Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components in modern vehicles. They play a vital role in ensuring the proper and safe functioning of electrical systems. A typical car contains approximately 274 connectors, each facilitating communication between circuits. These connectors consist of various parts such as contacts, shells, insulators, and additional components. Unlike airplane wiring, car connectors are more prone to failure, underscoring their significance in automotive systems. Understanding the various types of automotive electrical connectors is essential for maintaining the optimal operation of a vehicle's electrical system.

Basics of Car Wiring Connectors

What are Wiring Connectors?

Definition and Purpose

Wiring connectors are key parts in car systems. They connect separate circuits, letting electricity flow easily. This makes sure the car's electrical parts work right. Car connectors usually have four main parts: contacts, shells, insulators, and extras. These parts help circuits talk to each other, making the car run well.

Importance in Car Systems

In today's cars, wiring connectors are very important. They make sure connections work well in complex systems with computers. As cars get more high-tech, good connectors are needed more. These must handle tough conditions while working well. Their dependability affects how the car works overall, making them vital in car design.

Common Materials Used

Metal Connectors

Metal connectors are picked for tough jobs. They conduct electricity well and resist rusting, so they're good for hard places. Metals like brass and bronze are used for these connectors because they last long and stay strong.

Plastic Connectors

Plastic connectors are light but strong too. They're used a lot in cars because they can do many things. The plastic often includes PA66 or PBT for insulation. These materials keep electricity from leaking out and help the connector work well in different situations. Plastic ones fit into small spaces in cars easily.

Types of Automotive Electrical Connectors

Knowing about different automotive electrical connectors is important. Each type has a special use and features that fit certain jobs.

Blade Connectors

Features and Uses

Blade connectors, also called spade terminals, are flat and slide into slots. They are popular in cars because they are easy to use. These connectors work well when you need to unplug and plug back often, like in fuse boxes.

Good and Bad Points

Good Points:

Simple to connect or disconnect; very user-friendly.

Stay connected even if the car shakes, which is important.

Bad Points:

Not great for high power because they have small contact areas.

Can get loose if not tightened well.

Pin Connectors

Features and Uses

Pin connectors, or pin terminals, have a round pin fitting into sockets. They are used in cars for sensors and controls. Their design saves space, making them good for tight spots.

Good and Bad Points

Good Points:

Small size helps save room in crowded wires.

Reliable connection for medium power loads.

Bad Points:

Hard to unplug without the right tools.

Need exact alignment to connect properly.

Butt Connectors

Features and Uses

Butt connectors join two wires straight together. They are used for fixing or adding wires in cars. These help extend wire length or fix broken ones.

Good and Bad Points

Good Points:

Easy design makes quick fixes simple.

Strong connection when crimped right.

Bad Points:

Not good if you need to unplug often.

Need crimping tools that might not be handy everywhere.

Knowing these automotive electrical connectors types helps pick the right one for each job, ensuring safe connections in cars.

Ring Connectors

Features and Uses

Ring connectors, or ring terminals, are important in car systems. They have a round end that fits over a bolt or screw to make a strong connection. These are used when you need a permanent link, like for grounding wires or battery ends. Their design makes sure the connection stays strong, which is key for keeping car electrical systems working well.

Ring connectors come in different sizes for various wire thicknesses and bolt sizes. This makes them useful for many car jobs. They are tough enough to handle shaking and rough conditions found in cars.

Good and Bad Points

Good Points:

Strong Link: The round shape gives a firm hold, so they don't come loose from shaking.

Flexible Use: Different sizes fit many wires and bolts, making them good for different car uses.

Long-lasting: Made of copper or brass, they conduct electricity well and don't rust easily.

Bad Points:

Hard to Remove: Once on, you need tools to take them off, so they're not great if you need to disconnect often.

Takes Time to Install: You must tighten with a bolt or screw, which can be slower than other types like blade connectors.

Knowing about ring connectors helps pick the right type for each car job. By weighing the good and bad points, you can keep car systems running smoothly. Understanding these connector types is key for safe and efficient cars.

Picking the Right Connector

Choosing the right connector is key to keeping a car's electrical system Choosing the right connector. Different automotive electrical connectors have different jobs, so picking the right one means thinking about a few things.

Things to Think About

Electrical Needs

First, check what electricity the connector needs to handle. This means knowing how much power and voltage it will carry. For example, ring terminals are great for strong connections like grounding wires or battery ends. Their round shape helps them hold tight.

Weather Conditions

Where the connector will be used matters too. It should handle tough conditions like heat, cold, wetness, and dirt. Insulated ring terminals protect against bad weather and stop rusting, keeping them working well in hot or cold places.

Mistakes to Avoid

Wrong Size

A common mistake is picking connectors that don't fit the wire size or job needs. If it's too big or small, it won't connect well and might fail. Make sure the connector fits the wire size for a good fit.

Bad Material Choice

Another mistake is choosing wrong materials for connectors. The material should match what you need it for. Metal ones like copper are great for carrying lots of electricity, while plastic ones work for lighter jobs. Picking wrong can make them not last long.

By knowing these tips and avoiding mistakes, people can choose the best automotive electrical connectors types. This keeps car systems safe and working well.

Installation Tips

Making Sure Connections Are Safe

To keep connections safe, focus on good quality. Safe links stop electrical problems and make sure everything works well. Always check connectors fit tightly and aren't rusty or broken. Aligning them right is key; wrong alignment can cause bad contact and issues. Check often to keep connections strong, especially in tough weather.

Tools You Need

Right tools make installing easier. Important ones are wire cutters, crimpers, and testers. Wire cutters take off covers without hurting wires. Crimpers make wires and connectors fit tight for a strong link. Testers check if the connection works by measuring power flow. Using these tools right helps the car's electric system last longer.

Common Questions

How to Know Connector Types?

To know connector types, look at their shape, size, and what they're made of. Blade connectors are flat; pin ones have round pins. Think about what they're used for, like high or low power jobs. The car's guidebook or an expert can help find the right type.

What If Connectors Break?

If connectors break, act fast to stop more harm. First, look for signs of wear or damage on them. Change broken ones with new ones that match the car's needs. Make sure new parts are put in right using proper tools. Regular checks can catch problems early to avoid future breaks.

Choosing the right car wiring connectors is very important. They help keep a car working well and safely. Good connectors make sure fixes last a long time, which helps the car run better.

"Using good connectors makes repairs last longer," says an expert.

To get better wiring in cars, use smart tips like making sure connections are tight and using the right tools. By knowing and using these ideas, people can keep their car's electrical parts working well.

See Also

Exploring HSD Connectors in the Auto Sector

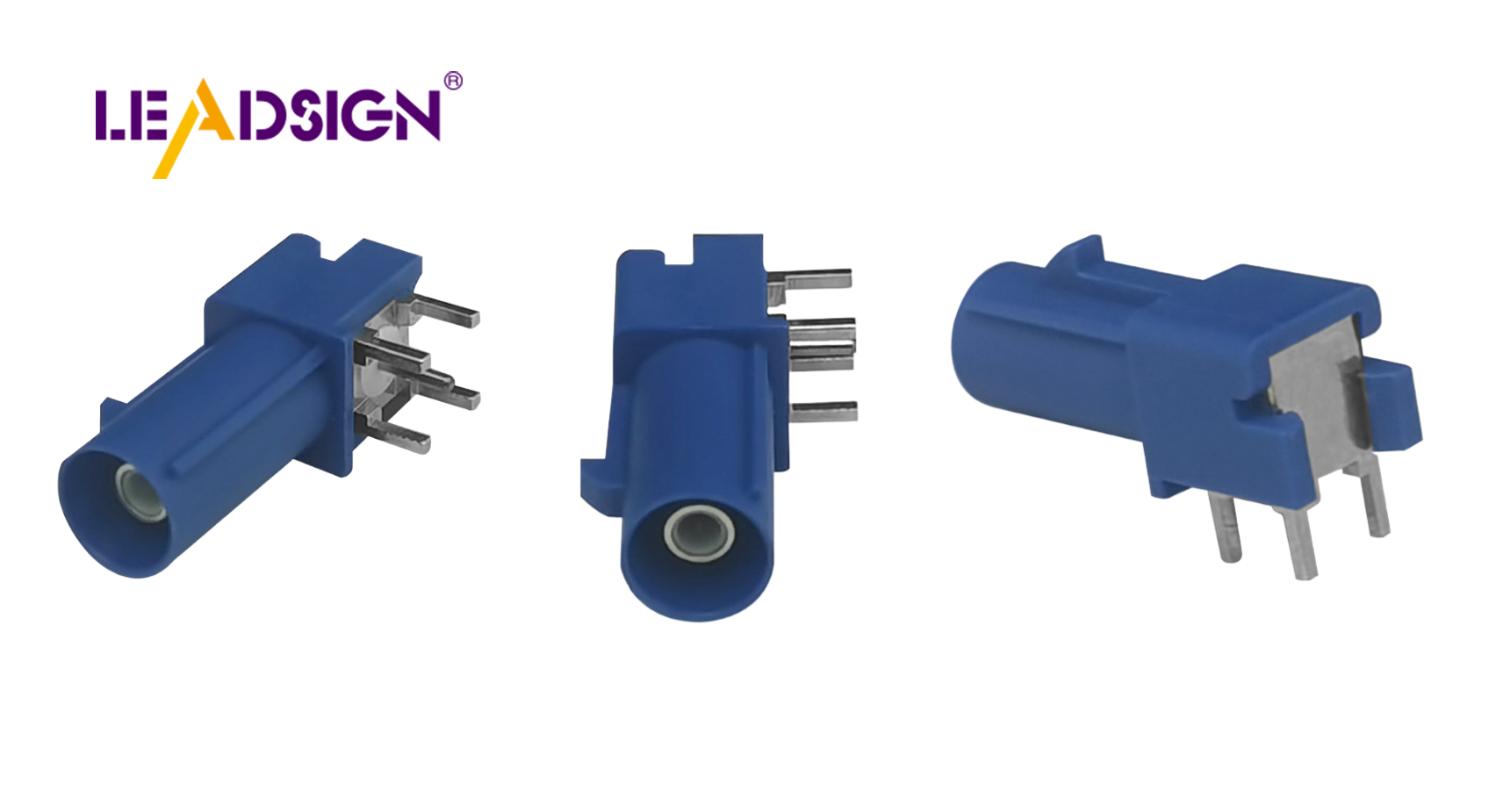

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System