Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles, ensuring that electrical systems function efficiently and safely. These connectors guarantee secure connections, which are essential for the proper operation of automotive components. There are various types, such as crimp and solder connectors, designed for specific applications. The quality of these connectors depends on factors like pin count, environmental conditions, and frequency of use. Understanding these aspects helps in selecting the appropriate connector for each task, ensuring the safety and longevity of automotive systems.

Basics of Car Wiring Connectors

Main Parts

Car wiring connectors have important parts to work well.

Connector Cover

The connector cover is the outside part. It keeps inside parts safe from dust, water, and damage. Makers use strong materials for these covers. They can handle heat and bad conditions, lasting a long time.

Metal Ends

Metal ends are inside the connector for electric links. They are usually copper or brass because they conduct electricity well. Their design keeps wires connected safely, lowering the chance of electric problems.

Protective Rings

Protective rings keep dirt and water out of connectors. This stops rust or short circuits. These seals make connectors more reliable in tough car situations.

Connector Jobs

Car wiring connectors do key jobs for a car's electrical system.

Electric Link

Connectors mainly give a steady electric link between parts. This helps power move smoothly in the car. Some have self-cleaning contacts to remove rust and dirt for good connections.

Physical Support

Connectors also give physical support to wires. They handle shakes and pulls when cars move. This strength stops wires from coming loose and keeps them working right.

Weather Shielding

Weather shielding is another big job of car connectors. They guard against heat, wetness, and harmful stuff. This protection helps them last longer and cuts down on electric issues in hard conditions.

Automotive electrical connectors are important for a car's electrical system. They come in different types for various uses. Knowing these helps pick the right one for each job, ensuring everything works well.

Crimp connectors are popular because they are simple and reliable. They work by squeezing a metal piece around the wire, making a strong link. This gives good strength and lets electricity flow easily. Crimp connectors are easy to put on and handle shaking well, which is great for cars.

Solder connectors make a lasting connection using solder to join wires. This makes them very strong and good at letting electricity pass through. They take more skill and time to attach but work better where there is lots of shaking.

Insulation displacement connectors (IDCs) connect quickly without taking off wire covering. They poke through the cover to touch the wire inside. IDCs are used when speed is needed and work well with low power.

Power connectors carry lots of electricity safely in cars. They keep power steady for important parts like engines and lights, even in tough conditions.

Signal connectors send small electric signals Signal connectors send small electric signals between car parts like sensors and controls. They need to keep signals clear without mixing them up.

Data connectors move information fast inside cars with fancy systems like GPS or music players. They must handle lots of data quickly while keeping it clear.

Features and Specifications

Material Considerations

Conductivity

Car wiring connectors need materials that carry electricity well. Copper and brass are often used because they move electric currents easily. These metals help car systems work smoothly, using less energy and working better. The metal choice affects how well the connector works.

Corrosion Resistance

Stopping rust is important for car connectors since they face tough conditions. Makers use nickel-plated brass or stainless steel to stop rust. These materials keep connectors from breaking down, making them last longer and work well. By stopping rust, connectors stay strong over time.

Design Features

Locking Mechanisms

Locking parts keep connections tight in cars. They stop wires from coming loose when cars shake or move. Connectors have main and extra locks for more safety. These locks make sure connections stay strong, lowering the chance of problems.

Polarization

Polarization makes sure connectors fit only one way. This stops wrong connections that can cause damage or issues. By using polarization, makers make car wiring safer and easier to install right.

Waterproofing

Waterproofing keeps water out of connectors near wet areas. Seals stop water from getting inside and damaging parts. Waterproof connectors are key in engines or outside lights, keeping links safe even when wet.

As per MIL-HDBK-217, using steady ways to check reliability is key. This guide stresses thinking about things like moisture when checking how long electronic parts last.

Industry Rules and Makers

Important Rules

ISO Rules

The International Organization for Standardization (ISO) makes global rules for car connectors. These rules make sure connectors are safe and work well. ISO looks at connector strength, how they handle wear, and weather effects. By following these rules, makers can create connectors that link many electric parts without problems.

SAE Rules

The Society of Automotive Engineers (SAE) also sets important rules for car connectors. SAE focuses on safety, staying strong, and working right. They make sure connectors survive tough car conditions and keep working over time. These rules help makers design connectors that fit the needs of today's cars.

Top Makers

TE Connectivity

TE Connectivity is a top maker in the car connector world. They have many types of connectors for different car uses. TE focuses on new ideas and good quality, making sure their products meet ISO and SAE rules. Their connectors are strong and trusted by many car makers.

Molex

Molex is another big name in the car connector field. They offer connectors for all kinds of car needs. Molex makes sure to follow industry rules so their connectors work safely and well. Their focus on quality has made them a reliable choice for car parts.

By sticking to ISO and SAE rules, companies like TE Connectivity and Molex ensure their connectors meet high standards in the auto world. This helps make sure connections are safe and last long, improving how cars work overall.

Picking the right car wiring connector is very important. It keeps the car safe and working well. The right connector helps the car's electric parts work better. As cars need more, choosing connectors that are safe and fit new tech is key.

New connector technology gives us high-density connectors. These keep signals clear and can be used in many ways. They help cars be ready for future changes, making them better. Knowing about these new connector technology helps choose wisely, keeping car systems strong and lasting long.

See Also

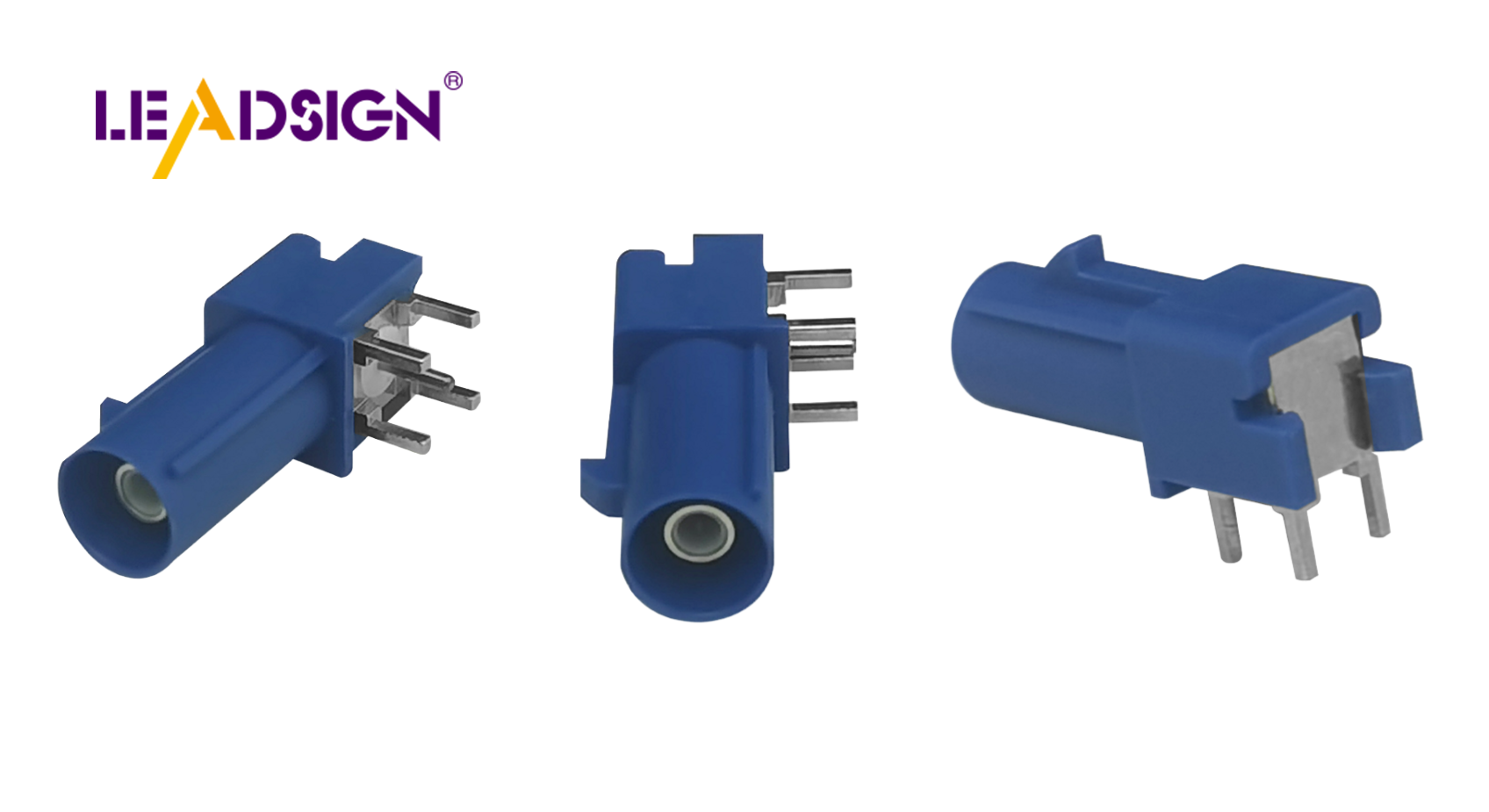

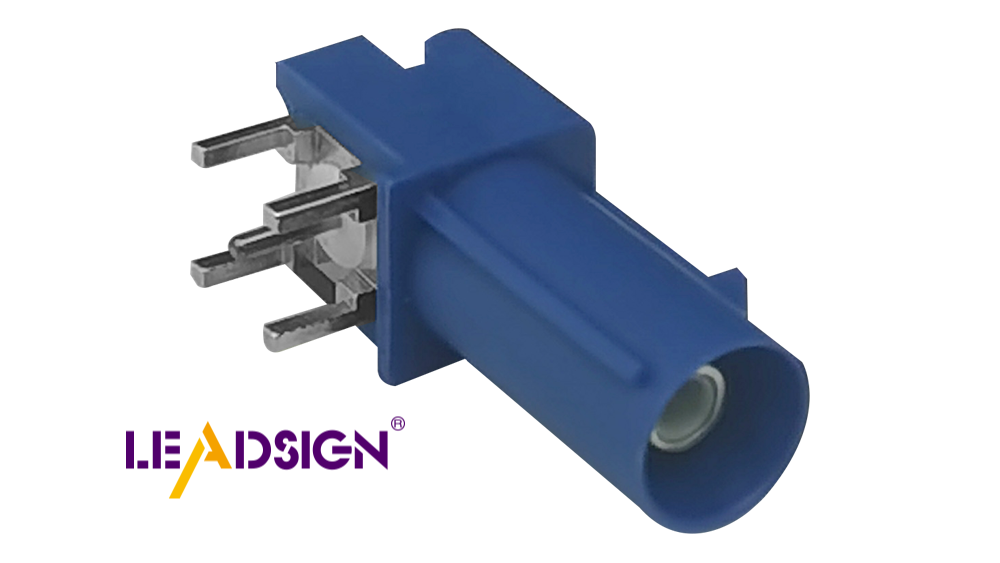

Exploring HSD Connectors in Automotive Technology

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System