Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial in car systems. They play a vital role in maintaining efficient electrical connections. Without reliable connectors, vehicles may frequently experience electrical issues. Various types of automotive connectors are designed to function uniquely and offer long-lasting performance. Factors such as connector material, temperature resistance, and power capacity influence their effectiveness. Due to their complexity, connectors are more prone to failure compared to standard wires. Understanding the different automotive electrical connectors types is essential for ensuring the safety and proper functionality of a car's electrical system.

Automotive connectors help cars work well. Each connector type has a special job and features for different needs.

Blade connectors are simple and easy to use. They have a flat metal piece that fits into a slot. This makes them good for quick connections, like car lights and fuses.

Blade connectors are easy to install without tools. They connect well but can loosen with vibration. They don't protect much from water or dust.

Pin connectors use pins and sockets for strong connections. They're used in engines and sensors where stability matters.

Pin connectors stay secure in heat and shaking but need special tools to install. They're harder to disconnect, which is tough for frequent fixes.

Butt connectors join two wires together end-to-end. They're great for fixing car wires and come in insulated or not versions.

Butt connectors keep wires tight but need crimping tools. Non-insulated ones only work with copper wires.

Ring and Spade Connectors

Features and Uses

Ring and spade connectors are special because of their shape. They have a metal ring or spade that fits around a bolt. This makes them strong and steady, even when things shake.

Uses:

Ring connectors: Used in battery ends and grounding spots. They hold tight even with high power.

Spade connectors: Found where quick unplugging is needed, like speaker wires.

Both types are easy to put on. You just need pliers or wrenches, so anyone can use them.

Pros and Cons

Pros:

Strong Hold: They fit tightly, so they don’t fall off easily.

Many Sizes: They fit different wire sizes and bolts.

Simple to Use: You don't need many tools to attach them.

Cons:

Hard to Remove: To take off ring connectors, you must remove the bolt first.

Rust Risk: Without cover, they can rust in bad weather.

Key Features of Automotive Wiring Connectors

Material Composition

Common Materials Used

Car connectors use different materials for strength and work well. Makers often choose metals like copper and brass because they carry electricity well. These metals help signals move easily. Plastics like polyamide are used for the outside part. They keep the connector safe from things like water and dirt.

Impact on Performance

The material choice affects how car connectors work. Metals such as copper have low resistance, so energy moves with little loss. This makes the system efficient. Plastics protect connectors from wetness and heat, making them last longer in tough places.

Connector Design

Importance of Design in Functionality

Design is important for how car connectors work. A good design fits tightly, stopping it from coming loose. It also makes putting on and taking off easy, which helps with fixing things. The design must fit what the electrical system needs.

Design Variations

Car connectors come in many designs for different jobs. Some clean themselves to stay connected over time. Others have seals to keep water out. You can change some housings to fit different systems, making them useful in many ways.

Environmental Resistance

Resistance to Heat and Moisture

Car connectors need to handle heat and wetness well to work right. Many use materials that don't get damaged by heat, so they work even when it's hot. Designs that resist moisture stop water from getting in, keeping connections safe from rust or shorting out.

Durability in Harsh Conditions

Being tough is key for car connectors types. They need to stand up against chemicals and shaking around a lot. Strong housings and locks help them stay together, working even when conditions are hard.

Practical Uses and Things to Think About

Picking the Right Connector

Choosing the right connector helps cars work well. When picking one, think about these things:

Things to Think About

Electrical Needs: Know how much power is needed. This makes sure the connector works without getting too hot or breaking.

Where It Will Be Used: Think about where the connector will be used. Heat, water, and chemicals can make it wear out faster.

Material Choice: Pick connectors made from good materials like copper or brass because they carry electricity well and don't rust easily.

Design and Fit: Make sure the connector fits right in your system. A good fit stops it from coming loose and keeps connections strong.

Mistakes to Avoid

Ignoring Details: Not checking what a connector can handle might lead to problems with power or weather resistance.

Wrong Installation: Not installing it right can make it loose or break.

Skipping Maintenance: Checking connectors often helps them last longer and work better.

Tips for Installing

Putting connectors on correctly is key for a safe electrical system. Here are some tips and tools you need:

Best Ways to Install

Clean First: Make sure parts are clean before connecting them to reduce problems.

Tighten Well: Fasten connectors tight enough so they don’t shake loose but not too tight that they break.

Use Covers: Cover open parts to keep water out and stop short circuits.

Tools You Need

Crimping Tools: Needed for attaching connectors tightly to wires.

Screwdrivers/Wrenches: Use these for tightening screws or bolts on connectors.

Multimeter: Helps test if connections work properly by checking electricity flow.

Fixing Common Problems

Even with care, connectors might have issues sometimes. Finding and fixing common problems fast is important.

Spotting Bad Connectors

Look Closely: Check for damage or rust on connectors; melting means overheating.

Test Connections: Use a multimeter to see if electricity flows through; no flow means a broken connection.

Check Tightness: Make sure all parts are tight and not shaking loose.

How to Fix Them

Swap Out Bad Parts: If worn out, replace with new ones.

Clean Rusty Parts: Use cleaner to remove rust for better contact.

Tighten Loose Parts: Secure any that are wobbly to avoid electrical problems.

Knowing how car connectors work helps keep your car's electrical system running smoothly. By picking the right ones, installing them correctly, and fixing any issues quickly, you ensure everything works as it should.

Choosing the right car wiring connector is very important. It helps the car's electrical system work well. Each connector has a special job. Knowing these differences can stop common problems. Using them correctly, like crimping and covering wires, makes them last longer.

Making sure every wire fits in the connector right is hard but important.

To learn more, look for extra information or ask questions to know more about car connectors.

See Also

Essential Guide to HSD Connectors in Auto Sector

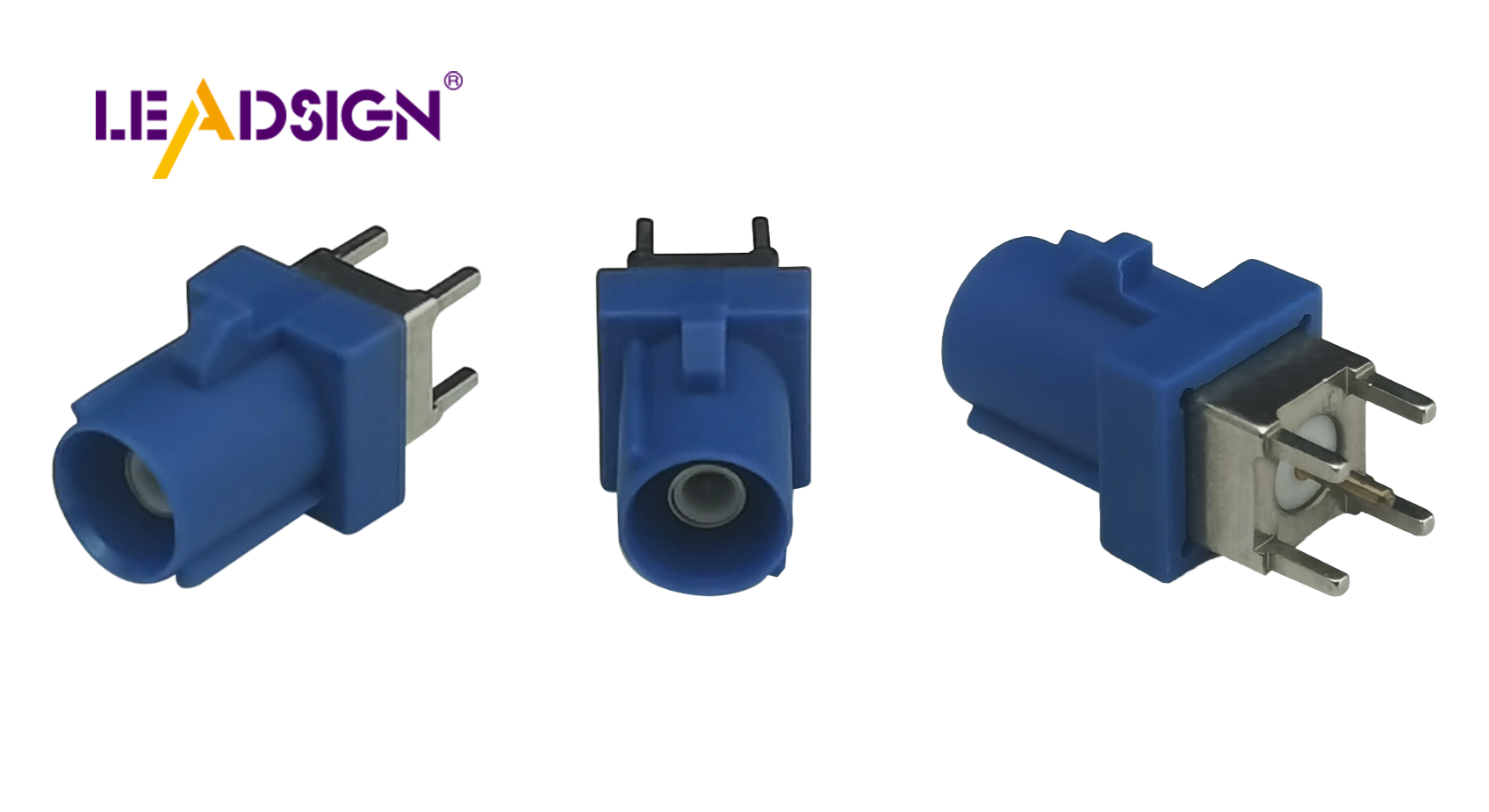

Significance of Fakra Auto Connectors in Modern Cars

Navigating Ford Fakra Connectors