Understanding Automotive Wiring Connector Types

Automotive electrical connectors types play a vital role in modern vehicles. They ensure that electrical systems function efficiently and safely. These connectors securely link various components, reducing the likelihood of issues. Failures in connectors occur more frequently than in plain wiring, highlighting their importance for vehicle safety and performance. Understanding these types of connectors helps us appreciate their significance in automobiles.

Overview of Automotive Electrical Connectors Types

Definition and Purpose

What are Wiring Connectors?

Wiring connectors are key parts in car electrical systems. They link circuits, letting signals pass easily. Each connector has a male (plug) and female (socket) part. The design depends on use. High-current connectors have bigger pins for better contact. Materials like copper, brass, or bronze make them conductive and rust-resistant.

Importance in Automotive Systems

Car connectors ensure all parts work well together. They connect circuits without causing problems that can affect performance. Without them, cars would not work right since they help with engine control and safety features.

Basic Components of Connectors

Housing

The housing is the outer shell protecting inside parts. It keeps the connector safe from heat, moisture, and stress. Made from strong materials, it ensures the connection lasts long.

Terminals

Terminals are metal pieces inside that carry signals. Made from copper or brass, they conduct electricity well and resist rusting. Their design varies with pins or blades fitting into sockets for a firm link.

Seals

Seals protect connector insides from water, dust, and dirt. They keep connections secure even in tough conditions. Usually made from rubber or silicone, seals stay flexible to protect over time.

Types of Automotive Electrical Connectors

Knowing different automotive electrical connectors is important. It helps cars work well. Each type has its own job, good points, and bad points.

Blade Connectors

Features and Applications

Blade connectors are also called spade connectors. They use a flat piece to connect things. These are common in cars because they are simple and easy to use. They fit into slots for a strong connection. Blade connectors are used where you need to unplug quickly, like fuse boxes.

Advantages and Disadvantages

Advantages:

Simple to plug in and out.

Stay connected without falling out easily.

Come in many sizes for different wires.

Disadvantages:

Can get loose if there's a lot of shaking.

Only good for certain uses because of their shape.

Pin Connectors

Features and Applications

Pin connectors have a pin (male) and hole (female). They join together tightly. These are used when you need a strong link, like in engine parts.

Advantages and Disadvantages

Advantages:

Hold tight so they don't come apart easily.

Good for places that shake a lot because they lock in place.

Carry more electricity than other types.

Disadvantages:

Harder to put on or take off than blade ones.

Cost more because they are made carefully.

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end. They're used a lot when fixing car wires. They crimp wires together for a smooth path for electricity.

Advantages and Disadvantages

Advantages:

Easy way to join two wires strongly.

Hold tight so they don't pull apart.

Great for lasting connections in car systems.

Disadvantages:

Hard to take apart once joined, not flexible.

Need special tools to put on, which might be hard to find.

Ring and Spade Connectors

Features and Applications

Ring and spade connectors are special. They have a unique shape. These connectors use a ring or spade end to attach tightly to screws or bolts. This makes them very stable, which is important for cars.

Ring Connectors: These have a round end that fits over screws. They make strong connections that last. Often used for grounding, they stop accidental disconnections in car systems.

Spade Connectors: Also called fork connectors, these slide under screws. They are easy to put on and take off. This makes them good for places where wires need frequent changes, like switches.

Advantages and Disadvantages

Knowing the good and bad points of ring and spade connectors helps pick the right one for cars.

Advantages:

Secure Connection: Both types connect well. Rings stay fixed, while spades come off easily but still hold tight.

Versatility: They come in many sizes and materials for different wires and conditions, fitting various car needs.

Ease of Use: Spades are quick to install or remove, saving time during fixes.

Disadvantages:

Limited Flexibility: Rings need full screw removal to disconnect, which can be slow if changes happen often.

Potential for Loosening: Spades might loosen if not tightened well, causing electrical problems in cars.

Picking the Right Connector

Choosing the right connector is important for cars to work well and stay safe. This part will help you know what to think about and what mistakes not to make when picking connectors.

Things to Think About

When choosing from different automotive electrical connectors, consider these things:

Electrical Needs

Current Capacity: Make sure the connector can handle the power. Too much power can cause it to get too hot and break.

Voltage Rating: Pick connectors that match how much electricity your car uses so nothing breaks.

Signal Integrity: For sending data, choose connectors that keep signals clear without messing them up.

Environment Conditions

Temperature Range: Pick connectors that can handle how hot or cold it gets in your car. If it's too hot or cold, they might not work well.

Moisture Resistance: Choose connectors with seals to keep water out, especially if they're outside.

Vibration Resistance: Near engines where there's a lot of shaking, use connectors that stay put even when moving.

Mechanical Needs

Durability: Choose strong connectors that won't break easily.

Ease of Installation: Think about how easy it is to put on and take off, especially in small spaces.

Size and Shape: Make sure the connector fits where it's supposed to go.

Mistakes Not to Make

Avoiding common mistakes saves time and trouble with automotive electrical connectors:

Wrong Size

Mismatched Sizes: Using wrong-sized connectors can cause bad connections and problems.

Overlooked Specs: Always check what the maker says so everything fits right.

Wrong Materials

Material Mismatch: Using wrong materials can make them rust and stop working well.

Ignoring Environment Fit: Make sure materials are good for where they'll be used, like near chemicals or saltwater.

Picking the right connector means thinking carefully about these things. By knowing what your car needs and avoiding mistakes, you can have good working electric parts in cars.

Choosing the right automotive wiring connector is very important. It helps cars work well and stay safe. Each type of connector has a special job. Picking the right one stops electrical problems.

Think about everything: Look at power needs, weather, and how strong it must be. This makes sure it works well for a long time.

Learn more if needed: For tough jobs, ask experts or read more to choose wisely.

By knowing these things, people can make their car's electrical parts better. This keeps them working and reliable.

See Also

Exploring HSD Connectors in the Automotive Sector

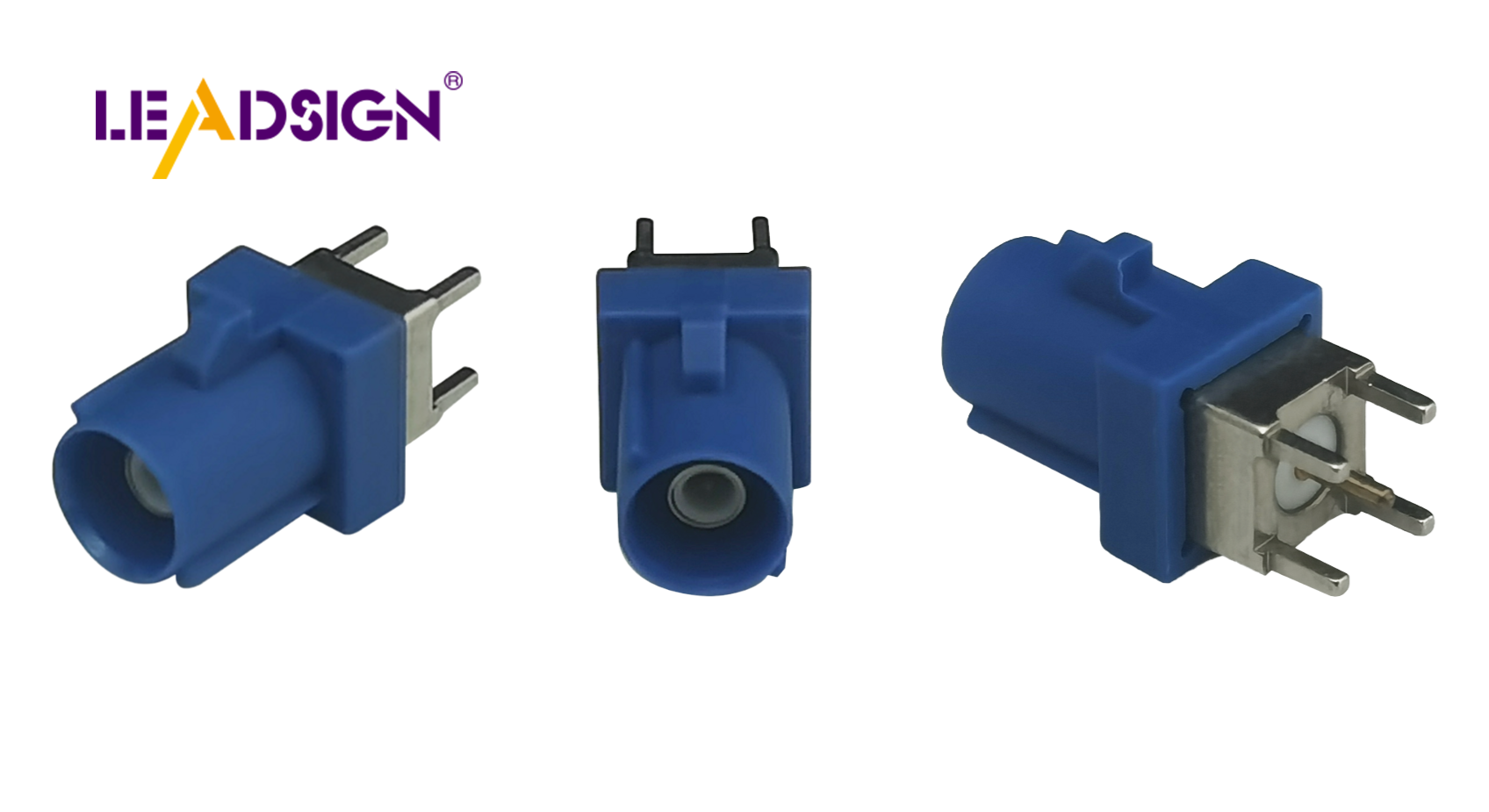

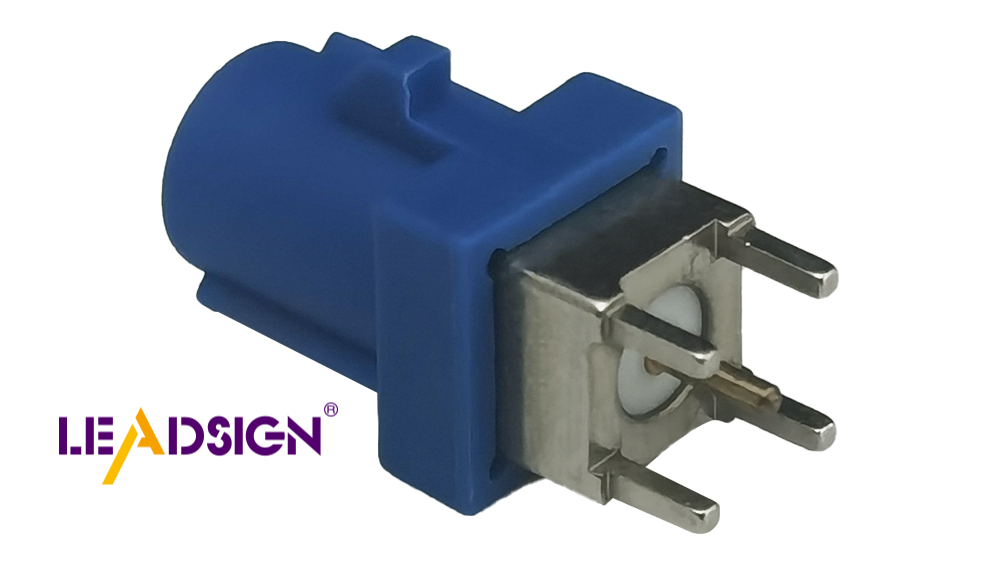

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors