Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial for vehicle systems, facilitating seamless communication between various components. Without reliable connectors, cars frequently encounter issues. For instance, poor electrical contact accounts for 45% of connector problems, highlighting the importance of selecting the appropriate connector. These connectors establish electrical connections and prevent errors in assembly and sizing. Understanding automotive electrical connectors types is essential for maintaining the efficiency and safety of vehicles.

Basic Ideas about Car Wiring Connectors

What are wiring connectors?

Wiring connectors are important in cars. They connect electric circuits, keeping parts linked. These wiring connectors have many shapes and sizes. Each is made for a specific job in a car's electrical system. They help electricity move smoothly, making sure car electronics work well.

Why are they important in cars?

Cars need wiring connectors to work right. They let electric signals move between parts like sensors and lights. Without good connectors, cars might break down or be unsafe. Knowing why these connectors matter helps pick the right one for each job, keeping cars safe and working well.

Main Features

What are they made of?

The stuff used to make car wiring connectors affects how they work and last. Automotive connectors usually have plastic or metal covers. Plastic is light but strong, good for many uses. Metal is better for tough jobs because it can handle rough conditions. The coating on connectors stops shocks and rust, helping them last longer.

How are they designed?

Designing car wiring connectors involves thinking about things like current strength and wire size. These decide if the connector can handle power and fit in the car's space. Connectors should be easy to put in securely, even in small spaces. By planning these details, makers create connectors that meet today's car needs.

Types of Automotive Electrical Connectors

Automotive electrical connectors are key for cars to work well. They help send electric signals so parts can talk to each other. Without them, cars would have big problems with how they run and stay safe.

Blade Connectors

What they are and do

Blade connectors, also called spade connectors, are flat metal pieces that fit into slots. They are simple and easy to use. These connectors hold tight, which is good when there are shakes or bumps. You can quickly take them apart and put them back together during fixes.

Where they're used in cars

In cars, blade connectors join wires in harnesses and fuse boxes. They link wires to things like headlights and tail lights. Because they work well and are easy to use, many car makers choose them.

Pin Connectors

What makes them special

Pin connectors have a pin and a socket for strong links. They handle lots of power and resist water and dirt. Their design keeps electricity flowing smoothly, which is important for power.

How they're used in vehicles

Pin connectors go in engine control units where strong links matter most. They're also in sensors where clear signals help the car run its best.

Butt Connectors

How they're made and work

Butt connectors look like tubes that join two wire ends together. They keep wires safe from outside stuff by covering them up. You squeeze them onto wires so they stay put.

Where you find them in cars

In cars, butt connectors join wires when adding new parts like radios or lights. Many car workers pick them because they make strong connections.

Picking Wiring Connectors

Choosing the right wiring connectors for cars is important. You need to know what makes a connector work well in different situations.

Electrical Needs

Power and strength limits

Car connectors must handle certain power levels. These limits show how much electricity a connector can take without breaking. If a connector can't handle enough, it might get too hot or stop working. Engineers should pick connectors that fit the car's power needs to keep it safe.

Fitting with car parts

Connectors must match car parts perfectly. They need to fit with wires and other pieces already there. If they don't fit right, they can cause bad connections and problems. Making sure they fit keeps the car's electric system working well.

Weather Challenges

Heat and water proofing

Connectors in cars deal with tough weather. They have to stand up to heat and wetness to work right. Bad weather can break them down, causing issues. Weather Effects on Connector Work show why we need strong connectors that keep out dirt and water.

Strong and lasting

Car connectors need to be tough and last long. They face bumps, shakes, and other hard hits. Connector Material Strength shows why using rust-proof stuff is key. Gold moving in solder can make them weak or break them. Using strong materials keeps them working over time.

In short, picking good wiring connectors means thinking about power needs and weather effects. Knowing this helps engineers choose ones that make cars run better and safer.

Choosing the right car wiring connector is very important. OEM automotive connectors make cars work better and safer. They help parts talk to each other, stopping electrical problems.

"Good car connector makers like Eigen choose well to boost cars' basic safety and efficiency."

New connector technology keeps making cars better. Makers use smart ideas and safe plans to keep quality high. This focus on new ideas makes us trust how cars perform. As tech changes, knowing about new connectors helps cars work their best.

See Also

Exploring HSD Connectors in the Auto Sector

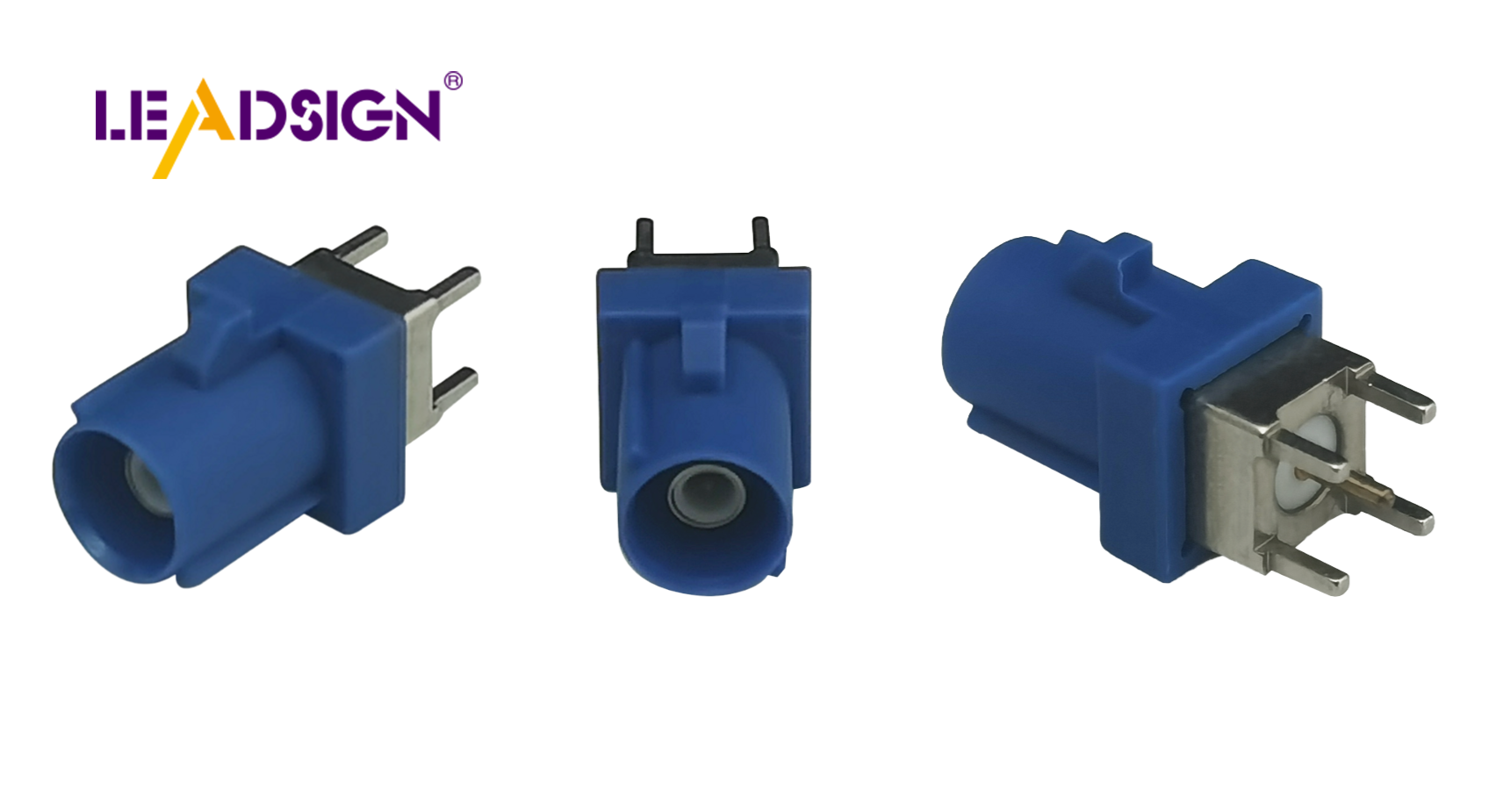

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors