Understanding Automotive Wiring Connector Types

Automotive electrical connectors types are crucial components in a vehicle's electronic system. They play a vital role in ensuring proper connections and maintaining connectivity. Modern vehicles rely on these connectors due to their intricate wiring systems. This highlights the significance of reliable connectors in enhancing car performance. Various types of automotive electrical connectors are designed for specific functions within the vehicle's network. Beyond just establishing connections, these connectors contribute to optimizing the vehicle's functionality and efficiency.

Overview of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are key parts in car electrical systems. They link wires and cables, making sure they stay connected well. These connectors have different shapes and sizes for specific uses in cars. Some are simple like right-angle blades, while others lock tightly to keep water out. Each type is easy to install quickly and safely. These connectors can handle many wiring tasks, from charging batteries with high power to using crimping or soldering for different wires. Wiring connectors are key parts in car electrical systems.

Why are they essential in vehicles?

Car wiring connectors are very important for keeping a car's electronics working well. They help electric signals move smoothly between parts, which is crucial for how the car runs. Without these connectors, modern cars' complex wiring could fail easily. By giving a strong connection, wiring connectors make the car work better and safer.

Basic Components

Terminals

Terminals are the heart of any connector. They let wires join so electricity can flow through them. Terminals come in types like crimp-style that hold even big wires well. These ensure good connections needed for high-power jobs like linking battery packs on forklifts.

Housings

Housings cover terminals to protect them and keep them steady. They stop terminals from coming loose or getting damaged. Housings also insulate against things like moisture and dust, which is vital in cars facing tough conditions.

Seals

Seals make wiring connectors last longer and work better by blocking dirt and water from getting inside connections. Sealed ones are great for cars since they face wetness, dirt, and other stuff that can harm connections. Seals keep these away to help the car's electrical system stay strong over time.

Types of Automotive Electrical Connectors

Knowing about different car electrical connectors is important. Each type has a special job and features for a car's wiring.

Blade Connectors

Features and Uses

Blade connectors are flat and look like blades. They are used a lot in cars. They fit into slots to connect things safely. You often find them in fuse boxes and relay panels. Their design makes them easy to plug in and take out, which is good when you need to disconnect often.

Pros and Cons

Blade connectors have many good points. They connect well with little force, so they last longer. They're simple to install quickly too. But, they don't protect as well from water or dirt as sealed ones do. So, they're not great for wet or dirty places.

Pin Connectors

Features and Uses

Pin connectors have round pins that go into sockets. They're common in car wiring harnesses, joining electronic parts together. Their small size fits many circuits, perfect for complex systems.

Pros and Cons

Pin connectors give strong connections with low resistance. They handle high power well, which is key for big jobs. But their design can be tricky to put together or take apart compared to easier types. Plus, they might need extra sealing from dirt or moisture.

Butt Connectors

Features and Uses

Butt connectors join two wires end-to-end easily. They're used a lot in fixing or extending car wires during repairs.

Pros and Cons

Butt connectors make wire splicing simple with good bonds for electricity flow. But they aren't great where there's lots of shaking since the connection might weaken over time without proper crimping.

Specialty Connectors

Features and Uses

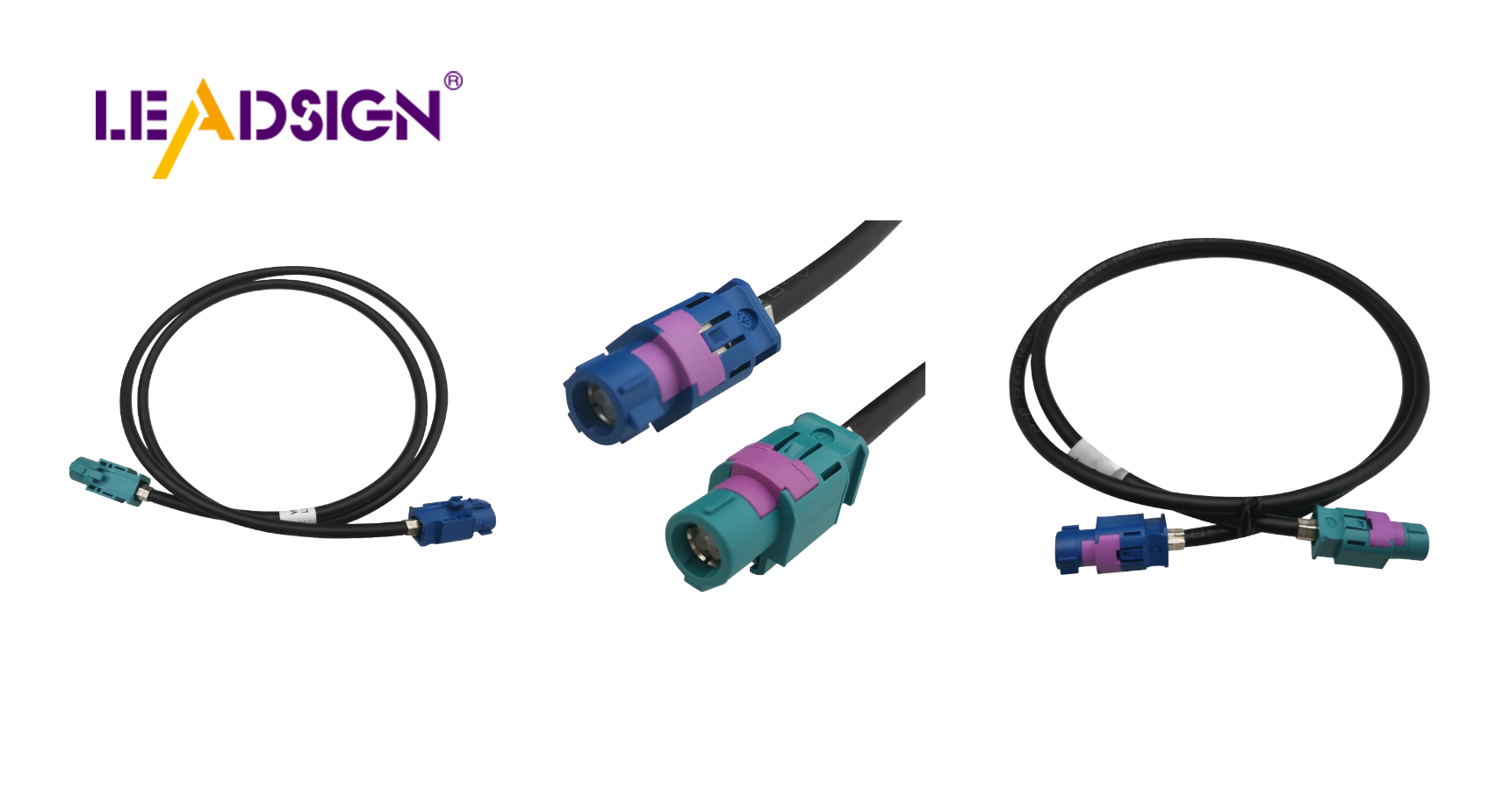

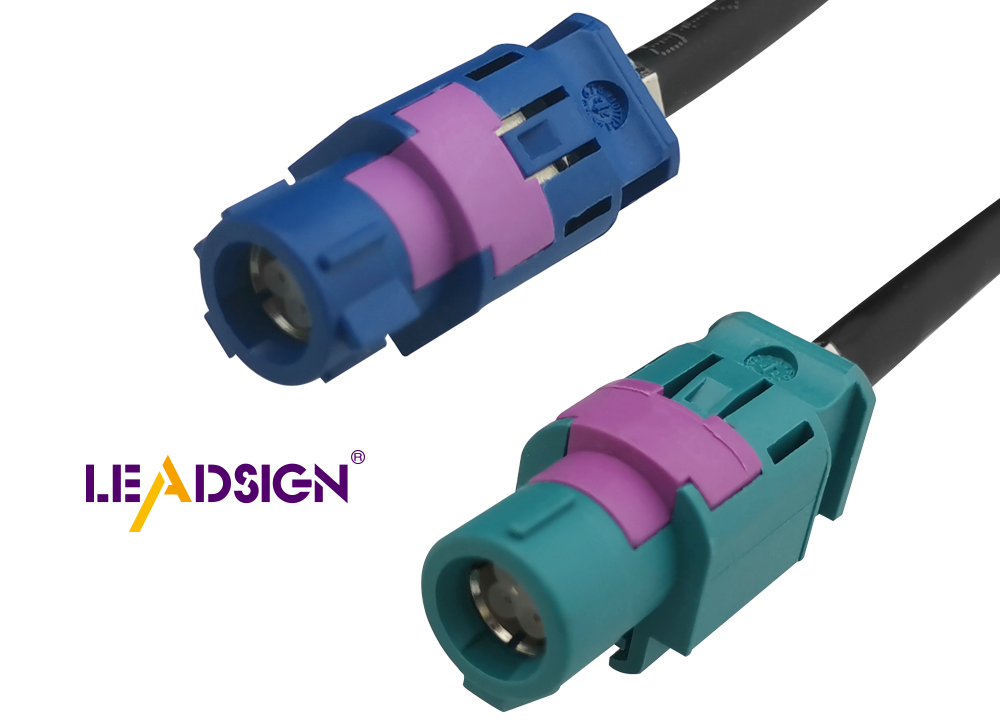

Specialty connectors have special jobs in car systems. They are made for specific tasks. These connectors can handle heat, water, and rust. Many have self-cleaning parts and seals to work well in tough places. Their housings can change shape to fit different setups, making them useful in car wiring.

In cars, specialty connectors are used where exact connections are needed. They work in high-power systems like hybrid and electric cars. These connectors help move power safely and well. They also connect complex parts like music systems and smart driving aids (ADAS). They fit different wire sizes, which is important in new car designs.

Good Points and Bad Points

Specialty connectors have many good points. They protect against things like weather, keeping connections strong for a long time. You can change them to meet design needs, helping cars work better. They support high power levels, great for hard jobs.

But there are some bad points too. Specialty connectors can cost more than regular ones because they are complicated. Putting them in might need special tools or skills, raising costs for work done on them. Also, their special shapes might not fit with other types of connectors easily.

Choosing the right connector is key for a car's electrical system. There are many types, and picking the correct one helps the car work well and stay safe.

Things to Think About

Electrical Needs

Think about what electricity the connector needs to handle. Know how much power it must manage. Big jobs need connectors that can take lots of power without getting too hot or breaking. Always check if it matches what the car needs.

Weather Conditions

Weather matters when picking connectors. Cars face rain, dust, and heat or cold. Pick ones with seals to keep them working in tough spots. Sealed ones stop dirt from getting in, so they last longer.

Matching Car Parts

Make sure connectors fit with car parts. They should match wires and other pieces. Wrong ones can cause bad links and problems. Check if they fit how the car is built and works.

Mistakes to Avoid

Wrong Size

Picking wrong sizes happens a lot with connectors. Too small might overheat; too big might not fit right, causing loose links. Measure first to get the right size for the job.

Bad Material Choice

Material affects how long a connector lasts and works well. Some materials fight rust better than others. For cars, choose strong stuff like nylon or thermoplastic elastomers that hold up in rough places.

Car wiring connectors are important for keeping a car's electronics working well. They make sure connections are strong and help the car run better. Picking the right connector is key for safety and how well the car works. Connectors need to handle heat, wetness, and rust. This keeps connections strong and reliable. For tricky wiring, asking experts is smart. Their knowledge helps choose and set up connectors right. This makes the car work better and last longer.

See Also

Exploring HSD Connectors in Automotive Applications

Significance of Fakra Connectors in Contemporary Cars

Navigating Ford Fakra Connectors