Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a crucial role in vehicles, ensuring optimal performance and safety. There are various types of automotive connectors, each designed to meet specific needs and conditions. Connector failures can occur due to several factors, such as the number of pins, environmental conditions, and frequency of use. Different designs of connectors have varying probabilities of failure. Temperature also impacts their performance. Understanding these factors is essential for selecting the best connectors to ensure a vehicle operates efficiently.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are important in cars. They link electronic parts so they can work together. These connectors have different shapes and sizes for various car needs. They help power and signals move smoothly, making sure cars run well and safely.

Why are they essential in automotive systems?

Car electrical connectors keep vehicles working reliably. They connect different systems, allowing them to share power and information. Without these connectors, car parts might not work right, causing problems or dangers. Picking the right connectors is key for good car performance.

Basic Components of Connectors

Pins and Sockets

Pins and sockets are main parts of car connectors. Metal pins fit into sockets to make a strong connection. This setup helps power and signals move between parts easily. The quality of pins and sockets affects how well the connector works.

Housing and Insulation

Housing and insulation protect pins and sockets. The housing covers them from things like water or dust. Insulation stops electrical shorts, keeping connections safe. Together, they make sure car connectors last long and work well.

Types of Automotive Electrical Connectors

Car electrical connectors help cars work well and safely. Each type has a special job, making sure car parts connect right. Knowing these types helps pick the best one for each use.

Blade Connectors

Characteristics and Applications

Blade connectors are also called spade connectors. They have a flat metal piece that fits in a slot. These are easy to use in cars because they are simple. They connect wires to switches or relays for low power jobs. You can disconnect them quickly, which is good for fixing or changing often.

Common Manufacturers

Some companies make great blade connectors. TE Connectivity and Molex are famous for strong products. They offer many blade connectors to match different car connector needs.

Ring and Spade Terminals

Characteristics and Applications

Ring and spade terminals connect wires to blocks or posts in cars. Ring terminals have round ends that go over bolts, making strong connections. Spade terminals have forked ends for easy on-and-off use. They are used in battery links where strong connections matter.

Common Manufacturers

Companies like Panduit and 3M make good ring and spade terminals. Their products last long even in tough car conditions. They offer many sizes to fit different car connector needs.

Butt Connectors

Characteristics and Applications

Butt connectors join two wires end-to-end securely with insulation. They're used in car wire groups where space is tight but many wires need joining. Some types shrink with heat to keep out water.

Common Manufacturers

Top makers of butt connectors include Delphi and Amphenol. Their products meet hard car connector needs easily, so they're liked by car experts.

Special Connectors

Special connectors help cars work well in tough spots. They are made to handle hard situations like bad weather or very hot places. Knowing these connector types helps pick the right one for each job.

Weatherproof Connectors

Weatherproof connectors keep car parts safe from things like rain and dirt. They stop water and dust from messing up connections, which can cause problems. These connectors stay sealed tight, so they work even when it's wet or dirty outside.

Uses: Found in outside lights, engine areas, and other exposed spots.

Good Points: They block water well, stopping rust and breaks.

"Sealed car connectors stop moisture and dirt from getting inside."

Makers use stuff like silicone or rubber to seal them better. This keeps them strong and working for a long time.

High-Temperature Connectors

High-temperature connectors are needed where it gets really hot. They don't melt or break when it's super warm. In cars, you find them near engines or exhausts where it’s hottest.

Uses: Used in engine parts, exhaust pipes, and hot zones.

Good Points: They keep working even when super hot, avoiding problems.

"Heat affects how they work. Knowing this helps pick the best ones."

These connectors often use ceramic or special plastic that handles heat well. This makes sure they work great in tough places so cars run their best.

Standards and Specifications

Knowing the rules for car connectors is important. It helps cars work well and stay safe. These rules help pick the right connectors for each job, making sure they fit and work right.

Industry Standards

Industry rules set how good car connectors should be. They make sure connectors are safe, strong, and work well.

ISO Standards

The International Organization for Standardization (ISO) makes global rules. These rules ensure car connectors can handle tough conditions. They check things like material strength, electricity flow, and heat or water resistance.

"Car connectors link different electrical parts in your vehicle." - Connector Experts

SAE Standards

The Society of Automotive Engineers (SAE) gives extra rules for cars. SAE rules deal with problems like shaking, temperature changes, and chemicals. They help make strong connectors that last in tough car places.

Manufacturer Specifications

Besides industry rules, makers have their own guidelines to meet different needs.

OEM Requirements

Original Equipment Manufacturers (OEMs) need special things from car connectors. Their guidelines make sure connectors fit the car's systems and do their job well. OEMs give details on connector shape, materials, and how they should work.

Key Points:

Fit with car systems

Strong under certain conditions

Follow safety laws

Aftermarket Considerations

Aftermarket parts also need to follow some guidelines to work right in cars. These parts must fit many car types easily. Aftermarket guidelines focus on easy setup, working well, and being affordable.

Considerations:

Fit many models

Easy to set up

Good price

"Car electrical connectors are made just for auto systems." - Dfliq

By following these rules, makers ensure car connectors work safely and keep cars running smoothly.

Picking the right car connector is very important. It affects how well the car works and stays safe. ISO Standard 10487 and SAE Standard say to choose connectors by pin setup and color.

"Good connectors keep cars working well and safely."

Knowing these rules helps car parts work best. Choosing the right connector makes cars run better and stops problems, keeping driving smooth and safe.

See Also

Exploring HSD Connectors in the Auto Sector

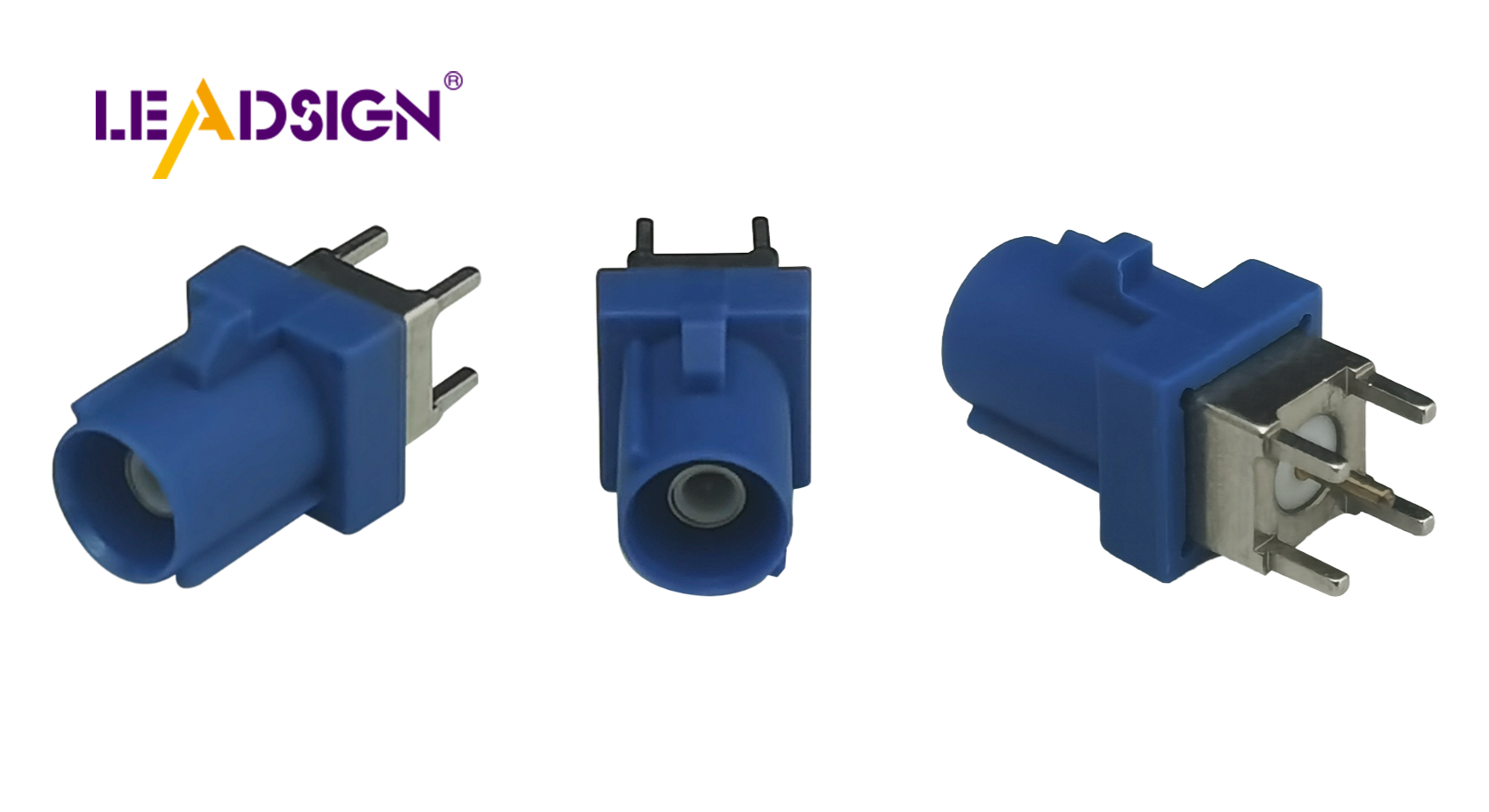

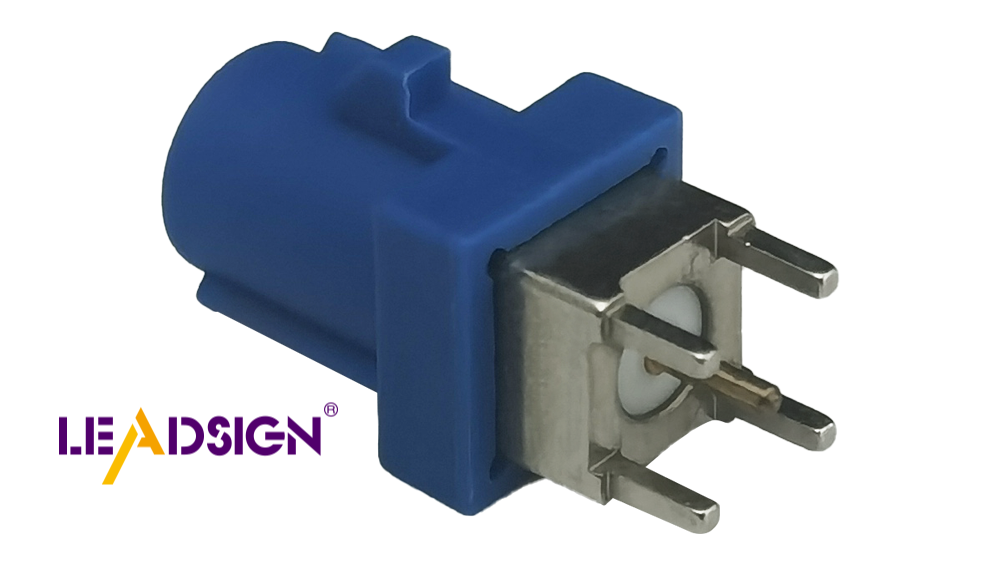

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors