Understanding Automotive Wiring Connector Types

Automotive electrical connectors play a crucial role in modern vehicles. They ensure the proper and safe functioning of the car's electrical components. In 2022, the market value of these connectors reached USD 7.9 billion, highlighting their increasing significance. With the rising demand for electric cars, efficient electrical systems are essential. There are various automotive electrical connectors types designed for specific purposes and applications. Understanding these types is key to selecting the most suitable connector for optimal performance and safety.

Types of Car Electrical Connectors

Knowing about car electrical connectors is important. It helps keep a car's electrical system safe and working well. Each connector type has its own job and benefits. Let’s look at some common ones used in cars.

Blade Connectors

Blade connectors are very popular in cars. They have a flat or funnel shape, making them easy to plug in and out.

Features and Uses

These connectors are made from strong copper that lasts long. Their shape stops wires from bending too much, keeping connections safe. They come in many shapes and sizes for different uses.

Where Used in Cars

In cars, blade connectors join wires to things like lights and horns. They are easy to use, so both makers and fixers like them.

Pin Connectors

Pin connectors are also important in cars. They connect wires well, letting electricity flow smoothly.

Features and Uses

Pin connectors handle high power levels safely. They often lock in place so they don’t unplug by accident, which makes them safer.

Where Used in Cars

These are used where strong connections are needed, like engine parts or sensors. Their tough build works well even when the car shakes a lot.

Butt Connectors

Butt connectors join two wires together easily.

Features and Uses

They’re made from materials that don’t rust or wear out fast. Butt connectors make sure electricity flows without stopping between wires.

Where Used in Cars

In cars, butt connectors are found where wires need joining securely, like wiring harnesses. They're simple to fit even when space is tight.

Knowing these connector types helps pick the right one for each job. Each type has special strengths that help a car’s electrical system work safely and well.

Features and Specifications

Knowing about connector features is important. It helps cars work well and stay safe. Connectors need to meet certain rules to work in different places.

Material Composition

The stuff used to make connectors matters a lot. It affects how they work and last. Makers like copper and aluminum because they are strong and good for electricity.

Conductivity and Durability

Connectors need to let power flow easily. Copper is great for this because it’s very conductive. It helps electricity move with less waste. Also, connectors must be tough. They should handle daily use without breaking down, keeping connections strong.

Resistance to Environmental Factors

Car connectors face things like water, heat changes, and rust makers. To fight these, they have special coatings and seals. These keep them from rusting and help them work in bad conditions. As more electric cars come out, the need for tough connectors grows.

Size and Compatibility

Connector size matters a lot too. They must fit right into the car's system to work well.

Standard Sizes

Using standard sizes makes making connectors easier. It also means they can fit many car types easily, which helps with fixing them fast.

Compatibility with Vehicle Models

Connectors must fit different cars well. Makers design them so they match each car’s needs perfectly, helping the car run safely.

Industry Rules and Guidelines

Knowing industry rules is key for safe car connectors. These rules help makers create good quality connectors.

ISO Rules

The International Organization for Standardization (ISO) makes global rules. These ensure products are safe and work well.

Role in Making

ISO rules are important in making things. They help makers meet world quality levels. For instance, ISO 12098 is for new car connectors, replacing old ones like ISO 1185. This change makes sure connectors fit new car tech and safety needs.

Following the Rules

Makers must follow ISO rules to sell worldwide. This means testing to check if connectors meet standards. Doing this makes products reliable and builds trust in car electrical safety.

SAE Rules

The Society of Automotive Engineers (SAE) sets car industry rules. These cover many parts of making cars, including connectors.

Role in Making

SAE rules keep car making consistent and high-quality. They give steps to make strong connectors that work in different conditions.

Following the Rules

Following SAE rules is vital for good connector making. They need tests to see if connectors can handle tough conditions. Meeting these rules ensures quality and meets safety goals.

In short, following ISO and SAE helps make good car wiring parts. These guides help create safe, reliable products that keep cars running smoothly.

Understanding car wiring connectors is important for keeping cars safe and working well. Each type, like blade, pin, or butt connectors, has a special job and benefits. Picking the right one means thinking about what it's used for and new car tech needs, like smart driving help and entertainment systems.

"New tech in connecting and talking is making more car connectors needed."

When picking connectors, following rules like ISO and SAE is key. These rules make sure they work well together and are reliable as cars need faster data connections more often.

See Also

Exploring HSD Connectors in the Auto Sector

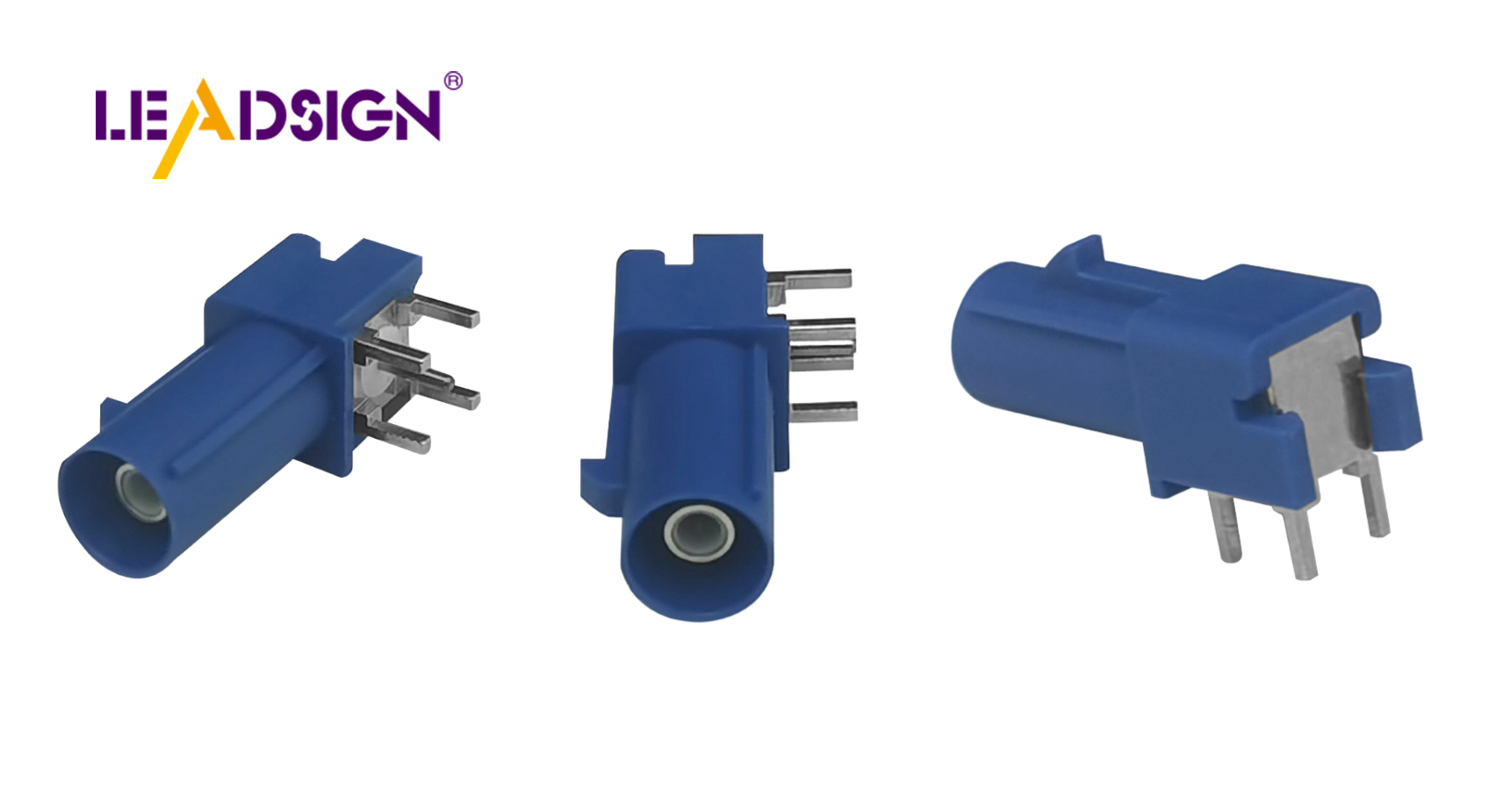

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System