Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in car systems, ensuring effective communication between your vehicle's electrical components. Without high-quality connectors, you may encounter numerous electrical issues. Connectors in cars tend to fail more frequently than those in airplanes, highlighting their significance for your vehicle's performance. By understanding the various types of automotive electrical connectors, you can maintain your car's safety and functionality. Reliable connectors contribute to the longevity and dependability of your vehicle.

Understanding different car connectors is key to keeping your car's electronics working well. These connectors help parts talk to each other, making driving smoother. Let's look at some common and special car connectors.

Blade Connectors are very popular in cars. They are simple and work well. They have a flat metal piece that fits into a slot. This makes sure power moves safely between parts.

Pin Connectors are also common in cars. They have pins that go into sockets. They're great for many connections like in engine controls or music systems. They're easy to use, so mechanics like them.

Butt Connectors join two wires together end-to-end. They look like tubes and need crimping to hold wires tight. They're good for fixing or adding to wire bundles, giving strong connections.

Weatherproof Connectors handle tough weather well. You find them where there's water, dirt, or heat. They have seals to keep stuff out, protecting the car's electronics from harm.

High-Temperature Connectors are needed where it's hot. They can take high heat without failing, often near engines or exhausts. Using these keeps connections safe even when it's really hot.

Standards and Specifications

Knowing the rules for car connectors is important. These rules make sure connectors work well in cars. By following them, you pick safe and good connectors.

Industry Standards

Overview of Key Standards

Car connector rules help ensure quality. Groups like ISO and SAE set these rules. They cover how connectors are made and how strong they are. For instance, ISO 19642 tells what cables need to be tough.

Importance in Automotive Applications

In cars, following these rules is very important. They make sure connectors can handle stress and heat. By using them, your car's electronics stay safe and work right.

Manufacturer Specifications

Examples of Leading Manufacturers

Top companies like Waytek and Amphenol Sine Systems are big in the connector market. They make many kinds of connectors for cars. These companies focus on making good products that improve car performance.

How Specifications Impact Connector Selection

Company details matter when picking connectors. They tell you what a connector can do, like its strength against heat or water. Knowing this helps you choose the right one for your car.

Practical Tips and Troubleshooting

Picking the right automotive electrical connectors types is important. It helps your car work well. Here are some easy tips.

Picking the Right Connector

Choosing the right connector keeps your car's wires working. Think about these things:

Things to Think About

Mechanical Needs: Check if it fits your car parts. A good fit stops problems and keeps things steady.

Weather Conditions: Where will you use it? Will it see heat or rain? Use weatherproof ones for tough spots.

Electric Needs: Look at how much power it can take. Make sure it handles your car's needs without getting too hot.

OEM Fit: OEM connectors fit perfectly in cars. They help parts talk to each other easily.

Strength: Pick strong connectors that last long. This helps your car's wires stay good for a long time.

Mistakes to Avoid

Skipping Details: Always check what the connector can do. Wrong ones cause trouble.

Ignoring Weather: Not thinking about weather can break them fast.

Buying Cheap Ones Only: Cheap ones might cost more later because they break often.

Fixing Connector Problems

Even with good connectors, issues happen sometimes. Fixing them is key.

Spotting Common Issues

Loose Parts: See if any part is not tight enough. Loose parts make electric problems happen sometimes.

Rusty Bits: Check for rust, especially where it's wet often. Rust stops electricity from flowing well.

Broken Covering: Look for cracks in covers of wires. Broken covers can cause short circuits.

Worn Out Connectors: Over time, they wear out from use a lot.

Fixes and Good Habits

Check Often: Look at connectors regularly to catch issues early.

Use Right Tools: When fixing or changing them, use proper tools to avoid harm.

Protect Them Well: Use sprays against rust to keep them safe from damage.

Change Old Ones Fast: Swap old ones quickly for new ones that work better.

By knowing these tips and fixes, you keep your car's wiring system strong and reliable with the right care of its electrical connections.

Picking the correct connector is key for your car's safety. Good connectors keep things working well, like music players and engines. Look at rules and maker details when choosing. These help you pick the best ones for your car. Using the right connectors makes your car last longer. Choosing wisely now stops big problems later, keeping everything in your car running well and smoothly.

See Also

Exploring HSD Connectors in the Automotive Sector

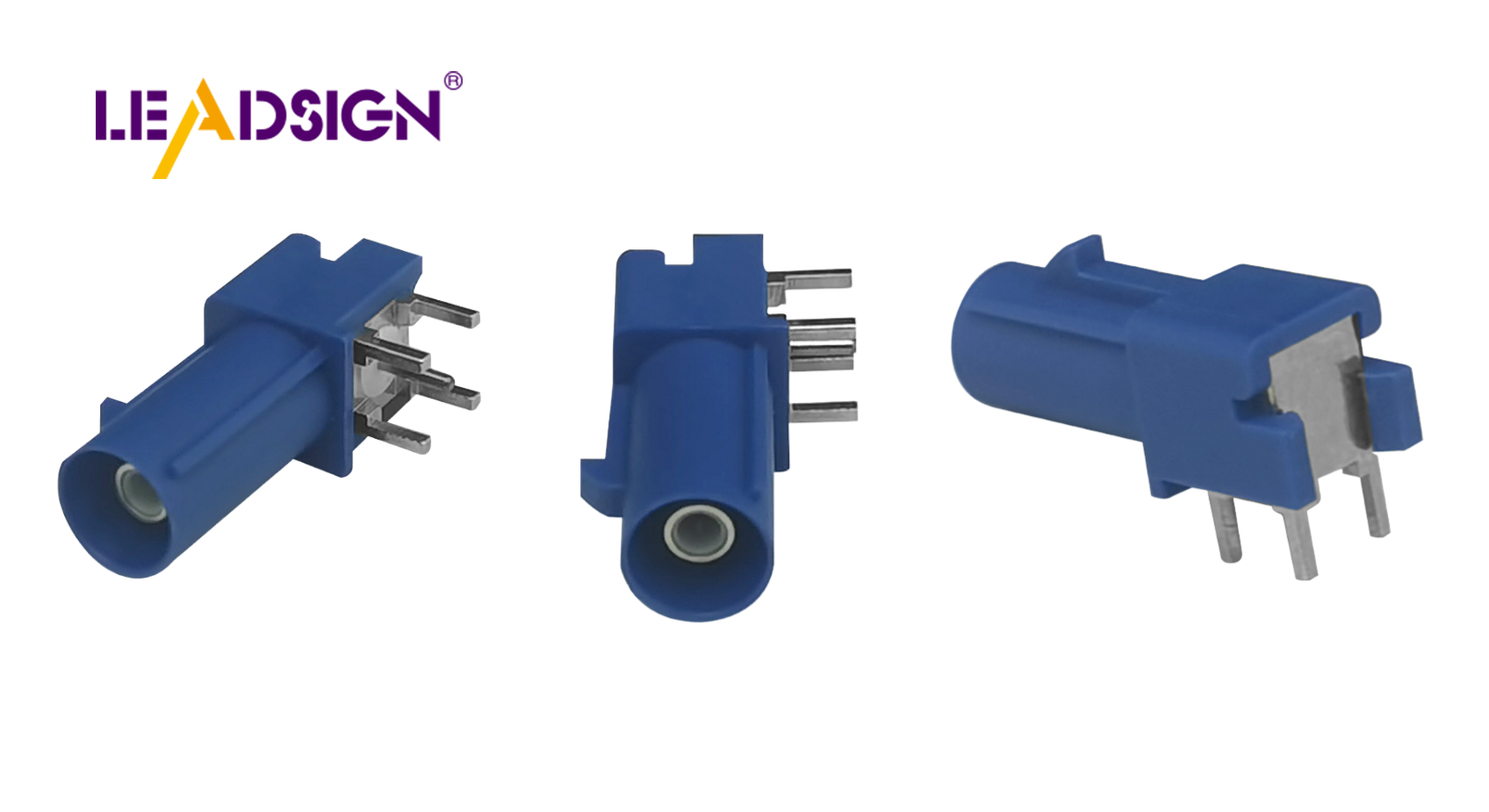

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors