Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in today's vehicles. They facilitate communication and power distribution between components, such as the engine and radio. As cars become more sophisticated, the demand for advanced connectors increases. Connectors, including wire-to-wire types, ensure optimal vehicle performance. In 2022, the market for these connectors reached USD 7.9 billion, highlighting their significance. They transmit electrical signals to ensure smooth driving, making them essential in automobiles.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car electrical systems. They link wires to make circuits, helping signals move smoothly in the car. These connectors have many shapes and sizes for different needs. By joining circuits, they help signals travel well, making the car work better.

Why are they essential in automotive systems?

Car wiring connectors help parts talk to each other. They boost how a car works and keeps it safe by linking things like the engine and radio. As cars get more advanced, we need better connectors. This makes them very important today. They send signals well so cars run smoothly.

General Characteristics

Material Composition

The materials used for car wiring connectors matter a lot. Makers use copper or brass because they conduct electricity well and don’t rust easily. These materials help connectors last long in tough conditions. The material choice also affects how much power they can handle.

Design and Structure

Connectors are designed for specific uses in cars. They have male (plug) and female (socket) parts that fit together tightly. The design must match different pin sizes and circuit needs to work with various systems. As technology grows, connectors get more features to meet new demands while staying safe.

Car Electrical Connector Types

Car electrical connectors are important for cars to work well. Each type has a special job, helping parts connect safely. car electrical connectors

Blade Connectors

Features and Uses

Blade connectors, also called spade connectors, have a flat male piece. It fits into a female spade part. This makes connecting easy and safe. They are popular because they can be used many times without breaking. You don't need solder to use them, which is why many people like them for cars.

Common Applications

Blade connectors are used where car parts need fixing or changing often. They help connect wires to blocks easily and safely. You can attach wires without taking out screws all the way, which is handy when you need quick access.

Pin Connectors

Features and Uses

Pin connectors make connections strong and reliable. They have a round pin that fits into a socket tightly. These are good for places with lots of shaking or movement in cars.

Common Applications

Pin connectors are used where there’s lots of movement in the car. They connect sensors and other parts that need to stay connected well. Their strong design keeps them working even when things get bumpy.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end securely. They’re used when you want a permanent connection. The design keeps wires from coming apart by accident.

Common Applications

Butt connectors are used in car wiring harnesses to fix or extend wires. They join wires without needing soldering, making them great for mechanics or DIY projects at home. Their secure hold helps keep car systems working right.

Ring and Spade Connectors

Features and Uses

Ring and spade connectors are important in car electrical systems. They connect wires without soldering, making them easy to use. Ring connectors have a round end that fits over bolts or screws for a strong hold. This makes them great for grounding where stability is needed. Spade connectors have a fork shape that lets you attach to terminal blocks easily without taking out screws completely. This makes them good for quick connections.

Both types are made from strong materials like copper or brass. These metals conduct electricity well and don't rust easily, so they last long in tough car conditions. Their design also makes them simple to put on and take off, which is why mechanics and DIY fans like them.

Common Applications

Ring and spade connectors are used a lot in cars because they work well and are reliable. Ring connectors are often used for grounding, giving a stable link to the car's body. This helps keep the electrical systems working right by preventing loose connections.

Spade connectors are used when quick wire connections are needed. They help connect wires to terminal blocks fast, making repairs easier. They're especially useful where parts need regular access or changes, like fuse boxes or relay panels.

Choosing Wiring Connectors

Picking the right car connectors needs knowing some important things. These help connectors work well in different situations.

Environmental Factors

Temperature Handling

Cars face very hot and cold temperatures. Connectors must handle these to keep working. Good connectors don't melt or break in heat or cold. This is key for keeping connections steady all year round.

Water and Rust Protection

Water and rust can harm connectors a lot. Car connectors often have special coatings to stop rust. This keeps them working even when it's wet, stopping electrical problems.

Electrical Needs

Power Limits

Each connector has power limits it can safely handle. Knowing these stops overheating and damage to car systems. For example, spade connectors come in sizes for different wires and power levels.

Fit with Wires

Connectors must fit with car wires for good power flow. Spade connectors are flexible, fitting screws or quick connects easily. This makes them great for many uses like radios or batteries.

By thinking about these points, people can pick the best car connectors for their needs. This helps cars run better and more reliably.

Practical Tips for Using Wiring Connectors

Installation Best Practices

Tools Needed

To install car wiring connectors, you need special tools. Important tools are:

Wire Strippers: These take off the plastic cover from wires without hurting them.

Crimping Tool: This tool attaches connectors to wires tightly and safely.

Multimeter: It checks if electricity flows well through the connection.

Heat Gun: Used to shrink tubing for extra protection on connections.

Step-by-Step Guide

Prepare the Wires: Strip half an inch of cover from wire ends.

Pick the Right Connector: Choose one that fits your wire size and needs.

Crimp the Connector: Put wire in connector, then crimp it tight with a tool.

Test the Connection: Use a multimeter to make sure it's working right.

Cover the Connection: Slide shrink tubing over it, then heat it for safety.

Maintenance and Troubleshooting

Regular Check Tips

Checking wiring connectors often helps them last longer. Here’s how:

Look Over Them: See if there’s damage or rust on connectors. Rust means water got in.

Check Tightness: Make sure all connections stay tight to avoid problems.

Clean Them Up: Use cleaner to get rid of dirt on connectors for good flow.

Common Problems and Fixes

Rusty Parts: Water can cause rust, making bad connections. Grease can help keep water away.

Too Hot Connections: This happens if too much power goes through a small connector. Use ones that handle more power to stop this.

Loose Parts: Loose parts can cause problems with electricity flow. Crimp again or change loose connectors.

By following these tips, people can keep their car electrical connectors working well, which helps cars run safely and smoothly.

Choosing the right car wiring connector is very important. The right connector helps parts talk and share power well. When picking connectors, think about what you need and how they work. Things like what they're made of, how they handle weather, and if they fit with your car's wires are key.

"Strong connectors that don't mess up are vital, especially without expert help," says an expert.

Picking good connectors makes cars work better and cuts down on fixes, making driving easier and safer.

See Also

Exploring HSD Connectors in the Automotive Sector

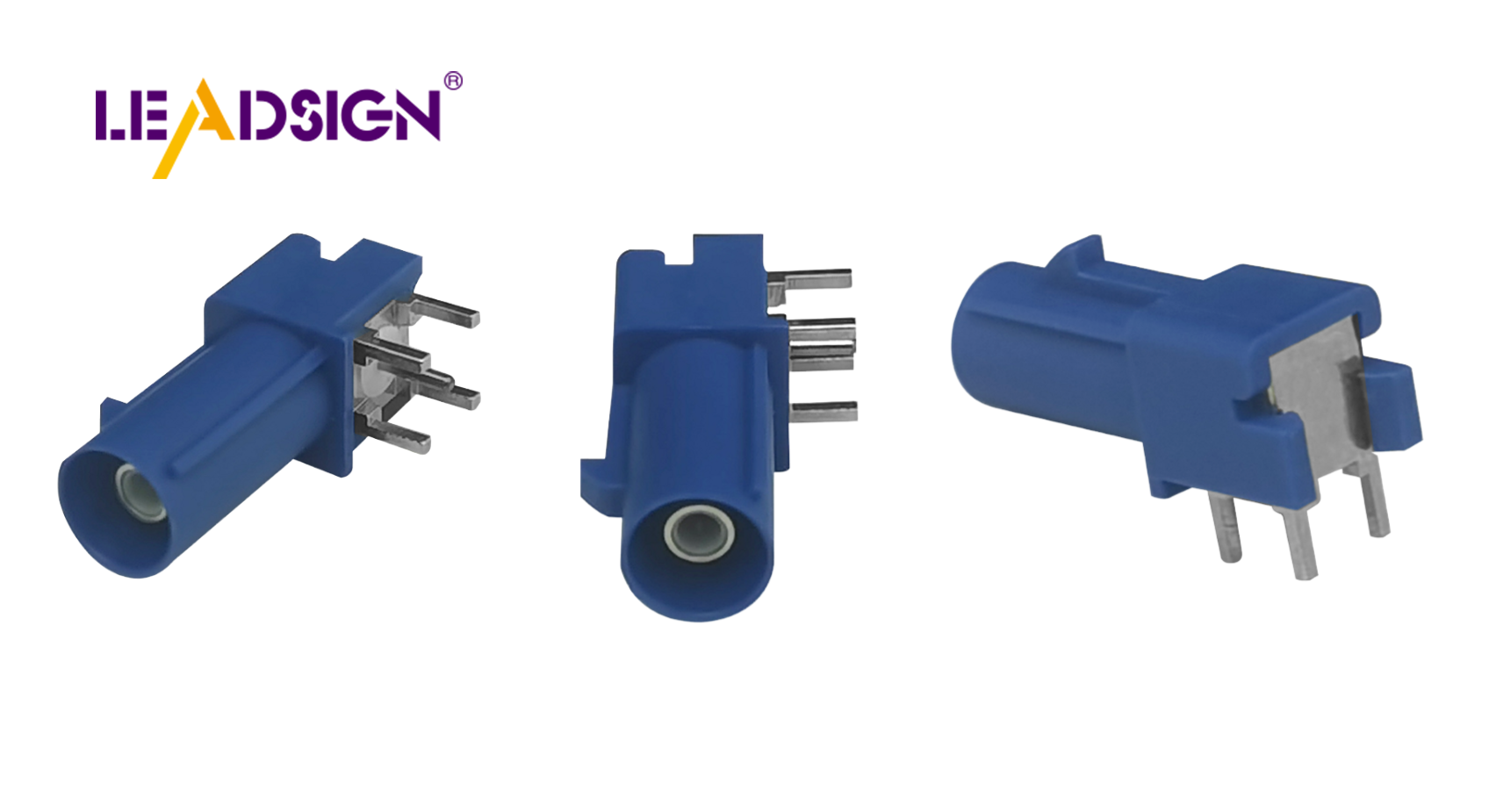

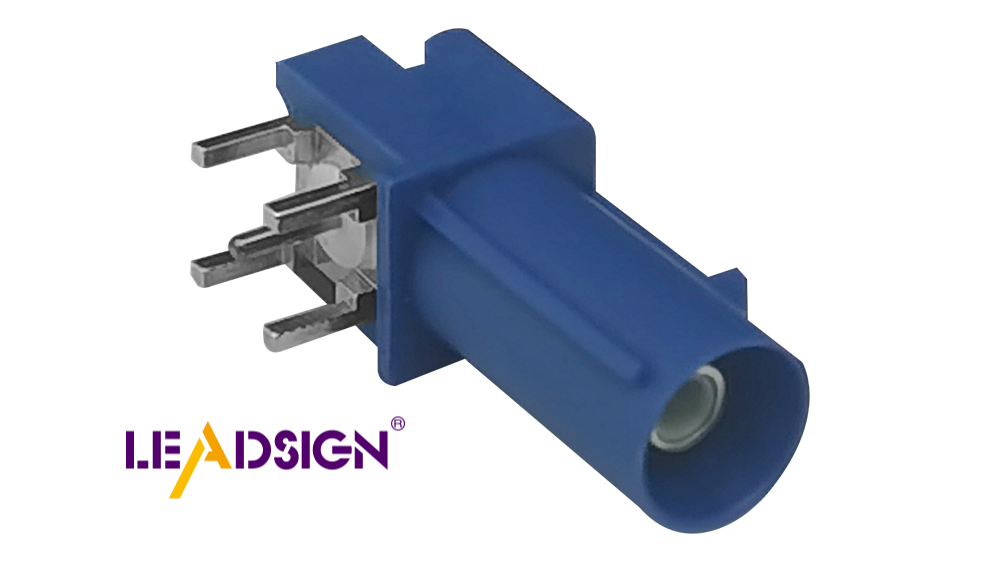

Significance of FAKRA Connectors in Contemporary Cars

Navigating Ford FAKRA Connectors