Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in cars. They play a vital role in ensuring smooth electricity flow, which is essential for the proper functioning of vehicles. Selecting the appropriate connector type is key to optimal performance. High-quality connectors enhance system efficiency and longevity, while incorrect choices can lead to issues and setbacks. Automotive electrical connectors types such as blade, pin, and butt connectors are specifically designed to fulfill unique functions in maintaining the optimal operation and safety of vehicles.

Automotive Electrical Connectors Types

Blade Connectors

Features and Applications

Blade connectors, also known as spade connectors, are common in cars. They have a flat metal piece that fits into a slot. This makes connecting easy and fast. They are great for places where wires need to be unplugged often. Blade connectors connect wires to things like switches and fuses in cars.

Advantages and Disadvantages

Blade connectors have good points. They hold wires securely and handle medium electricity well. You can put them on or take them off easily without special tools. But they can get loose from shaking, causing bad connections. They're not always good for high electricity use.

Pin Connectors

Features and Applications

Pin connectors are popular too. They have a pin that goes into a socket for a strong connection. They're used in car wiring to link electronic parts together. Their design keeps connections steady, perfect for important parts like engine controls.

Advantages and Disadvantages

Pin connectors are strong and stable against shaking or weather changes. They lock securely, so they don’t come apart by accident. But they can be tricky to put together because they need exact alignment. Also, they're pricier due to their complex design.

Butt Connectors

Features and Applications

Butt connectors join two wire ends to make one path for electricity. They're used when wires need fixing or extending in cars. They come in different sizes for various wire thicknesses.

Advantages and Disadvantages

Butt connectors give secure links that handle medium to high electricity loads well. You use crimping tools to attach them firmly between wires. But you must crimp correctly; wrong methods cause failures in electric flow. They're not ideal if wires need frequent disconnecting.

Features of Automotive Wiring Connectors

Material Composition

Common Materials Used

Car connectors depend on what they're made of. Makers pick materials like copper, brass, and aluminum for good electricity flow. Copper is great for carrying electricity. Brass, a mix of copper and zinc, conducts well and fights rust. Aluminum is lighter than copper but not as good at conducting.

Scientific Research Findings: Studies on wearable connectors show picking the right stuff is key for lasting use. These findings say material choice really affects how well connectors work in different jobs.

Impact on Performance

What car connectors are made from changes how they work. Copper and brass help electricity move better, saving energy. Rust-proof materials make them last longer in tough spots. Light stuff like aluminum helps cars by cutting weight.

Scientific Research Findings: Research says connectors with different force levels last differently. This shows that what they're made of matters for keeping cars working well.

Connector Design

Importance of Design in Functionality

How car connectors are designed matters a lot. A good design keeps connections tight so they don't come apart by mistake. It also makes putting them together easy and fast, which is important when time counts.

Scientific Research Findings: Making wearable connectors shows design is super important. The study says things like how parts fit together matter for making sure they work right.

Variations in Design

Car connectors have different designs for special needs. Some lock to stay secure; others come off easily if needed quickly. Designs might also keep water out to stop damage from moisture or dirt.

Scientific Research Findings: Data from connector studies show that design differences change how well they work and last. This means thinking about design details is important when making car connectors.

Practical Uses and Thoughts

Best Ways to Install

Needed Tools

To put in car wire connectors, you need special tools. Use wire strippers to take off the wire cover without harm. Crimping tools help attach connectors tightly to wires. Multimeters check if connections work right. Heat guns or soldering irons are for heat-shrink tubes or soldered links, adding safety.

Mistakes to Watch Out For

Avoid mistakes when installing to stop future problems. Make sure wires are stripped just right for good connections. Too much or too little crimping makes bad links, so use the right force. Match connector size with wire thickness for tight fits. Not using heat-shrink tubes can let water in, causing rust and failure.

Keeping Up and Fixing Problems

Finding Common Problems

Regular checks keep car wiring working well. Usual problems are loose links, rust, and broken wires. Look for worn parts like frayed wires or faded connectors; these show overheating or rust. Loose links cause flickering issues, so make sure they're tight.

Fixes and Repairs

Fix problems fast to make wiring last longer. For loose links, re-crimp or swap connectors for a snug fit. Clean rusty connectors or replace them for good flow of electricity. Fix broken wires to stop electric failures. Use grease on links to block moisture and dirt from causing rust later on. Regular checks and quick fixes keep car systems safe and working well.

Knowing different automotive wiring connectors is important for car performance. Each type, like blade, pin, and butt, has its own job and benefits. Picking the right one makes systems work better and prevents problems.

Logical Reasoning: Choosing the right connector isn't just about fitting; it affects how well things work and stay safe. The correct choice can stop expensive fixes and time wasted.

In summary, always think about where you'll use it and what it needs to do. This helps car parts work smoothly and last a long time.

See Also

Exploring HSD Connectors in the Auto Sector

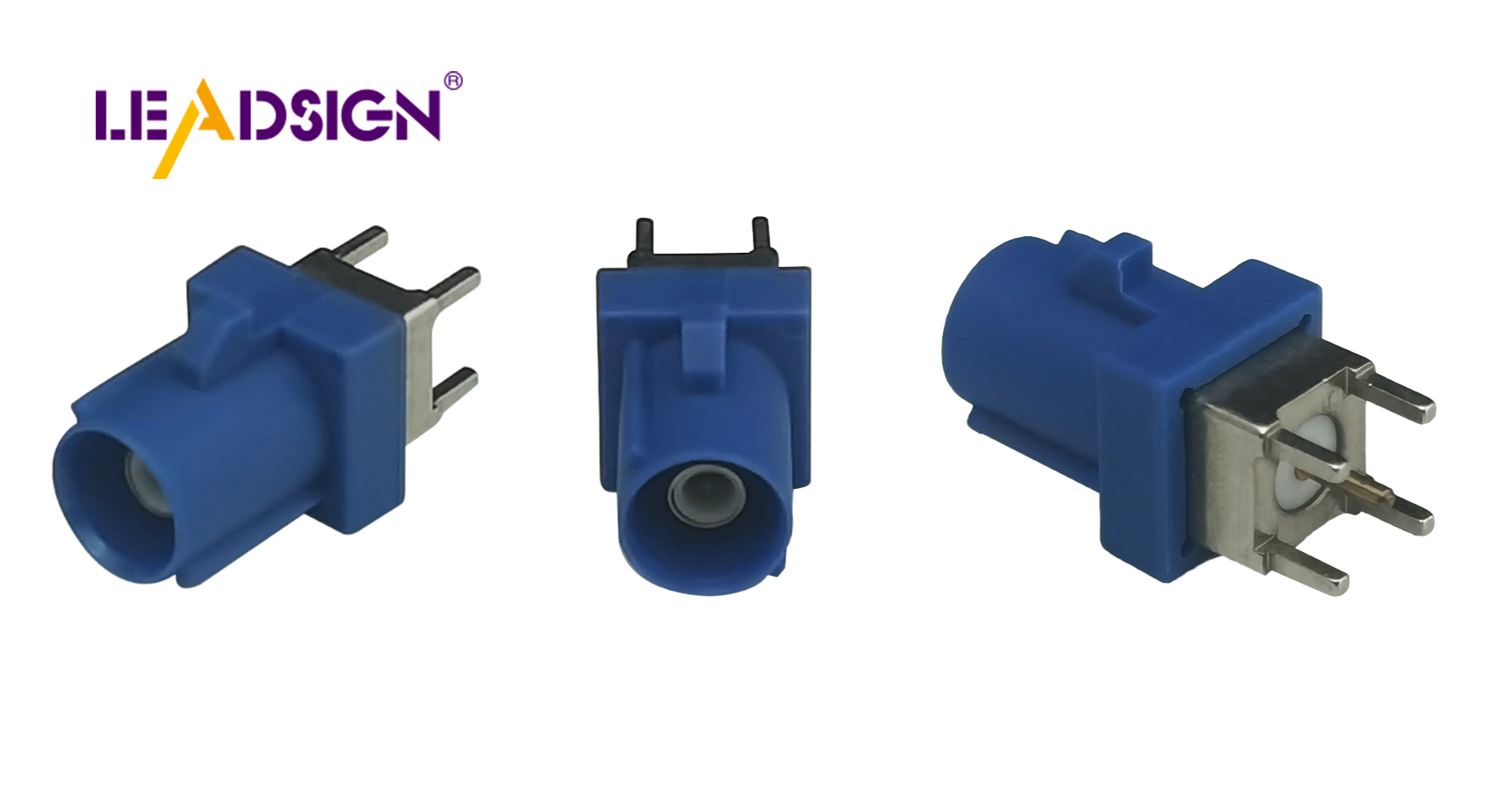

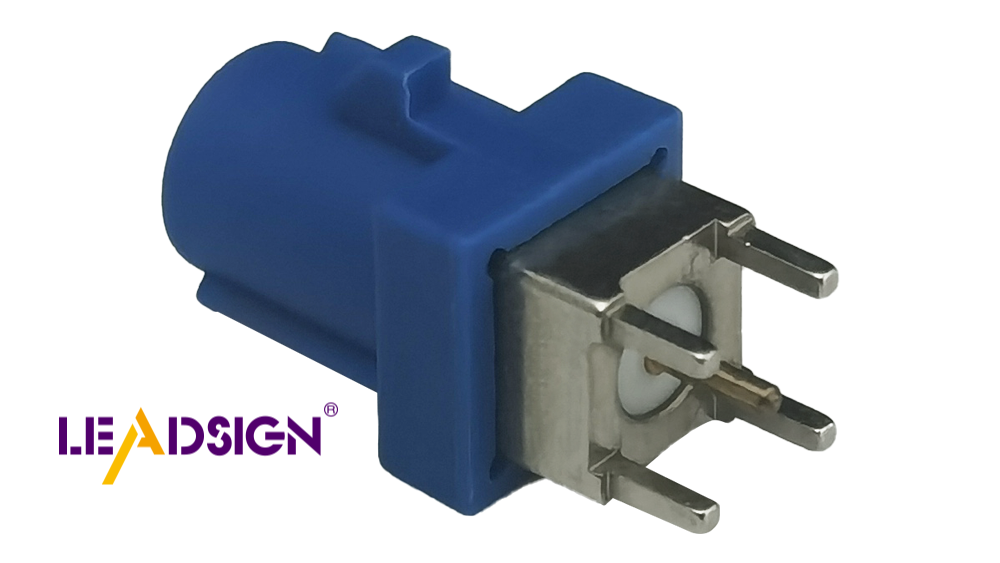

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford's Fakra Connector System