Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in modern vehicles. They facilitate communication between circuits and are integral to the vehicle's electrical system. These connectors consist of four components: contacts, shell, insulator, and additional features. They are designed for optimal connectivity, which is vital for both vehicle safety and performance. Connectors tend to fail more frequently than aircraft wiring, highlighting their significance. Understanding the various automotive electrical connectors types is essential for selecting the appropriate one for each application, ensuring the longevity and efficiency of vehicle systems.

Types of Automotive Wiring Connectors

Blade Connectors

Features and Applications

Blade connectors, also called spade connectors, are common in cars. They have a flat metal piece that fits into a slot. This makes them easy to connect and disconnect. They are good for places where you need to change parts often. You can find blade connectors in car radios, lights, and other electric parts.

Advantages and Disadvantages

Blade connectors have many good points. They give a strong connection for steady electricity flow. You can install or remove them quickly, saving time on repairs. But they also have downsides. Over time, they might get loose in shaky places. If not checked, this can cause power problems.

Pin Connectors

Features and Applications

Pin connectors are another important type for cars. They have pins that fit into sockets for a stable link. This makes them great for important systems like engines and sensors. Pin connectors work well where strong connections are needed.

Advantages and Disadvantages

Pin connectors give a firm connection that stays put. This helps keep the car's electric system reliable. But putting them in is harder than blade connectors because pins must line up right, which takes more time.

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end with a tube shape needing crimping to hold wires tight. They're used when you need wires to stay connected long-term like under dashboards.

Advantages and Disadvantages

Butt connectors make strong links that last long, which is good for reliability over time. They're easy with the right tools but hard to undo once crimped if changes are needed later on; bad crimping may cause weak links or electric failures.

Other Car Wire Connectors

Pigtail Connectors

Pigtail connectors are important in car wiring. They join wires to parts, keeping the connection steady. These have a short wire with a connector, making it easy to link wires to devices. Technicians use them when direct links are hard, like in small spaces or with fragile parts. Their design makes them flexible and simple to install, so they are popular in car wiring.

Bullet Connectors

Bullet connectors quickly connect and disconnect wires. They have a round shape that fits into a matching socket for a tight hold. This makes them great for places where you unplug often, like lights or gadgets. Their simple design is easy to handle, saving time on setup and fixing. But users must align them right to avoid electric problems.

Crimp Connectors

Crimp connectors are common in cars because they're strong and easy to use. They join wires by squeezing a metal piece around wire ends for a firm hold. This means no need for soldering, which many technicians prefer. Crimp connectors come in different sizes for various wires and uses. They're tough and last long even in bad conditions. Good crimp tools are needed for best results since bad crimping can cause weak links.

Key Features of Automotive Wiring Connectors

Material Composition

Common Materials Used

Car wiring connectors use special materials for strength and work well. Makers often pick metals like copper and brass because they carry electricity well. These metals help electricity move easily, cutting down energy waste. Plastic or rubber covers protect connectors from weather and stop short circuits. Insulated Bullet & Receptacle Connectors show this by giving safe, covered links, making sure electricity flows right.

Impact on Performance

The materials chosen affect how wiring connectors work. Good metals boost power flow, making it efficient. Covers are key to stopping electric problems. They guard against wetness and heat that can rust or ruin them. Insulated Butt & Parallel Connectors stop short circuits, keeping power steady. This mix of stuff helps connectors work well in different settings.

Connector Design

Importance of Design in Functionality

How car wiring connectors are made affects how they work a lot. A good connector fits tight, lowering the chance of coming apart. It also makes putting it in and taking it out easy, which is important for fixing things. The design must fit what it's used for, like small spaces or tough places. Electric Connectors come in many shapes and sizes to match different jobs, showing why design matters.

Design Variations

Car wiring connectors have many designs for different needs. Some lock to stop them from coming loose by accident; others let go fast for easy use. Waterproof ones keep water out, lasting longer in bad spots. Multi-pin types let many wires connect at once, saving space and making systems simple. These designs help connectors fit into various car uses better.

Environmental Resistance

Resistance to Heat and Moisture

Car wiring connectors need to handle hot temperatures and wetness well to work right. Heat-resistant ones don't melt or change shape, keeping them working fine. Moisture-proof ones stop rust that can mess up connections. Sealed types keep water out completely, keeping the link strong even when wet.

Durability in Harsh Conditions

Being tough is important for car wiring connectors in rough places too! They should take shakes, hits, and chemicals without breaking down fast! Strong materials make them last longer so you don't replace them often! Keeping up their job under hard conditions keeps cars' electric parts safe!

Choosing Wiring Connectors

Electrical Needs

Current and Voltage Limits

When picking connectors, know the current and voltage limits. These limits show how much electricity a connector can handle safely. Car connectors must follow rules like USCAR-20 to work right. Picking the right ones stops problems like sparks and shorts that break systems.

Matching with Wire Systems

Matching with wire systems is also key. Connectors need to fit the wire size and type in cars. Wrong matches cause bad links, making noise or wrong circuits start. Right matches keep the car's electric system working well and lower failure risks.

Physical Needs

Connector Size and Shape

Connector size and shape matter a lot when choosing them. They must fit in the car without hitting other parts. Small designs are good for tight spots; bigger ones work where there's more space. Right size and shape make putting them in easy and connections strong.

Easy to Install

Easy installation helps fix things fast. Simple connectors save time and cut mistakes. Features like locks or quick-release help use them better. Technicians like ones needing few tools, fitting securely without hurting performance.

Price and Supply

Quality vs Cost

Balancing quality with cost is common when picking connectors. Good ones might cost more but last longer and work better. It's smart to weigh if spending more now saves money later by avoiding frequent changes.

Finding Good Sellers

Finding good sellers is key for getting quality connectors. Trusted sellers give options that meet standards for different needs and budgets. Building ties with these sellers means getting reliable products, helping keep car systems dependable.

Picking the right car wiring connector is very important. It helps keep vehicle systems working well. Each type, like blade or crimp connectors, has special uses. Car connectors must handle tough conditions and follow rules like USCAR-20. This ensures they work properly. Choosing the right one makes car systems last longer and work better. The correct connector choice greatly affects how reliable a car's electric system is. So, it's a key thing for car experts to think about.

See Also

Exploring HSD Connectors in the Automotive Sector

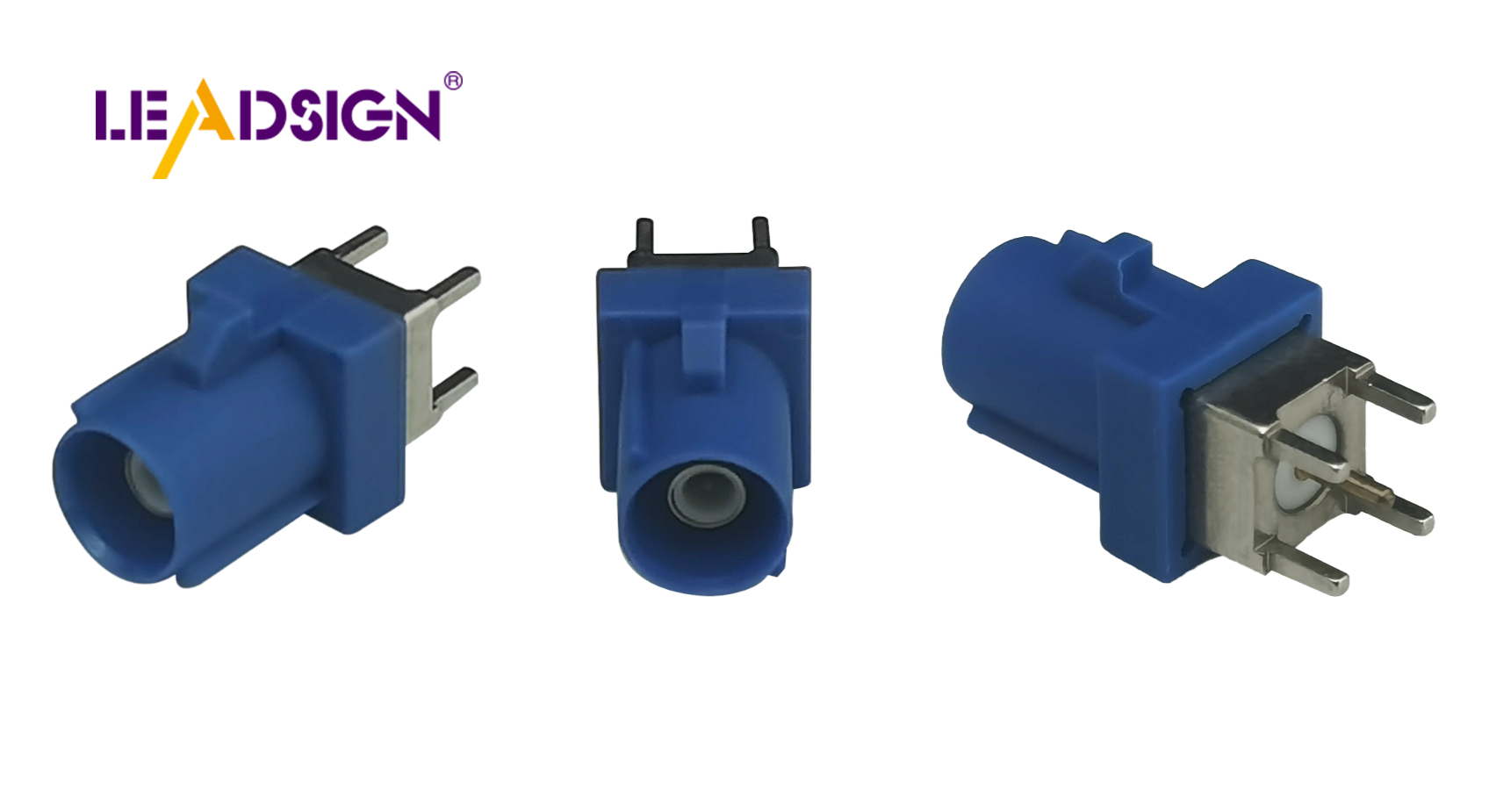

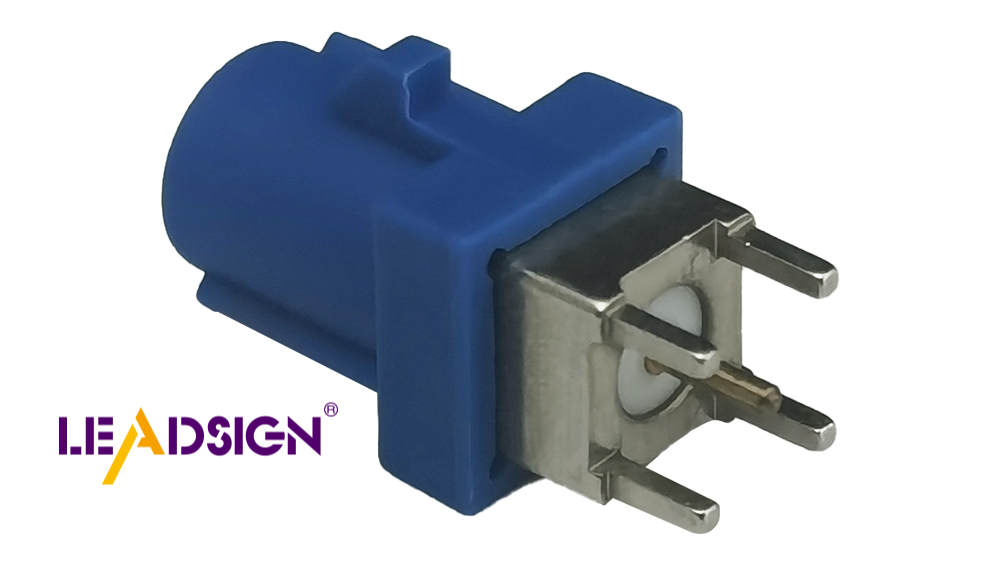

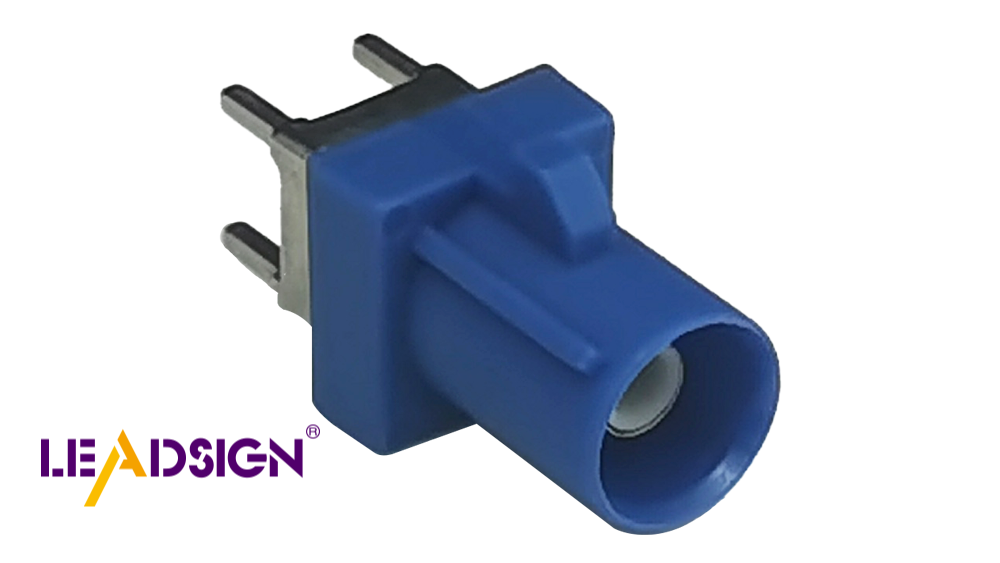

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors