Understanding Automotive Wiring Connector Types

Automotive electrical connectors are crucial for vehicles, ensuring efficient electrical flow necessary for the operation of various car components. These connectors are more prone to failure than wires due to environmental factors and frequent use. There are various automotive electrical connectors types, such as blade, ring, and specialized connectors, each serving distinct functions to enhance vehicle performance and longevity. Understanding these types helps in selecting the most suitable connector to ensure optimal vehicle operation.

Overview of Car Electrical Connectors Types

What are Wiring Connectors?

Wiring connectors are important in car systems. They connect circuits, letting electricity flow smoothly in cars. These come in different shapes, each made for special jobs in cars. By linking wires and parts, they help keep the car's electric system working well.

Why Are They Important?

In cars, wiring connectors make sure electric connections work well. They stop signal loss and keep signals strong, which is key for things like engines and dashboards to work right. Good connectors use materials like gold or silver to cut signal loss and boost performance. Some connectors handle fast data transfer by keeping signals clear.

Main Parts of Connectors

Pins and Sockets

Pins and sockets are the heart of a connector. They link wires so signals can pass through them. The number of pins changes with each connector type. More pins mean better signals and can carry power and data together. This makes them useful for many car uses.

Housing and Insulation

The housing keeps parts safe from weather problems. Car connectors face bumps and shakes, especially in big vehicles. Many have strong locks to stay connected tightly. Strain relief stops wires from bending too much, making them last longer. The housing also keeps out water and dirt, helping connectors last longer.

Types of Automotive Electrical Connectors

Car electrical connectors help power and signals move well. Each type has a special job, helping cars work better. Knowing them helps pick the right one for each use.

Blade Connectors

Features and Applications

Blade connectors have flat metal parts that fit into slots. They're used in cars because they're easy to use and reliable. They connect quickly, good for when you need to fix or change things often. You find them in fuse boxes and lights.

Advantages and Disadvantages

Advantages:

Easy to plug in and out, saving time.

Stay connected well, so they don't fall out.

Cheap and easy to find.

Disadvantages:

Not great where there's lots of shaking; they can get loose.

Can't carry as much power as some other types.

Ring and Spade Connectors

Features and Applications

Ring connectors have round ends that go over bolts. Spade connectors have forked ends that slide under screws. They're used in batteries and places needing strong connections.

Advantages and Disadvantages

Advantages:

Strong hold, good for shaky places.

Simple to put on or take off.

Come in different sizes for various wires.

Disadvantages:

Need tools to put on, taking more time.

Not as flexible for all uses like other types.

Butt Connectors

Features and Applications

Butt connectors join two wires end-to-end. They're used in car wiring fixes, giving safe connections. They come in many sizes for different wires.

Advantages and Disadvantages

Advantages:

Strong connection keeps circuits safe.

Easy with few tools needed.

Works with many wire types in cars.

Disadvantages:

Might need extra cover for tough spots.

Not best if you need to unplug often.

Knowing about car electrical connectors is key for keeping cars running well. Each kind has special features making it right for certain jobs. Picking the right one makes your car's electric system last longer.

Specialty Connectors

Specialty connectors are important in cars, especially in tough places. They keep connections strong even when conditions are hard, helping the car work better.

Weatherproof Connectors

Weatherproof connectors are made to handle bad weather. They stop water and dirt from messing up connections. This is key for keeping connections safe, especially under the hood or near wheels.

Features:

Sealed to block water.

Strong materials that don't rust.

Often have rubber seals for extra safety.

Applications:

Used in outside lights.

Needed for off-road cars facing mud and water.

Common on boats because they resist saltwater.

Weatherproof connectors help car connectors work well even when it's wet or dirty. By keeping out water and dirt, they lower failure chances and make systems last longer.

High-Temperature Connectors

High-temperature connectors work where it's really hot. They're needed where normal ones might break from heat, like near engines or exhausts.

Features:

Made of heat-proof stuff like silicone.

Handle much hotter temps than normal ones.

Often have extra layers to stop heat spread.

Applications:

Used in engine areas with high heat.

Great for parts making lots of heat.

Found in race cars needing top performance.

High-temperature connectors help car connectors stay good in hot spots. Using materials that don't melt easily, they keep working well, cutting down on failures.

Picking the Right Connector

Choosing the right connector for cars needs careful thought. The correct choice keeps the car's electrical system working well and lasting long.

Things to Think About

Electrical Needs

When picking car connectors, know what electricity they need. Each one must handle certain volts and amps. For example, connectors in powerful parts like engines need more volts. Make sure the connector can take the power to stop it from getting too hot or breaking.

Weather Conditions

Weather affects how well car connectors work. Connectors in tough spots, like near wheels, need strong protection from water, dirt, and heat changes. Weatherproof ones with seals keep them safe from these things, so they work even when it's hard.

Mistakes to Avoid

Forgetting Compatibility

A common mistake is not checking if connectors fit. They must match the wires and parts they join. Wrong matches can cause bad connections or damage. Always check if connectors fit with wires and parts for smooth use.

Ignoring Quality Rules

Skipping quality rules can make connectors fail early. Good ones follow rules that make them last longer and work better. Using standard-approved connectors ensures they meet car needs well. Choosing quality over cheapness avoids frequent fixes and dangers.

By thinking about these points and avoiding mistakes, people can pick the best car connectors for their vehicles. This careful choice makes cars safer and their electric systems better, giving drivers peace of mind.

Installation and Maintenance Tips

How to Install Connectors Right

Putting car connectors in the right way is super important. It stops problems later and helps them last longer.

Tools You Need

To put connectors on well, you need some tools. These tools help make sure everything stays connected:

Wire Strippers: Take off the plastic from wires without breaking them.

Crimping Tool: Helps stick connectors to wires tight.

Screwdrivers: Used for turning screws on some connector types.

Multimeter: Checks if the electric connection works right.

Easy Steps to Follow

Do these steps to put connectors on right:

Get Wires Ready: Use wire strippers to take off half an inch of wire cover.

Pick a Connector: Choose one that fits the wire size and job.

Put on Connector: Push the bare wire into the connector and crimp it tight.

Check Connection: Use a multimeter to see if it's working with no breaks.

Make Sure It's Tight: If needed, use a screwdriver to tighten screws so it stays put.

Keeping Connectors Good

Checking connectors often keeps them working well and stops electric problems.

Look Often

Look at connectors regularly to catch problems early:

Look Over Them: Check for rust or damage on wires and connectors.

Test Tightness: Make sure all parts are snug so they don't come loose.

See if They Work: Use a multimeter to check if everything's running fine.

Clean and Swap Out

Cleaning and changing old parts makes them last longer:

Clean Up Dirt: Use a brush or air spray to clean dirt off. For hard dirt, use gentle cleaner.

Swap Bad Ones Out: Change any rusty or broken ones with good new ones that follow rules.

By doing these things, people can keep their car's electric system strong. Taking care of connectors makes cars work better and stay safe too.

Choosing the right car wiring connector is very important. Each kind of connector has a special job. It helps the car work well and stay safe. Following good steps when putting them in or fixing them makes them last longer. Using connectors correctly makes cars more reliable and less likely to have electric problems. Knowing these tips can make your car work better and be safer, so you feel calm while driving.

See Also

Exploring HSD Connectors in the Automotive Sector

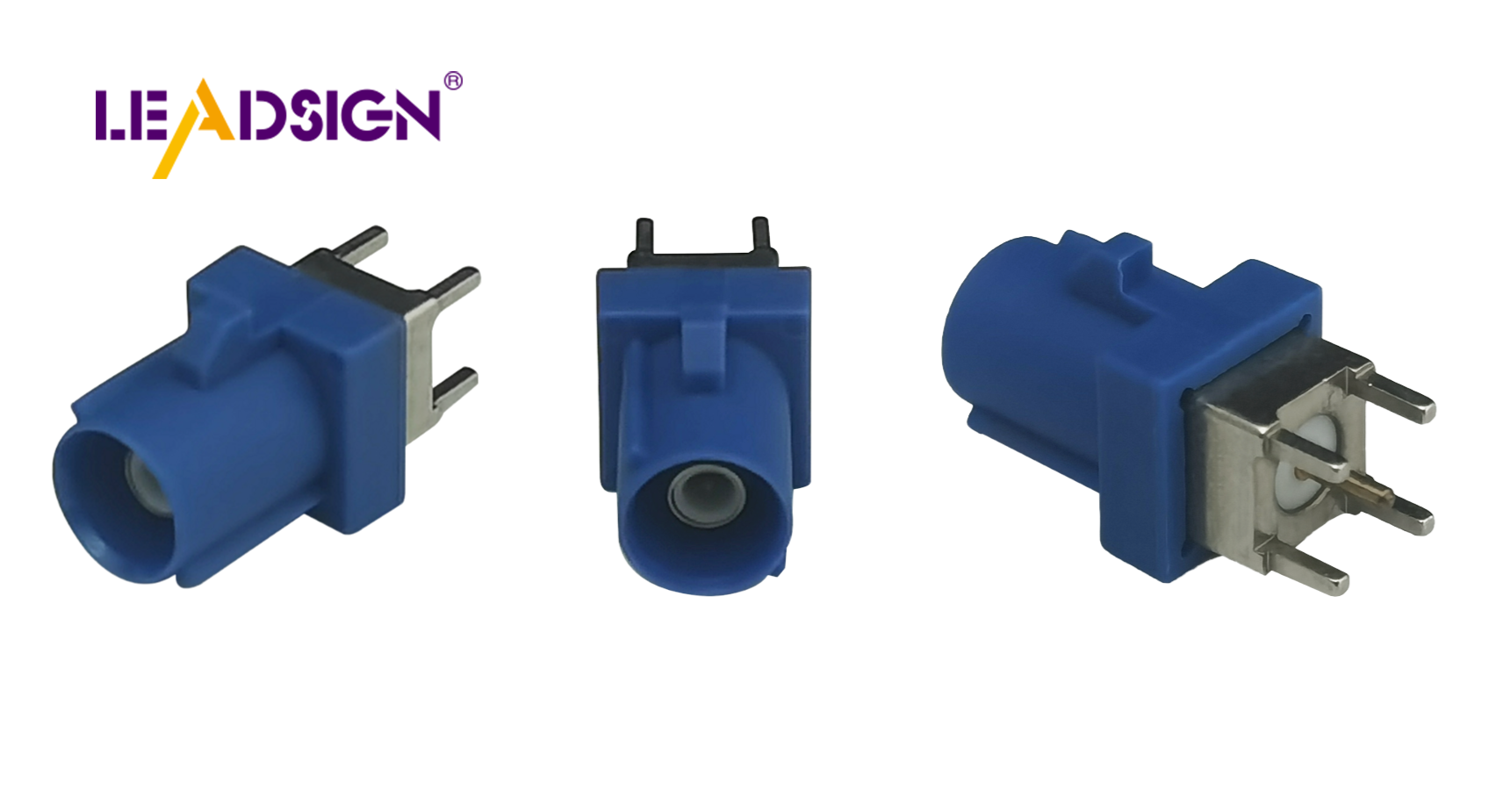

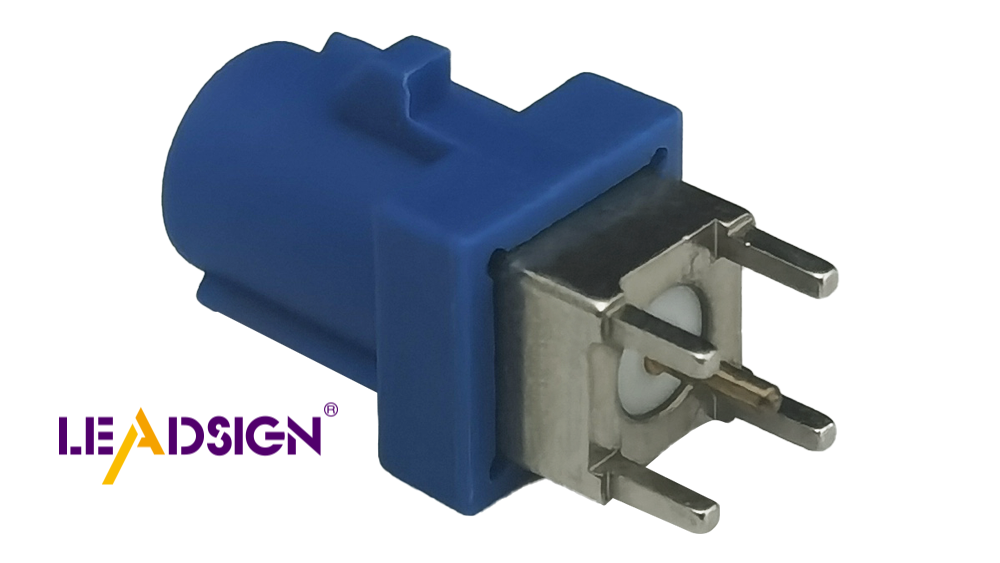

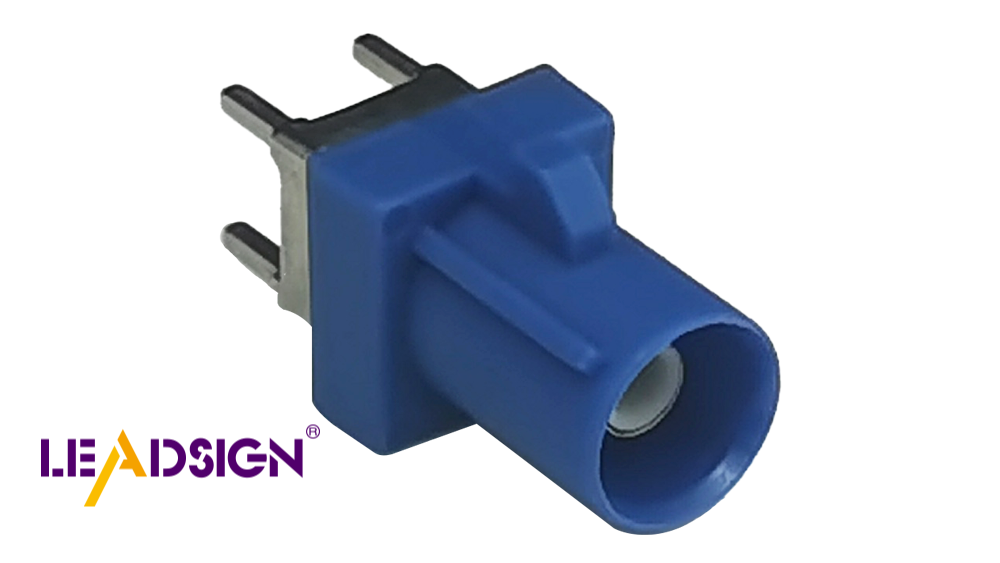

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors