars. They link electrical circuits, keeping electricity flowing well. These connectors come in many shapes and sizes for different car needs. From big machines to small lights, wiring connectors help a car's electric system work.

Why are they crucial in automotive systems?

Car wiring connectors matter for many reasons. They make sure circuits connect safely, helping the car run smoothly. These connectors stop problems that can mess up how a car works. They ensure power and signals move easily between parts. This is important for things like engine control and lights. Knowing about different connectors helps with fixing or building cars.

Basic Components of Connectors

Contacts

Contacts are the main part of any connector. They let electricity pass between wires. Good contacts mean less resistance and better flow, which is important for good performance. In cars, contacts must handle heat changes and shaking.

Insulation

Insulation covers the contacts, stopping shorts and outside damage. It keeps conductive parts apart and protects from water or dirt. Different materials are used based on what they need to do, like handling high heat or chemicals.

Housing

The housing holds the contacts and insulation together, giving support and protection. It keeps the connector strong under pressure. Housing designs change for different uses, from small spaces to tough jobs. The housing often has locks to keep connections secure.

Automotive Electrical Connectors Types

Car connectors come in many types. Car connectors come in many types. Each type has a special job in cars. Knowing these helps pick the right one for the task, making sure it works well.

Blade Connectors

Features and Applications

Blade connectors are common in cars. They connect wires easily. They have a flat metal piece that fits into a slot. This makes them quick to use and secure, perfect for car radios and lights. Blade connectors are great when you need to unplug often.

Common Variants

There are different blade connectors like insulated and non-insulated ones. Insulated ones keep wires safe from shorts and weather. Non-insulated ones are used where safety is not a big worry. Both types come in sizes for different wire thicknesses.

Pin Connectors

Features and Applications

Pin connectors, or pigtail connectors, handle high power jobs. They have a pin fitting into a socket, making strong connections for big power needs like headlights or starters. These keep connections steady even when things get rough.

Common Variants

Pin connectors come as single-pin or multi-pin types. Single-pins are simple; multi-pins handle more wires at once. They often lock to stay connected, which is important in cars.

Ring and Spade Connectors

Features and Applications

Ring and spade connectors join wires to posts tightly. Rings wrap around posts firmly against shaking or moving parts. Spades slide on easily without removing screws fully. They're used with batteries or grounding where solid links matter.

Common Variants

Ring and spade connectors vary in size and material for different uses. Some have covers for safety; others withstand heat well. Picking depends on what they need to do, like how much power they carry or the conditions they face.

Rules and Guidelines

Industry rules

Industry rules make sure car wiring connectors are safe and work well. These rules keep things the same for all cars and makers. ISO and SAE rules

ISO Rules

The International Organization for Standardization (ISO) makes world rules for car connectors. ISO 12098 and ISO 7638 are important ones. ISO 12098 helps swap old connectors with new, better ones. ISO 7638-2 is about connectors for Anti-lock Braking Systems (ABS) and Electronic Braking Systems (EBS) in towing cars. It talks about a 12 Volt 7-pin trailer connector, which is key for safe links.

SAE Rules

The Society of Automotive Engineers (SAE) also makes rules for car connectors. These rules make sure connectors can handle tough car conditions like heat changes and shaking. SAE rules help makers build strong links between electric parts, which is crucial for car safety.

Maker Guidelines

Makers often have their own guidelines for car connectors. These guidelines make sure connectors fit their cars' special needs.

OEM Needs

Original Equipment Manufacturers (OEMs) set special needs for connectors in their cars. These needs ensure strong links inside car systems. OEM connectors must give safe connections to fixed machines and other car parts. They meet different car system needs, ensuring top performance.

Aftermarket Thoughts

Aftermarket connectors are choices besides OEM ones. When picking them, check if they fit current systems well. Aftermarket ones should move power smoothly like OEMs do. They must follow industry rules to keep the car working well.

Picking the Right Connector

Choosing the right car wiring connector is very important. It helps keep a car's electric system working well. This part will show you what to think about and mistakes to avoid when picking connectors.

Things to Think About

Electrical Needs

Car connectors link different electric parts in a car. They must meet certain needs to keep the car safe and working well. When picking a connector, think about these:

Current and Voltage Ratings: Make sure the connector can handle its power load. Too much power can cause it to overheat and break.

Signal Integrity: Pick connectors that reduce signal loss, especially where exact data is needed.

Environmental Conditions

Where a connector works affects how long it lasts. Think about these conditions:

Temperature Extremes: Will it face hot or cold temperatures? Choose ones made for such weather.

Moisture and Contaminants: Use waterproof connectors to protect against water, brake fluids, and other harmful things.

Vibrations and Mechanical Stress: Pick connectors that can handle shaking and stress for steady work.

Mistakes Not to Make

Forgetting Compatibility

Compatibility matters when adding connectors to a car's system. Avoid these errors:

Mismatched Connectors: Ensure they fit with current systems. Bad matches can cause weak links or failures.

Ignoring Manufacturer Specifications: Follow OEM rules for proper fit and function.

Overlooking Quality and Durability

Good quality connectors are key for lasting performance. Avoid these issues:

Choosing Low-Quality Materials: Bad materials wear out fast. Choose strong ones that resist bad weather.

Neglecting Durability Features: Look for features like self-cleaning contacts or seals for better reliability.

By thinking about these points and avoiding mistakes, you can pick the right connectors for your car's electric systems' best performance and safety.

Knowing about car wiring connectors is important for keeping a car's electrical system working well. These connectors make sure connections are safe, stopping problems like shorts or fires. When picking connectors, it's important to follow industry rules and guidelines. Good quality connectors last longer and work better, say the experts. They help keep cars safe and running smoothly. Choosing the right connectors protects the car and keeps it working its best. Focusing on quality and fit makes a car's system run well and stay in good shape.

See Also

Exploring HSD Connectors in Automotive Technology

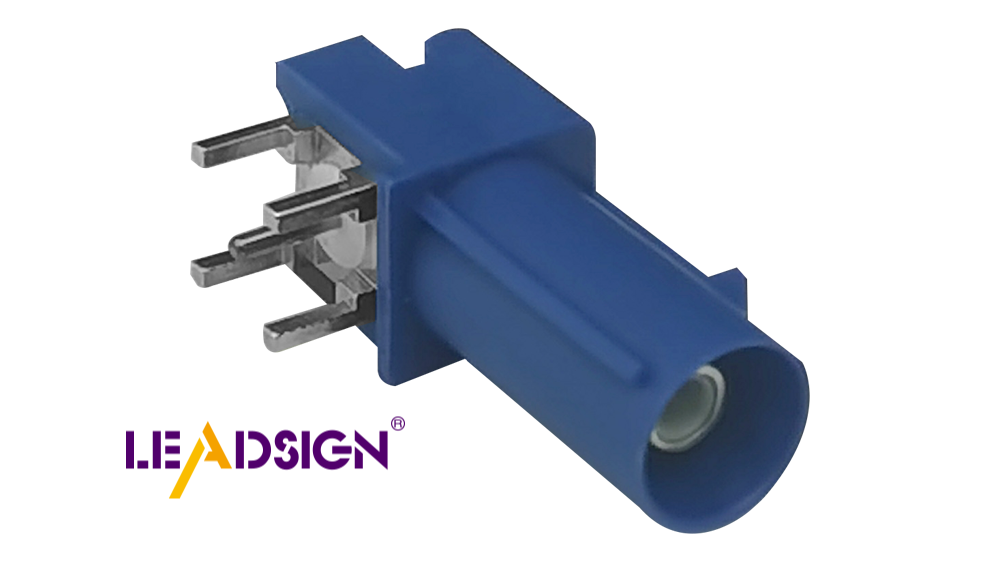

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connections