Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for today's vehicles. They ensure that electrical connections function properly, which is essential for car safety and the correct operation of systems. These connectors prevent issues that may arise from improper handling or misuse. Connectors are more prone to failure compared to regular wires, underscoring the importance of selecting the appropriate types and maintaining them effectively. Understanding the various automotive electrical connector types is vital for ensuring the safe and seamless operation of vehicles, guaranteeing optimal functionality across all systems.

Exploring Automotive Electrical Connectors Types

Automotive electrical connectors types are very important for cars to work well. Knowing the different kinds helps automotive electrical connectors types, making cars safer and better.

Blade Connectors

Features and Applications

Blade connectors, also called spade connectors, are common in cars because they are simple and work well. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect, great for when you need to do it often.

Applications:

Used in car audio systems

Common in lighting circuits

Suitable for battery connections

Advantages and Disadvantages

Blade connectors have good points like being easy to use and fitting tightly. They stay connected even when the car shakes. But they might not be good for strong currents because of their small contact area.

Advantages:

Easy to connect and disconnect

Reliable in high-vibration environments

Disadvantages:

Limited current-carrying capacity

Potential for corrosion if not properly insulated

Pin Connectors

Features and Applications

Pin connectors are another favorite type of automotive electrical connectors types. They have a round pin that goes into a socket, making a strong connection. These are used where many connections fit in small spaces.

Applications:

Engine control units

Sensor connections

Infotainment systems

Advantages and Disadvantages

Pin connectors make strong links with little chance of coming apart by accident. They can fit different pin setups but need careful lining up when put together, which is hard in tight spots.

Advantages:

Secure and stable connections

Versatile pin configurations

Disadvantages:

Requires precise alignment

Can be difficult to disconnect in confined areas

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end so electricity flows through them. They're used often for fixing or changing car wiring. You crimp them onto wires for a tough link.

Applications:

Wire repairs

Modifications in wiring harnesses

Extending wire lengths

Advantages and Disadvantages

Butt connectors are easy to set up and give a solid connection but might not hold up if things shake unless secured well.

Advantages: Simple installation Reliable connection

Disadvantages: May require additional securing in high-vibration areas Limited to joining two wires only

Knowing these automotive electrical connector types is key for anyone working on cars. Each has special features, so picking the right one is important.

Ring and Spade Connectors

Ring and spade connectors are important parts of automotive electrical connectors types. They make strong connections, so they are used a lot in cars.

Features and Applications

Ring connectors have a round end that goes over bolts, making them very strong. Spade connectors have a forked end that fits under screws for easy use. These are used where solid connections are needed.

Applications:

Battery ends

Ground wires

Starter motors

Alternator links

These connectors work well in places with lots of shaking, like engines. Their shape keeps them attached even when things get rough.

Advantages and Disadvantages

Ring and spade connectors have many good points, which makes them popular among automotive electrical connectors types. They stay connected in heat and shaking, which is key for cars. But they do have some downsides.

Advantages:

Strong links

Easy to put on or take off

Good for shaky spots

Disadvantages:

Need tools to attach

Limited wire movement

These are best when you need a lasting connection. Their tough build keeps them working even in bad conditions, making them vital in car systems.

Things to Think About When Picking Connectors

Picking the right automotive electrical connectors types is key for a car's electric system to work well. You need to think about many things before choosing.

Electrical Needs

Knowing what electricity needs are is important when picking connectors. Different uses need certain current and voltage levels, which affect how well and safe the electric system works.

Current and Voltage Levels

Current Levels: Each connector can handle only so much current. Going over this can cause overheating or failure. For example, blade connectors might not be good for high currents because they have small contact areas.

Voltage Levels: Voltage levels show the highest voltage a connector can safely take. Picking connectors with the right voltage levels makes sure they can handle the electric load without breaking down.

Environmental Factors

The environment affects how well automotive electrical connectors types work. Things like temperature, wetness, and chemicals can change how long connectors last and how they work.

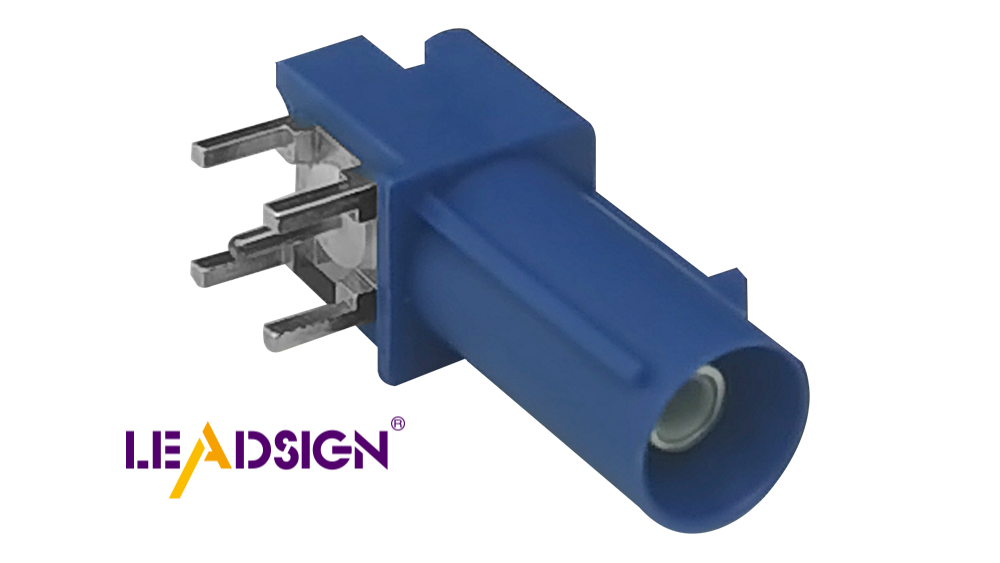

Temperature Range: Connectors should work well in the car's temperature range. For instance, FAKRA connectors work from -40 °C to +105 °C, making them good for many car uses.

Wetness and Chemical Safety: In places with lots of water or chemicals, picking waterproof or rust-proof connectors is important. This helps them last longer in tough conditions.

Mechanical Needs

Mechanical things like strength, material, size, and fit matter when picking automotive electrical connectors types.

Strength and Material

Material Choice: The connector's material affects its toughness and wear resistance. Good materials like those in crimp connectors give strong links when put on right.

Strength: Connectors must handle stress and shaking common in cars. Strong ones lower disconnection risks and keep working well.

Size and Fit

Size Thoughts: Connector size should match space in the car design. Small ones fit tight spots; big ones may be needed for strong links.

Fit with Systems: Making sure they fit with other parts is crucial. Connectors must fit easily with other parts to avoid setup problems and work smoothly.

Picking the right automotive electrical connectors types means looking at these points closely. By thinking about electric and mechanical needs, you can pick connectors that suit your project best for a reliable car electric system.

Real-World Uses and Setup Advice

Knowing how to use and set up automotive electrical connectors types helps cars work better. Doing it right keeps the connectors working well, stopping electric problems.

Mistakes When Setting Up

Avoiding mistakes is key when putting in automotive electrical connectors types. Errors can cause bad links and system troubles.

Stopping Bad Links

Make Sure Connections Are Tight: Loose links can cause power issues. Always check that connectors are tight.

Use Correct Tools: Wrong tools can break connectors. Hex or round tools fit better than deep indent ones.

Match Connector Types: Use connectors that fit the system's needs. They must handle the circuit's power and fit right.

Keeping Insulation Good

Pick Good Insulation Stuff: Quality insulation stops water and dirt from hurting connections, especially in tough places.

Look for Insulation Damage: Check often for wear or damage on insulation. Replace broken ones fast to keep things safe.

Care and Fixing Problems

Regular care and fixing help automotive electrical connectors types last long. Spotting problems early stops bigger issues later.

Finding Bad Connectors

Look Closely at Them: Check for rust, color change, or breaks often as these show bad connectors.

Do Electric Tests: Use testers to check flow and resistance; weird results mean a connector might need changing.

Tips for Fixing or Changing

Change Instead of Fixing: Usually, it's better to swap out bad ones than fix them for strong connections.

Follow Maker's Rules: Stick to maker's steps when swapping connectors to ensure they work best together.

By knowing these uses and setup tips, people can manage automotive electrical connectors types, keeping car systems reliable.

Frequently Asked Questions (FAQs)

How to Pick the Right Connector?

Choosing the right automotive electrical connectors types is key for cars to work well and safely. Here are some tips to help you choose:

Check Electrical Needs: Know how much current and voltage the connector needs to handle. This makes sure it won't overheat or break.

Think About Environment: Look at where you'll use the connector. If it's wet or very hot, pick ones that can handle water or heat.

Look at Strength: Check if the connector is strong and made of good stuff. It should handle stress and shaking in cars.

Make Sure It Fits: The connector should fit with other parts in your car system without problems.

Read Maker's Guide: Always look at what the maker says for using it right.

What Shows a Bad Connector?

Finding bad automotive electrical connectors types early stops bigger car problems. Watch for these signs:

Power Problems: Lights flicker or power cuts mean a loose or rusty connector.

See Rust or Breaks: Rust, color change, or breaks show it might not work well.

High Resistance: Use a tester to see if resistance is too high, which means bad links.

Feels Hot: If it's hot, it might be taking too much power.

Weird Noises/Smells: Buzzing sounds or burning smells near connectors show issues.

By knowing these signs, people can keep their car's electrical connectors working well.

Picking the right car wiring connector is very important. It helps keep a car's electrical systems safe and working well. Each type of connector has special features and benefits. You need to think about how they fit, how strong they are, and what you need them for. By choosing the best connectors, you can make your car systems last longer and work better.

"Choosing the right electrical connectors for your project is a decision that should not be taken lightly."

This shows why picking carefully is key for smooth running and safety. Using the right connectors makes cars work better and more reliably.

See Also

Exploring HSD Connectors in the Automotive Sector

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors