Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial in modern vehicles, ensuring efficient electricity flow that supports the seamless operation of various systems. These connectors facilitate the transmission of power and signals, essential for the functionality of GPS and safety systems. As technology advances, the demand for diverse automotive electrical connectors types increases. The market for these connectors is projected to expand from US$6.71 billion in 2023 to US$8.38 billion by 2028, highlighting their significance in enhancing vehicle safety and performance.

Overview of Car Electrical Connectors Types

Car electrical connectors are key parts in vehicles. They help all electric systems work well. These connectors keep wires connected and working right in cars.

Basic Functions and Importance

Keeping Electricity Flowing

Car connectors let electricity move without stopping. They link wires and parts, so power flows smoothly in the car. This is important for lights, engine control, and music systems. Without good connectors, these might not work, causing safety problems.

Protecting from Weather

Connectors need to handle tough weather. They block water, dirt, and temperature changes. This keeps electric systems working in all places. Good connectors stop rust and damage that can hurt electric flow over time.

Common Materials Used

The materials used for car connectors affect how they work and last. Designers pick materials that can survive car conditions.

Metal Alloys

Metal alloys are often used because they conduct electricity well and are strong. They make a strong link that handles lots of power and lasts long. These metals are coated to stop rust, making them reliable over time.

Plastic and Composite Materials

Plastic materials make light and bendy connectors. They cover wires safely and are easy to use. BASF's Ultramid is a plastic that makes strong plug connectors. These materials help cars weigh less and save fuel.

Car electrical connectors change as technology grows. They help connect new systems like smart driving aids, electric cars, and entertainment techs in cars. As cars get better, we will need even better connectors change as technology grows too.

Types of Car Electrical Connectors

Car electrical connectors are important for vehicle systems to work well. Different connectors have different jobs and features. Knowing these helps pick the right one for each car need.

Blade Connectors

Blade connectors, or spade connectors, are flat and thin. They fit into a slot, making them easy to connect and disconnect.

Features and Uses

Blade connectors have a flat metal piece that slides into a slot. This makes connections quick and secure. They are used in cars for connecting wires to switches, relays, and fuses. Their simple design is good when you need to disconnect often.

Good Points and Limits

Blade connectors are reliable and easy to use. They install quickly, which helps in car repairs. But they might not be best where there's lots of shaking because they can loosen over time. Also, they may not block water or dirt well.

Pin Connectors

Pin connectors, called male connectors too, have pins that fit into female parts.

Features and Uses

Pin connectors have round pins that go into matching holes. They're used in cars for sensors and control units. Their design keeps connections safe and steady for important systems.

Good Points and Limits

Pin connectors make strong connections that don't come apart easily by accident. They're great where a steady link is needed but can be harder to set up than blade ones. They might also need extra sealing against weather.

Ring and Spade Connectors

Ring and spade connectors join wires to posts or screws.

Features and Uses

Ring ends fit over bolts; spade ends look like forks. These connect wires in cars for batteries or grounding where a tight hold is needed on posts or terminals.

Good Points and Limits

Ring and spade give strong holds but need tools to put on or take off, which isn't fast if you need quick changes. They might not protect as well from weather as other types do.

Knowing about different car connector types helps choose the best one for each job since each has its own features, good points, and limits.

Automotive connectors must follow rules for safety. These rules help make sure connectors work well in cars.

ISO and SAE Rules

ISO and SAE set the rules for car connectors. These rules make sure connectors work in different conditions.

Important Details

ISO and SAE tell what materials and sizes are needed. They say how strong connectors should be. This helps them handle tough car conditions like heat and shaking.

Testing and Following Rules

Makers test connectors to check if they follow ISO and SAE rules. Tests see if connections stay strong under pressure. This makes sure they work well, keeping cars safe.

Connector Ratings

Connectors have ratings showing where they can be used. These help pick the right one for each job.

Power Ratings

Each connector has a power limit it can handle safely. Picking the right one stops overheating or breaking in car systems.

Weather Ratings

Weather ratings show how well a connector handles water, dust, or heat. Good ratings mean they protect car electronics from harm.

In short, knowing these rules is key for safe connectors. They ensure that connectors fit their jobs well, boosting car safety.

As technology gets better, connectors will be key in making car electronics smarter and safer. Knowing about these connectors helps people make smart choices to keep cars running well for a long time.

See Also

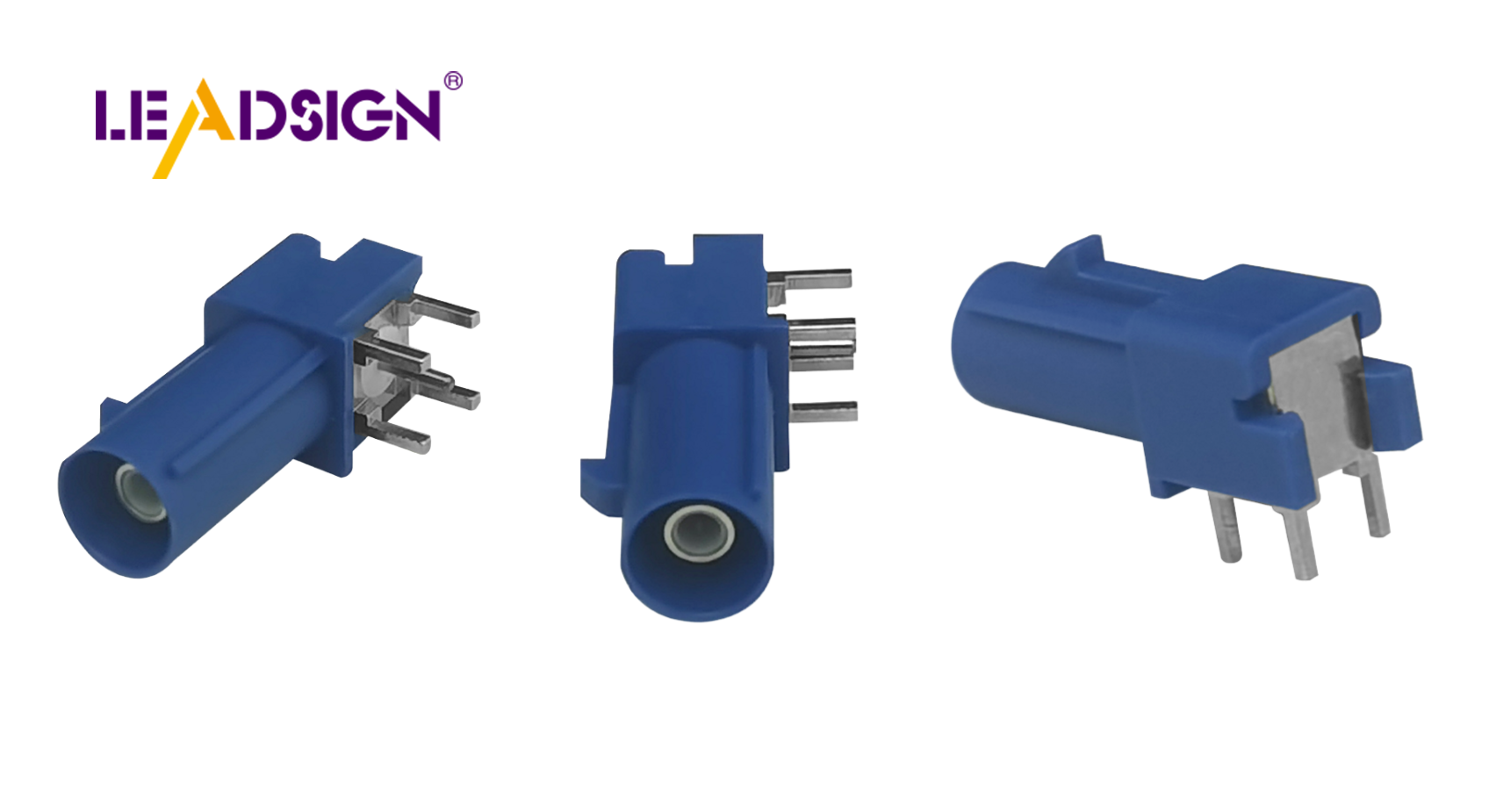

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System